RadiMation Application Note 154: Difference between revisions

No edit summary |

|||

| (20 intermediate revisions by 2 users not shown) | |||

| Line 6: | Line 6: | ||

== Necessary equipment == | == Necessary equipment == | ||

The following devices are necessary to run | The following devices are necessary to run the calibration, verification and EUT test: | ||

* Signal generator | * Signal generator | ||

* Amplifier | * Amplifier | ||

| Line 19: | Line 19: | ||

* Cable drivers with corrections | * Cable drivers with corrections | ||

== | == Tips == | ||

=== | {{Note|If the current unit is shown as uA, it can be changed to dBuA by clicking {{ScreenElement|Units}}, select {{ScreenElement|Current}} and click {{ScreenElement|Edit}} to change this.}} | ||

[[File: | |||

== Define the test level == | |||

=== Create a correction file for the test level === | |||

{{Menu|File|New|Correction}} | |||

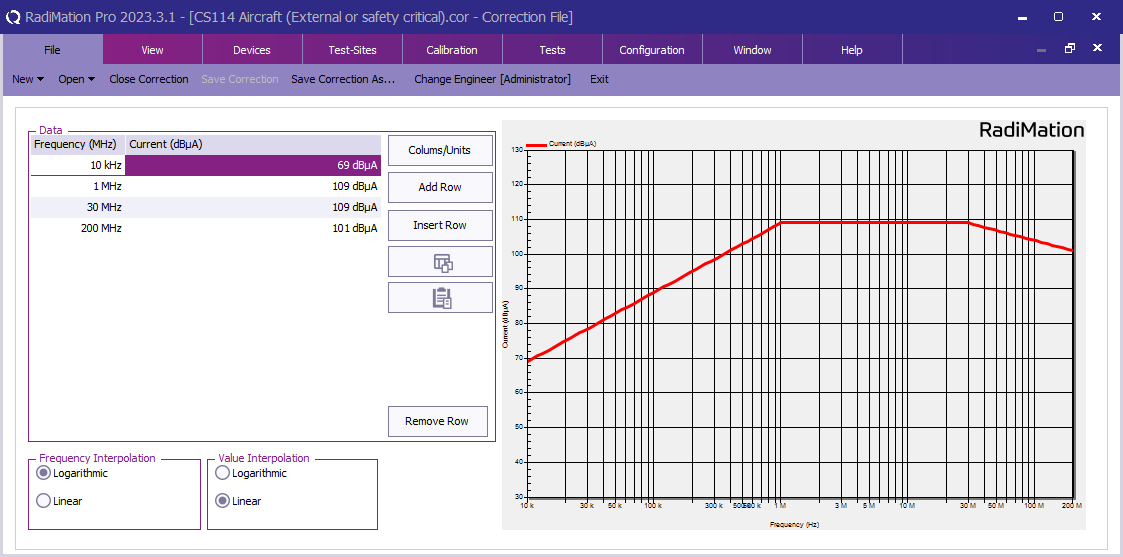

First create a correction file in {{RadiMation}} and specify the applicable test level (See 'TABLE IV CS114 limit curves.' and 'FIGURE CS114-1. CS114 calibration limits.'). | |||

In this example the limits for 'Aircraft (External or safety critical) / Curve 5 are configured. | |||

Ensure that the correction file has a {{ScreenElement|Frequency}} column and a {{ScreenElement|Current}} column with the unit set to dBuA. | |||

[[File:CS114_Test_level.png]] | |||

{{Menu|File|Save correction}} | |||

Store the test level as correction file on disk. | |||

This correction file with the test level will be used during the calibration, verification and the EUT testing. | |||

== Calibration procedure == | == Calibration procedure == | ||

| Line 84: | Line 71: | ||

|} | |} | ||

=== | === Configure the calibration === | ||

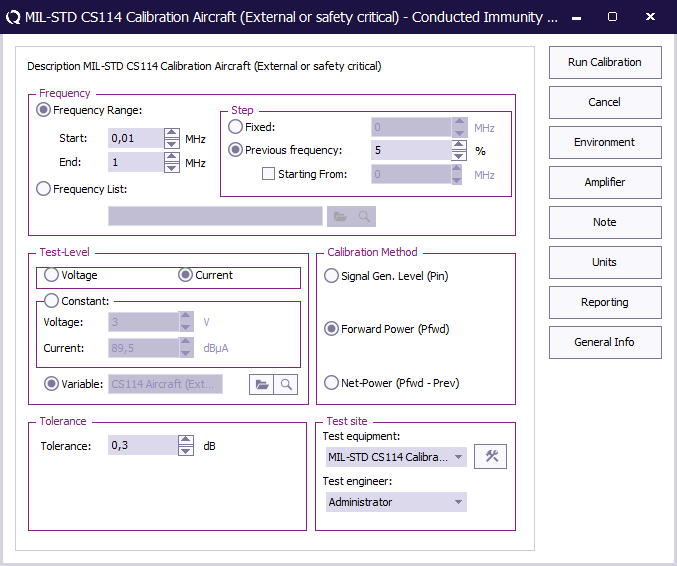

There are three frequency ranges that have to be calibrated with the following settings (see TABLE III). | There are three frequency ranges that have to be calibrated with the following settings (see TABLE III). | ||

{|class="wikitable" | {|class="wikitable" | ||

| Line 122: | Line 100: | ||

{{ScreenElementDescription|Test engineer|The engineer that performed the calibration.}} | {{ScreenElementDescription|Test engineer|The engineer that performed the calibration.}} | ||

{{ScreenElementDescriptionEnd}} | {{ScreenElementDescriptionEnd}} | ||

=== Calibration result === | === Calibration result === | ||

| Line 129: | Line 105: | ||

== Verification == | == Verification == | ||

=== | |||

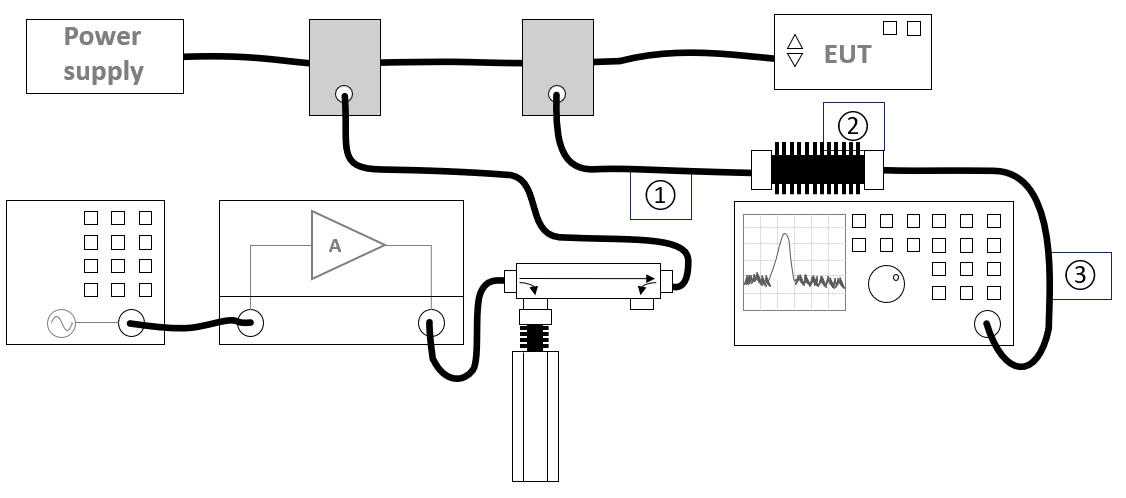

=== Verification equipment === | |||

[[File:CS114_Verification.png]] | |||

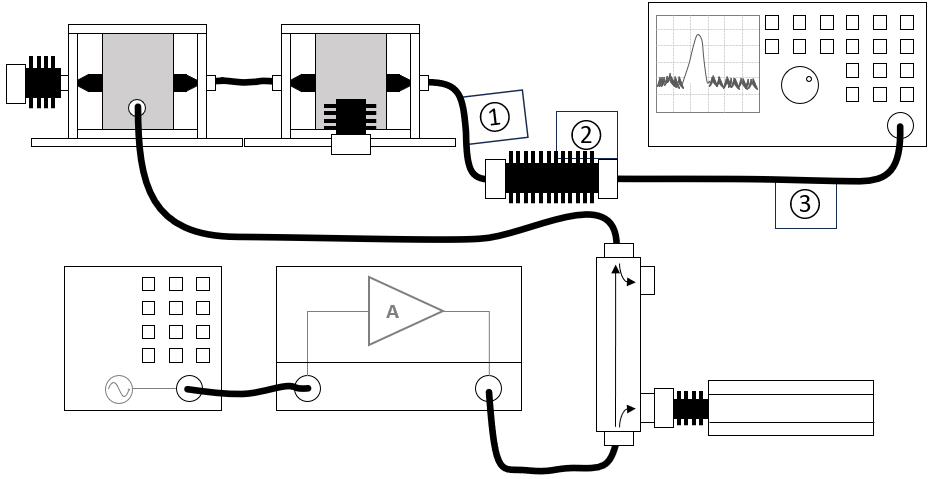

The configuration of the verification test site should contain the following devices: | |||

{|class="wikitable" | |||

!# || Device name || Tab in testsite configuration window || note | |||

|- | |||

| || Signal Generator || Devices 1 || The signal generator to use | |||

|- | |||

| || Amplifier || Devices 1 || The amplifier to use | |||

|- | |||

| || Coupler || Devices 1 || The coupler to use | |||

|- | |||

| || Forward power meter || Devices 1 || The forward power meter to use | |||

|- | |||

| || Sensor powermeter || Devices 2 || The power meter or analyser to use for measuring the current | |||

|- | |||

| || Current Sensor || Devices 2 || The current sensor to use with transfer factor attached to the driver | |||

|- | |||

| || Injection device || Devices 2 || The injection clamp to use | |||

|- | |||

!colspan="4"|Cables | |||

|- | |||

|① || Cable current -> power meter || Cables || Cable (1) with a correction file specified for the cable loss | |||

|- | |||

|② || Cable current -> power meter || Cables || Cable (2) with the specified loss of the used attenuator | |||

|- | |||

|③ || Cable current -> power meter || Cables || Cable (3) with a correction file specified for the cable loss | |||

|} | |||

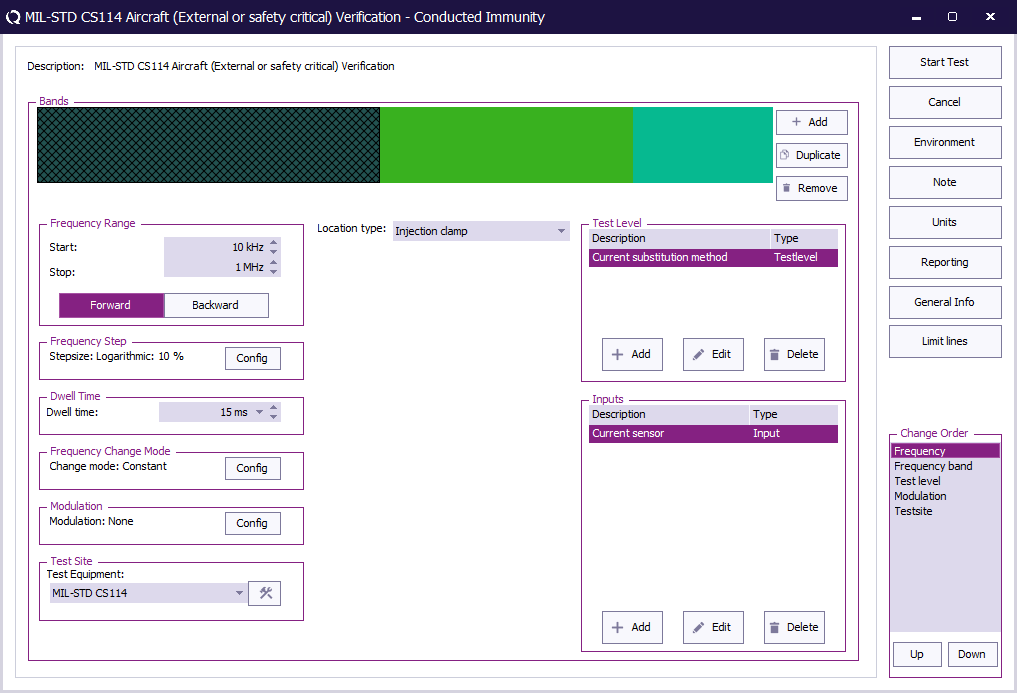

=== Configure the verification === | |||

CS114 requires to perform a verification of the setup with the probes in the calibration setup. With this verification it is important to verify that the forward power of the calibration is followed and that the generated current is within 3 dB tolerance of the current test limit. | CS114 requires to perform a verification of the setup with the probes in the calibration setup. With this verification it is important to verify that the forward power of the calibration is followed and that the generated current is within 3 dB tolerance of the current test limit. | ||

The verification can be performed in {{RadiMation}} by doing an actual conducted immunity test. This test can be started by selecting from the menu: | The verification can be performed in {{RadiMation}} by doing an actual conducted immunity test. This test can be started by selecting from the menu: | ||

| Line 145: | Line 152: | ||

|} | |} | ||

[[File:CS114 Verification Setup.png]] | [[File:CS114 Verification Setup.png]] | ||

{{ScreenElementDescriptionStart}} | {{ScreenElementDescriptionStart}} | ||

| Line 171: | Line 165: | ||

{{ScreenElementDescription|Inputs|Add the current sensor as an input.}} | {{ScreenElementDescription|Inputs|Add the current sensor as an input.}} | ||

{{ScreenElementDescriptionEnd}} | {{ScreenElementDescriptionEnd}} | ||

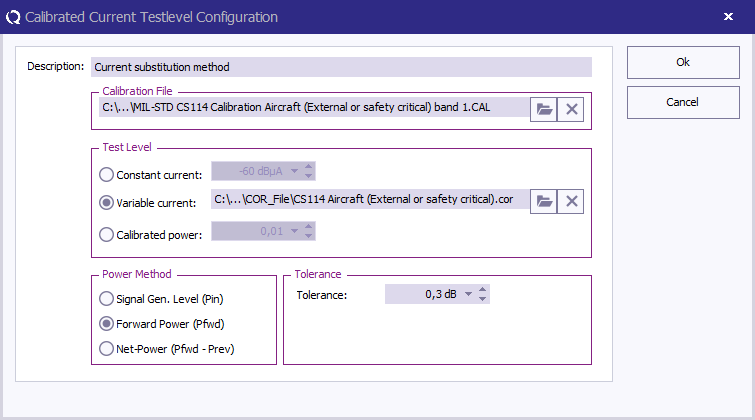

Each band needs a test level defined with the test level {{ScreenElement|Current substitution method}} and the appropriate calibration file attached. | |||

[[File:CS114 Current Testlevel Configuration.png]] | |||

{{ScreenElementDescriptionStart}} | |||

{{ScreenElementDescription|Description|The description of the test level.}} | |||

{{ScreenElementDescription|Calibration file|Select the calibration file to use.}} | |||

{{ScreenElementDescription|Test level|Variable current, and specify the correction file for the applicable test level.}} | |||

{{ScreenElementDescription|Calibration method|Select Forward Power.}} | |||

{{ScreenElementDescription|Tolerance|Specify the tolerance to use.}} | |||

{{ScreenElementDescriptionEnd}} | |||

Next to the test level add an input {{ScreenElement|Current sensor}}, this will ensure that the current is measured during the test. | |||

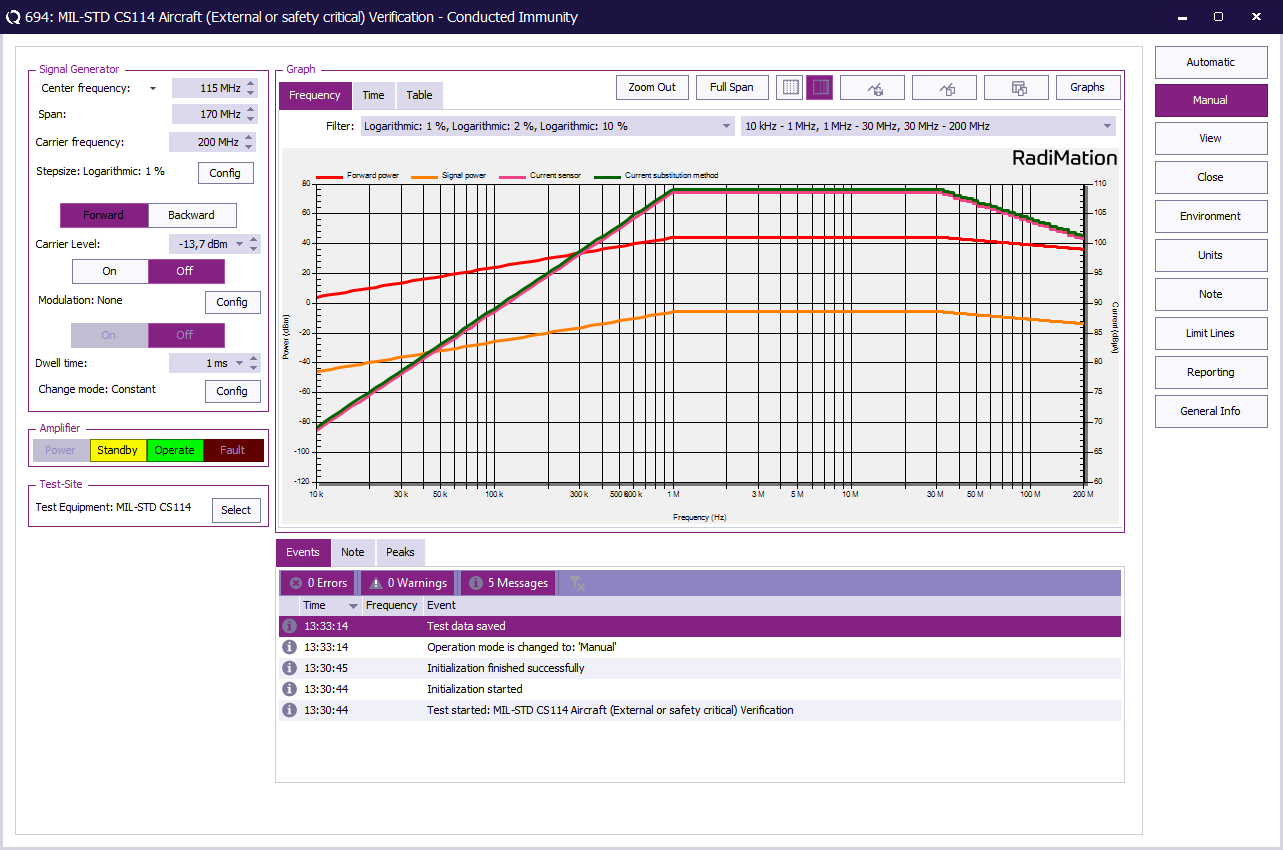

=== Run the verification test === | === Run the verification test === | ||

| Line 181: | Line 188: | ||

== EUT Testing == | == EUT Testing == | ||

=== | |||

=== EUT Testing equipment === | |||

[[File:CS114_EUT_Testing.png]] | |||

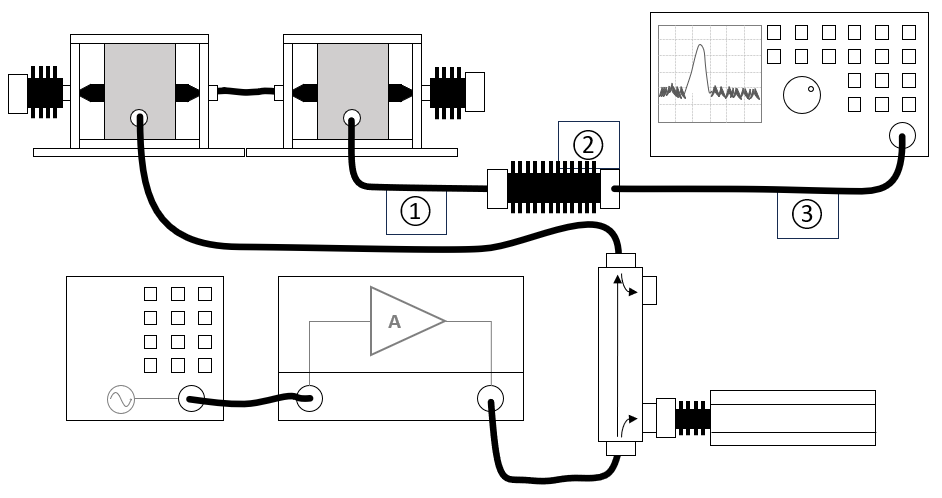

The configuration of the eut test site should contain the following devices: | |||

{|class="wikitable" | |||

!# || Device name || Tab in testsite configuration window || note | |||

|- | |||

| || Signal Generator || Devices 1 || The signal generator to use | |||

|- | |||

| || Amplifier || Devices 1 || The amplifier to use | |||

|- | |||

| || Coupler || Devices 1 || The coupler to use | |||

|- | |||

| || Forward power meter || Devices 1 || The forward power meter to use | |||

|- | |||

| || Sensor powermeter || Devices 2 || The power meter or analyser to use for measuring the current | |||

|- | |||

| || Current Sensor || Devices 2 || The current sensor to use with transfer factor attached to the driver | |||

|- | |||

| || Injection device || Devices 2 || The injection clamp to use | |||

|- | |||

!colspan="4"|Cables | |||

|- | |||

|① || Cable current -> power meter || Cables || Cable (1) with a correction file specified for the cable loss | |||

|- | |||

|② || Cable current -> power meter || Cables || Cable (2) with the specified loss of the used attenuator | |||

|- | |||

|③ || Cable current -> power meter || Cables || Cable (3) with a correction file specified for the cable loss | |||

|} | |||

=== Configure the EUT test === | |||

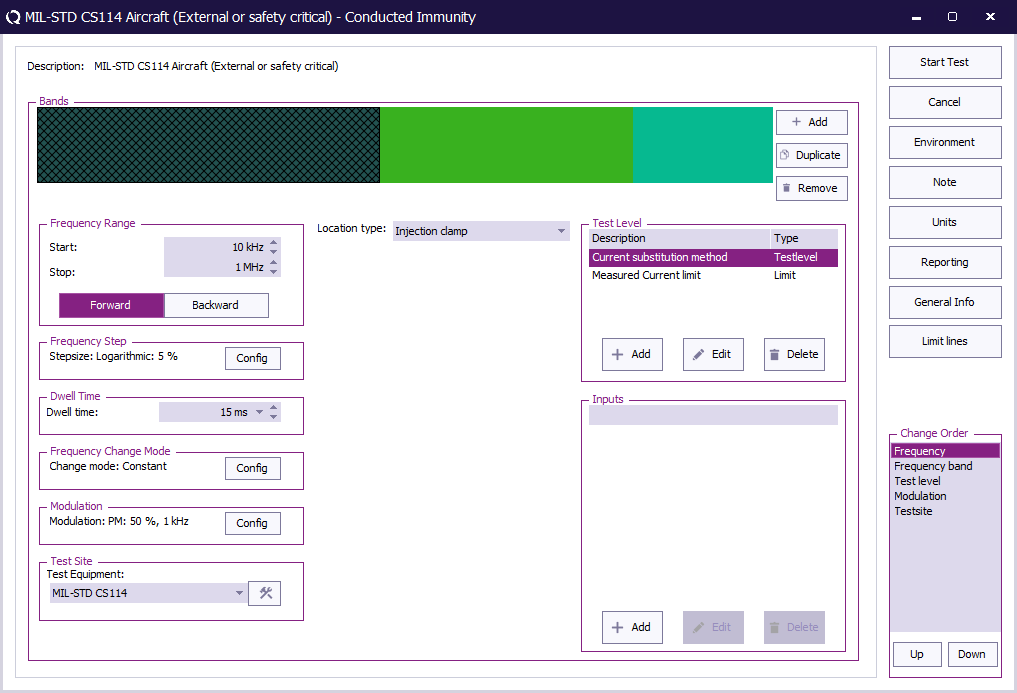

To perform the actual test on the EUT, create a conducted immunity multiband test with 3 bands. | To perform the actual test on the EUT, create a conducted immunity multiband test with 3 bands. | ||

The conducted immunity multiband test, can be started by selecting from the menu: | The conducted immunity multiband test, can be started by selecting from the menu: | ||

| Line 197: | Line 235: | ||

|} | |} | ||

[[File:CS114 Test Setup.png]] | [[File:CS114 Test Setup.png]] | ||

{{ScreenElementDescriptionStart}} | {{ScreenElementDescriptionStart}} | ||

| Line 218: | Line 255: | ||

{{ScreenElementDescription|Frequency|The PM frequency 1 kHz.}} | {{ScreenElementDescription|Frequency|The PM frequency 1 kHz.}} | ||

{{ScreenElementDescription|Duty Cycle|A duty cycle of 50%.}} | {{ScreenElementDescription|Duty Cycle|A duty cycle of 50%.}} | ||

{{ScreenElementDescription|Also apply modulation out of the dwell-time period|Check this checkbox to enable modulation outside the dwell-time.}} | |||

{{ScreenElementDescriptionEnd}} | {{ScreenElementDescriptionEnd}} | ||

Revision as of 09:53, 28 November 2023

How to perform a MIL-STD-461 CS114, Conducted susceptibility, bulk cable injection test[edit]

This application note explains how the MIL-STD-461 CS114, Conducted susceptibility, bulk cable injection test can be performed with RadiMation®

The exact requirements and test methods for the CS114 are specified in the MIL-STD-461.

Necessary equipment[edit]

The following devices are necessary to run the calibration, verification and EUT test:

- Signal generator

- Amplifier

- Coupler

- Forward power meter

- Current sensor

- Sensor power meter / Analyser

- 50 Ohm load

- 50 Ohm attenuator

- Current injection device

- Current injection calibration jig (Calibration fixture)

- Cable drivers with corrections

Tips[edit]

| Note: | If the current unit is shown as uA, it can be changed to dBuA by clicking Units, select Current and click Edit to change this. |

Define the test level[edit]

Create a correction file for the test level[edit]

-

File

File

-

New

New

-

Correction

Correction

-

-

-

First create a correction file in RadiMation® and specify the applicable test level (See 'TABLE IV CS114 limit curves.' and 'FIGURE CS114-1. CS114 calibration limits.'). In this example the limits for 'Aircraft (External or safety critical) / Curve 5 are configured.

Ensure that the correction file has a Frequency column and a Current column with the unit set to dBuA.

-

File

File

-

Save correction

Save correction

-

-

Store the test level as correction file on disk.

This correction file with the test level will be used during the calibration, verification and the EUT testing.

Calibration procedure[edit]

Calibration equipment[edit]

The configuration of the calibration test site should contain the following devices:

| # | Device name | Tab in testsite configuration window | note |

|---|---|---|---|

| Signal Generator | Devices 1 | The signal generator to use | |

| Amplifier | Devices 1 | The amplifier to use | |

| Coupler | Devices 1 | The coupler to use | |

| Forward power meter | Devices 1 | The forward power meter to use | |

| Sensor powermeter | Devices 2 | The power meter or analyser to use for measuring the current | |

| Current Sensor | Devices 2 | The current sensor to use with transfer factor attached to the driver | |

| Injection device | Devices 2 | The injection clamp to use | |

| Jig | Devices 2 | The jig to use | |

| Cables | |||

| ① | Cable current -> power meter | Cables | Cable (1) with a correction file specified for the cable loss |

| ② | Cable current -> power meter | Cables | Cable (2) with the specified loss of the used attenuator |

| ③ | Cable current -> power meter | Cables | Cable (3) with a correction file specified for the cable loss |

Configure the calibration[edit]

There are three frequency ranges that have to be calibrated with the following settings (see TABLE III).

| Band | Frequency range | Step size |

|---|---|---|

| Band 1 | 10 kHz - 1 MHz | 5 % |

| Band 2 | 1 MHz - 30 MHz | 1 % |

| Band 2 | 30 MHz - 200 MHz | 0.5 % |

These three bands can be configured and performed in three different calibrations. The calibration can be started from the menu by selecting:

-

Calibration

Calibration

-

System calibration

System calibration

-

Conducted immunity

Conducted immunity

-

-

-

This example shows the settings for band 1.

| The start frequency of the test. For example 10 kHz. |

| The stop frequency of the test. For example 1 MHz. |

| The frequency step, in this case 5%. |

| The test level, in this case current. |

| The variable test level, select the correction file created earlier. |

| The regulation tolerance. |

| Forward power. |

| Calibration test equipment. |

| The engineer that performed the calibration. |

Calibration result[edit]

When the calibration is performed, the engineer is asked, to save the results of that calibration to a calibration (.CAL) file. It is possible to give the .CAL file any clear and distinct name. All three bands have to calibrated, and at the end, there should be three different calibration files that are generated.

Verification[edit]

Verification equipment[edit]

The configuration of the verification test site should contain the following devices:

| # | Device name | Tab in testsite configuration window | note |

|---|---|---|---|

| Signal Generator | Devices 1 | The signal generator to use | |

| Amplifier | Devices 1 | The amplifier to use | |

| Coupler | Devices 1 | The coupler to use | |

| Forward power meter | Devices 1 | The forward power meter to use | |

| Sensor powermeter | Devices 2 | The power meter or analyser to use for measuring the current | |

| Current Sensor | Devices 2 | The current sensor to use with transfer factor attached to the driver | |

| Injection device | Devices 2 | The injection clamp to use | |

| Cables | |||

| ① | Cable current -> power meter | Cables | Cable (1) with a correction file specified for the cable loss |

| ② | Cable current -> power meter | Cables | Cable (2) with the specified loss of the used attenuator |

| ③ | Cable current -> power meter | Cables | Cable (3) with a correction file specified for the cable loss |

Configure the verification[edit]

CS114 requires to perform a verification of the setup with the probes in the calibration setup. With this verification it is important to verify that the forward power of the calibration is followed and that the generated current is within 3 dB tolerance of the current test limit. The verification can be performed in RadiMation® by doing an actual conducted immunity test. This test can be started by selecting from the menu:

-

Tests

Tests

-

Conducted Immunity

Conducted Immunity

-

Multiband

Multiband

-

-

-

Create a new multiband conducted immunity test and define three bands with the following settings:

| Band | Frequency range | Step size |

|---|---|---|

| Band 1 | 10 kHz - 1 MHz | 10 % |

| Band 2 | 1 MHz - 30 MHz | 2 % |

| Band 2 | 30 MHz - 200 MHz | 1 % |

| The start frequency of the test. For example 10 kHz. |

| The stop frequency of the test. For example 1 MHz. |

| The frequency step, see 5.12.3.4.c.3. |

| The dwell time specified see TABLE II. |

| Constant. |

| Modulation is optional during the verification. |

| The equipment needed for the verification. |

| Injection clamp. |

| Specify the current substitution method. |

| Add the current sensor as an input. |

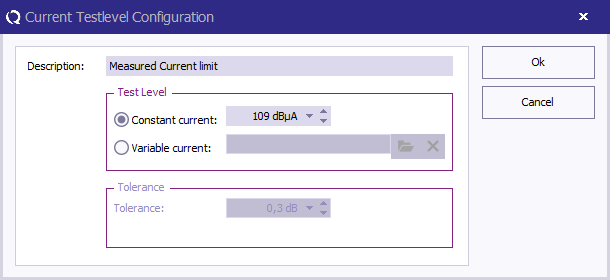

Each band needs a test level defined with the test level Current substitution method and the appropriate calibration file attached.

| The description of the test level. |

| Select the calibration file to use. |

| Variable current, and specify the correction file for the applicable test level. |

| Select Forward Power. |

| Specify the tolerance to use. |

Next to the test level add an input Current sensor, this will ensure that the current is measured during the test.

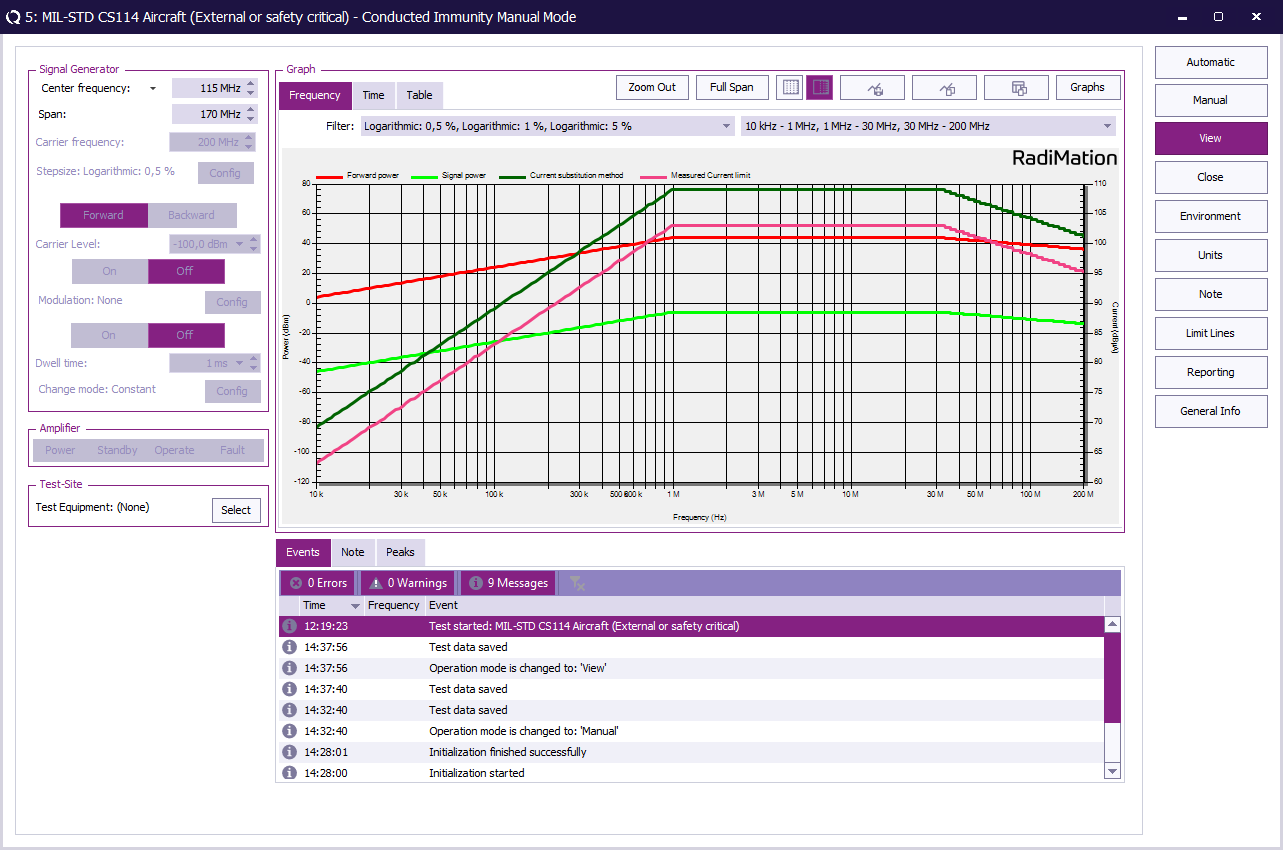

Run the verification test[edit]

When all settings are configured press Start Test to run the verification test.

Verification result[edit]

With the result of the verification it should be possible to determine if the measured current is within the 3 dB tolerance of the current test limit as specified in clause 5.12.3.4.c of the MIL-STD-461.

EUT Testing[edit]

EUT Testing equipment[edit]

The configuration of the eut test site should contain the following devices:

| # | Device name | Tab in testsite configuration window | note |

|---|---|---|---|

| Signal Generator | Devices 1 | The signal generator to use | |

| Amplifier | Devices 1 | The amplifier to use | |

| Coupler | Devices 1 | The coupler to use | |

| Forward power meter | Devices 1 | The forward power meter to use | |

| Sensor powermeter | Devices 2 | The power meter or analyser to use for measuring the current | |

| Current Sensor | Devices 2 | The current sensor to use with transfer factor attached to the driver | |

| Injection device | Devices 2 | The injection clamp to use | |

| Cables | |||

| ① | Cable current -> power meter | Cables | Cable (1) with a correction file specified for the cable loss |

| ② | Cable current -> power meter | Cables | Cable (2) with the specified loss of the used attenuator |

| ③ | Cable current -> power meter | Cables | Cable (3) with a correction file specified for the cable loss |

Configure the EUT test[edit]

To perform the actual test on the EUT, create a conducted immunity multiband test with 3 bands. The conducted immunity multiband test, can be started by selecting from the menu:

-

Tests

Tests

-

Conducted Immunity

Conducted Immunity

-

Multiband

Multiband

-

-

-

The following bands should be configured.

| Band | Frequency range | Step size |

|---|---|---|

| Band 1 | 10 kHz - 1 MHz | 5 % |

| Band 2 | 1 MHz - 30 MHz | 1 % |

| Band 2 | 30 MHz - 200 MHz | 0.5 % |

| The start frequency of the test. For example 10 kHz. |

| The stop frequency of the test. For example 1 MHz. |

| The frequency step, see Table III. |

| The dwell time. |

| Constant. |

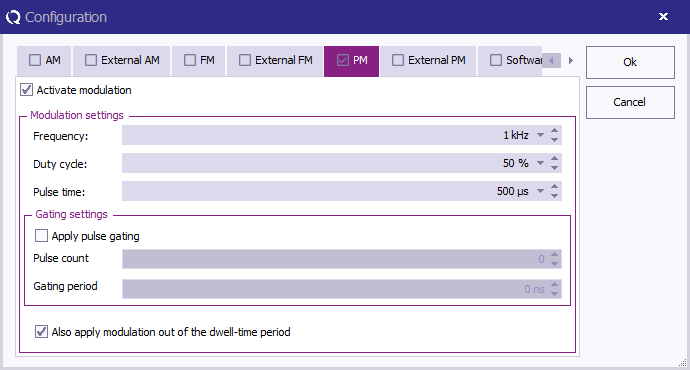

| Configure Pulse Modulation with 1 kHz and 50% duty cycle. |

| The equipment needed for the conducted immunity test. |

| Injection clamp. |

| Specify the current substitution method. Also add a "Measured Current Limit" |

| No inputs are needed. |

To configure the pulse modulation settings click Config next to the modulation settings, click the PM tab, and enter the pulse modulation settings as defined in 5.12.3.4.d.1.

| Check this checkbox to enable the pulse modulation. |

| The PM frequency 1 kHz. |

| A duty cycle of 50%. |

| Check this checkbox to enable modulation outside the dwell-time. |

At TestLevel click Add to add a new Test level and select TestLevel - Current substitution method

| The description of the test level. |

| Select the calibration file to use for this band. |

| Variable current, and specify the correction file for the applicable test level. |

| Select Forward Power. |

| Specify the tolerance to use. |

Next to the test level add a limit, At TestLevel click Add to add a new Limit and select Limit - Measured Current Limit

With this limit the level will not be regulated higher than the measured current in the cable even if the forward power is not reached yet.

| The description of the limit |

| The current to limit on. |

When all bands are configured press Start Test to run the EUT test.

EUT Test Result[edit]

Once the test is finished, the results of this test are stored in the EUT file and available as one of the performed Tests in the EUT file. Selecting the corresponding test result and pressing on Info will show the test results again.

Conclusion[edit]

The RadiMation® Conducted Immunity multiband test can be used to perform the CS114 verification and the EUT test with a calibration file and the current sensor used as a limit in the EUT test.