Chapter 10: Difference between revisions

m (Fix LED being pluralized with an apostrophe) |

|||

| (15 intermediate revisions by 3 users not shown) | |||

| Line 2: | Line 2: | ||

=EUT monitoring and control= | =EUT monitoring and control= | ||

== | ==Input Channels== | ||

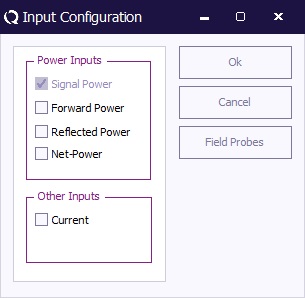

The input configuration is selected by pushing the | The input configuration is selected by pushing the {{ScreenElement|Input}} button in the [[TSF]] window of an immunity test. A window like the one shown below will appear. | ||

[[Image:Input Configuration Window.jpg]] | [[Image:Input Configuration Window.jpg]] | ||

| Line 10: | Line 10: | ||

===Goal=== | ===Goal=== | ||

The input channels of the | The input channels of the {{RadiMation}} software are implemented to monitor output signals of the [[EUT]] as a function of the test frequency. The software is able to monitor each channel before, during and after each test frequency. This way of data storage is useful during certification tests as well as during the development process of a product. | ||

The inputs channels allow automatic and accurate monitoring of EUT performance. Together with the output channels, full automatic tests can be performed without intervention of the test engineer. | The inputs channels allow automatic and accurate monitoring of EUT performance. Together with the output channels, full automatic tests can be performed without intervention of the test engineer. | ||

The | The {{ScreenElement|before field}} data of each input channel, tells you if the equipment is functioning properly before each test point. The {{ScreenElement|during field}} data of each input channel records if the equipment is influenced during period the test signal is applied. | ||

The | The {{ScreenElement|before field}} graph will record all instability and/or drift of the EUT, where the {{ScreenElement|during field}} graph will record both the instability and/or drift of the EUT and any influence of the EUT by the RF field. | ||

The Software is able to support a maximum of 8 A/D converters | The Software is able to support a maximum of 8 A/D converters. For each A/D channel, two graphs can be recorded ('before field' and 'during field' graph). As an alternative, {{RadiMation}} can also read data from oscilloscopes, audio analysers etc and use it as an A/D input signal. In this case, the operator should select the device driver for the measurement device (for example the oscilloscope) under A/D converter device driver in the equipment list. | ||

The analogue channels can be used to monitor analogue voltages, currents, temperature, tacho generators etc. With some extra tools like opto couplers | The analogue channels can be used to monitor analogue voltages, currents, temperature, tacho generators etc. With some extra tools like opto couplers LEDs of the EUT can be monitored. | ||

Apart from the AD converters, | Apart from the AD converters, 'Field sensors', 'forward power', 'reflected power' and 'current probes' can be used as input. | ||

=== | === EUT Monitoring Configuration=== | ||

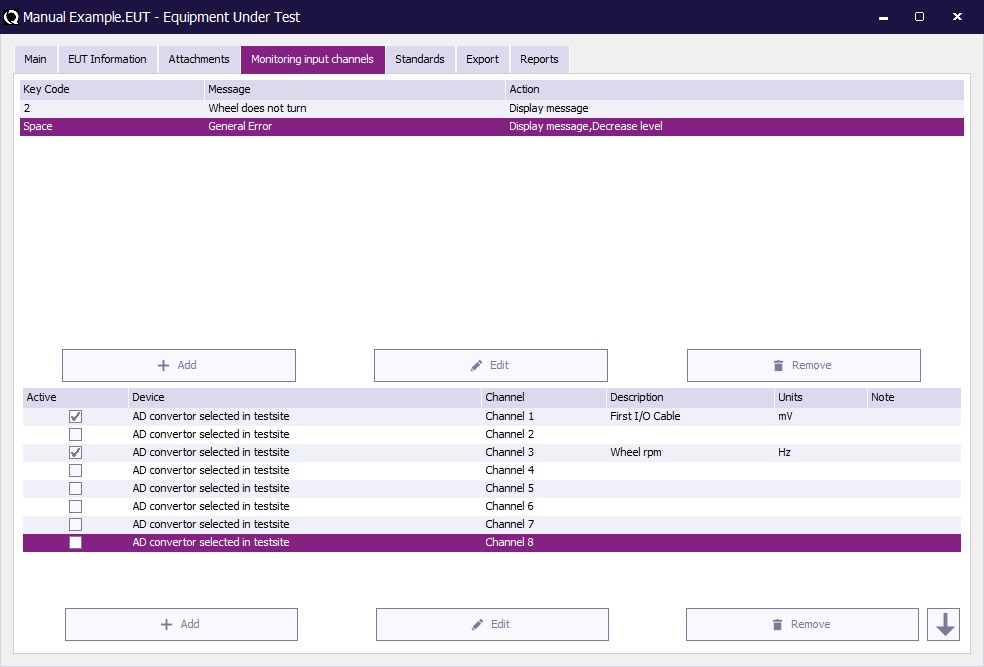

The monitoring functionality for a specific EUT is configured in the EUT itself, because it is specific to that EUT. | |||

In the opened EUT file, all the monitored channels are available on the {{ScreenElement|Monitoring input channels}} tab. Double click an existing input channel opens the configuration of that channel or a new monitoring input channel can be added by using the {{ScreenElement|Add}} button. | |||

[[Image:EUT AD Channels Tab.jpg]] | [[Image:EUT AD Channels Tab.jpg]] | ||

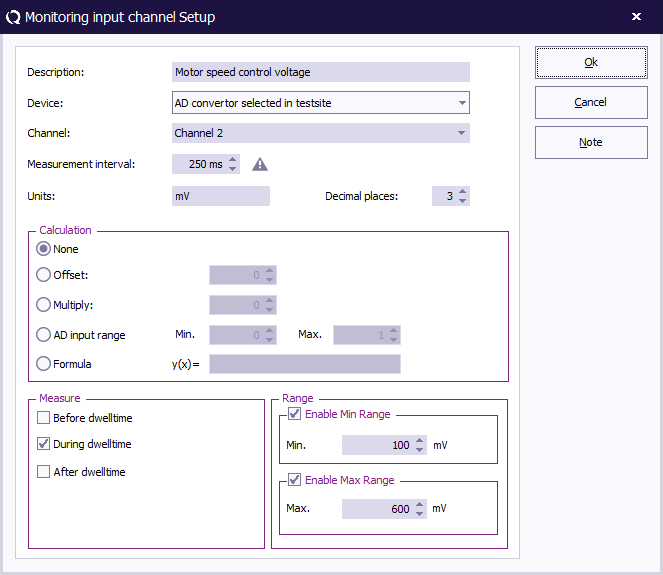

In the configuration window of a specific input, the monitoring input channel can be configured. | |||

[[Image:Monitoring input channel setup.png]] | |||

{{ScreenElementDescription| | {{ScreenElementDescriptionStart}} | ||

{{ScreenElementDescription|Description|Can be any text that identifies this channel. This description will also be used as the graphline in the final test.}} | |||

{{ScreenElementDescription| | {{ScreenElementDescription|Device|The device driver that should be used to perform the measurement of the value. If the {{ScreenElement|AD convertor selected in testsite}} is selected, the device that is selected as the {{ScreenElement|AD Convertor}} in the testsite that is selected in the TSF of the test will be used.}} | ||

{{ScreenElementDescription|Channel|The channel of the selected device driver that should be measured.}} | |||

{{ | {{ScreenElementDescription|Measurement interval|For pulsed immunity tests, a measurement interval can be specified, as a suggestion for the time interval between two sequential measurements of this same channel. The value should be in the range between 1 milliseconds and 60 seconds, and the default value is 250 milliseconds. This measurement interval is not used for radiated and conducted immunity tests, and then not relevant.}} | ||

{{ScreenElementDescription|Units|The unit that should be used for the representation of the measured value. The specified unit is only used as a label in the corresponding graph.}} | |||

{{ScreenElementDescription|Decimal places|The number of decimal places that should be used to represent the measured values, when the values are shown as a numerical value, for example in a table. If the value should be shown with a 0.01 resolution, the {{ScreenElement|Decimal places}} can be set to 2.}} | |||

{{ScreenElementDescription|Calculation|The measured value can be recalculated to another value. {{ScreenElementDescriptionStart}} | |||

{{ScreenElementDescription|None|No calculation on the retrieved value is done. The retrieved value is directly passed as the final value of the monitoring input.}} | |||

{{ScreenElementDescription|Offset|The value specified for the {{ScreenElement|Offset}} will be added to the retrieved value. {{ScreenElement|Offset}} can be a positive or negative number. The result of the addition will be the final value of the monitoring input.}} | |||

{{ScreenElementDescription|Multiply|The value specified for the {{ScreenElement|Multiply}} will be used to multiply the retrieved value. {{ScreenElement|Multiply}} can be a positive or negative number. The result of the multiplication will be the final value of the monitoring input.}} | |||

{{ScreenElementDescription|AD input range|The values specified for the {{ScreenElement|Min}} and {{ScreenElement|Max}} values are used to perform a re-mapping of the minimum and maximum value of the AD convertor device driver. If for example a multimeter is used which is able to measure the voltage between 0 and 100 V, but it is connected to a 0.5 {{Ohm}} shunt resistor, to measure the current, the {{ScreenElement|Min}} can be set to 0 A, and the {{ScreenElement|Max}} can be set to 200 A.}} | |||

{{ScreenElementDescription|Formula|The text specified for the {{ScreenElement|Formula}} is used to recalculate 'x' into a final value of the monitoring input. Standard operations like, *, /, +, -, ( and ) can be combined with values to perform a more complex recalculation of the retrieved value.}} | |||

{{ScreenElementDescriptionEnd}} }} | |||

{{ScreenElementDescription|Measure|The selected options in the {{ScreenElement|Measure}} group, determine at which moment the monitoring input will be measured. One or more of these options can be selected. {{ScreenElementDescriptionStart}} | |||

{{ScreenElementDescription|Before dwelltime|The monitoring input will be measured after the testlevel has been regulated, just before the modulation is activated and the dwelltime is started.}} | |||

{{ScreenElementDescription|During dwelltime|The monitoring input will be measured while the modulation is still being applied at the end of the dwelltime just before the dwelltime will finish. This is the best selection, as the value that is measured just before the end of the dwelltime is the most interesting point to determine if the EUT is being influenced.}} | |||

{{ScreenElementDescription|After dwelltime|The monitoring input will be measured directly after the dwelltime has passed, and the modulation has been deactivated again.}} | |||

{{ScreenElementDescriptionEnd}} }} | |||

{{ScreenElementDescription|Range|A range of allowed values can be specified for this measurement. The {{ScreenElement|Min Range}} can be set to specify the minimum allowed valid value of the measurement. The {{ScreenElement|Max Range}} can be set to specify the maximum allowed valid value of the measurement. If at any moment the measured value is out of this accepted allowed range, it is assumed that the EUT is being influenced.}} | |||

{{ScreenElementDescription|Note|Any additional information or documentation can be added to the monitoring input, by specifying it in the note. This information can be used to describe test conditions or the response of the EUT during the tests. The information can also be changed after the test is completed in the test information screen.}} | |||

{{ScreenElementDescriptionEnd}} | |||

===Field sensors=== | ===Field sensors=== | ||

| Line 63: | Line 61: | ||

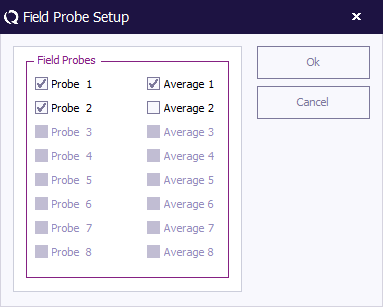

During a substitution test, a field sensor can be used to record the field strength near the EUT and record it in a graph. It should be noted that the presence of the EUT in the chamber will influence the field homogeneity in the close vicinity of the EUT. Therefore, the field sensor will probably not give the same reading as it would give in an empty chamber. The field sensor reading should therefore only be used as an indication. | During a substitution test, a field sensor can be used to record the field strength near the EUT and record it in a graph. It should be noted that the presence of the EUT in the chamber will influence the field homogeneity in the close vicinity of the EUT. Therefore, the field sensor will probably not give the same reading as it would give in an empty chamber. The field sensor reading should therefore only be used as an indication. | ||

[[Image:Field Probe Setup Configuration Window.png]] | |||

===Current probes=== | ===Current probes=== | ||

| Line 70: | Line 69: | ||

Product improvements on an EUT therefore are more easily performed with a current injection set-up | Product improvements on an EUT therefore are more easily performed with a current injection set-up | ||

. | . | ||

For this purpose, during a substitution test, a current sensor can be used to record the RF current in one of the I/O cables of the EUT. | For this purpose, during a substitution test, a current sensor can be used to record the RF current in one of the I/O cables of the EUT. {{RadiMation}} can record the injected current in this cable due to the applied field. | ||

| Line 76: | Line 75: | ||

To get accurate current values, the current probe should be connected through a fibre optic cable in stead of using a coaxial cable. A coax cable will cause common-mode currents to flow on the screen, resulting in inaccurate test results. | To get accurate current values, the current probe should be connected through a fibre optic cable in stead of using a coaxial cable. A coax cable will cause common-mode currents to flow on the screen, resulting in inaccurate test results. | ||

[[Category:Manual]] | |||

Latest revision as of 09:51, 5 February 2025

EUT monitoring and control[edit]

Input Channels[edit]

The input configuration is selected by pushing the Input button in the TSF window of an immunity test. A window like the one shown below will appear.

Goal[edit]

The input channels of the RadiMation® software are implemented to monitor output signals of the EUT as a function of the test frequency. The software is able to monitor each channel before, during and after each test frequency. This way of data storage is useful during certification tests as well as during the development process of a product.

The inputs channels allow automatic and accurate monitoring of EUT performance. Together with the output channels, full automatic tests can be performed without intervention of the test engineer.

The before field data of each input channel, tells you if the equipment is functioning properly before each test point. The during field data of each input channel records if the equipment is influenced during period the test signal is applied.

The before field graph will record all instability and/or drift of the EUT, where the during field graph will record both the instability and/or drift of the EUT and any influence of the EUT by the RF field.

The Software is able to support a maximum of 8 A/D converters. For each A/D channel, two graphs can be recorded ('before field' and 'during field' graph). As an alternative, RadiMation® can also read data from oscilloscopes, audio analysers etc and use it as an A/D input signal. In this case, the operator should select the device driver for the measurement device (for example the oscilloscope) under A/D converter device driver in the equipment list.

The analogue channels can be used to monitor analogue voltages, currents, temperature, tacho generators etc. With some extra tools like opto couplers LEDs of the EUT can be monitored. Apart from the AD converters, 'Field sensors', 'forward power', 'reflected power' and 'current probes' can be used as input.

EUT Monitoring Configuration[edit]

The monitoring functionality for a specific EUT is configured in the EUT itself, because it is specific to that EUT.

In the opened EUT file, all the monitored channels are available on the Monitoring input channels tab. Double click an existing input channel opens the configuration of that channel or a new monitoring input channel can be added by using the Add button.

In the configuration window of a specific input, the monitoring input channel can be configured.

| Can be any text that identifies this channel. This description will also be used as the graphline in the final test. |

| The device driver that should be used to perform the measurement of the value. If the AD convertor selected in testsite is selected, the device that is selected as the AD Convertor in the testsite that is selected in the TSF of the test will be used. |

| The channel of the selected device driver that should be measured. |

| For pulsed immunity tests, a measurement interval can be specified, as a suggestion for the time interval between two sequential measurements of this same channel. The value should be in the range between 1 milliseconds and 60 seconds, and the default value is 250 milliseconds. This measurement interval is not used for radiated and conducted immunity tests, and then not relevant. |

| The unit that should be used for the representation of the measured value. The specified unit is only used as a label in the corresponding graph. |

| The number of decimal places that should be used to represent the measured values, when the values are shown as a numerical value, for example in a table. If the value should be shown with a 0.01 resolution, the Decimal places can be set to 2. |

The measured value can be recalculated to another value.

|

The selected options in the Measure group, determine at which moment the monitoring input will be measured. One or more of these options can be selected.

|

| A range of allowed values can be specified for this measurement. The Min Range can be set to specify the minimum allowed valid value of the measurement. The Max Range can be set to specify the maximum allowed valid value of the measurement. If at any moment the measured value is out of this accepted allowed range, it is assumed that the EUT is being influenced. |

| Any additional information or documentation can be added to the monitoring input, by specifying it in the note. This information can be used to describe test conditions or the response of the EUT during the tests. The information can also be changed after the test is completed in the test information screen. |

Field sensors[edit]

During a substitution test, a field sensor can be used to record the field strength near the EUT and record it in a graph. It should be noted that the presence of the EUT in the chamber will influence the field homogeneity in the close vicinity of the EUT. Therefore, the field sensor will probably not give the same reading as it would give in an empty chamber. The field sensor reading should therefore only be used as an indication.

Current probes[edit]

Current injection tests are more easily carried out and are less expensive than tests in an anechoic chamber (caused by the very expensive test equipment needed for radiated immunity tests).

Product improvements on an EUT therefore are more easily performed with a current injection set-up . For this purpose, during a substitution test, a current sensor can be used to record the RF current in one of the I/O cables of the EUT. RadiMation® can record the injected current in this cable due to the applied field.

This current sensor data can be used to simulate the influence to the EUT, in a current injection test set-up.

To get accurate current values, the current probe should be connected through a fibre optic cable in stead of using a coaxial cable. A coax cable will cause common-mode currents to flow on the screen, resulting in inaccurate test results.