RadiMation Application Note 148: Difference between revisions

(Created page with "__NOTOC__ == How to perform a MIL-STD CE101, Conducted Emissions, audio frequency currents, power leads test == This application note explains how the MIL-STD RE101, Conducted...") |

|||

| Line 1: | Line 1: | ||

__NOTOC__ | __NOTOC__ | ||

== How to perform a MIL-STD CE101, Conducted Emissions, audio frequency currents, power leads test == | == How to perform a MIL-STD CE101, Conducted Emissions, audio frequency currents, power leads test == | ||

This application note explains how the MIL-STD | This application note explains how the MIL-STD CE101, Conducted Emissions, audio frequency currents, power leads test can be performed with {{RadiMation}}. | ||

The exact requirements and test methods for the CE101 are specified in the [[MIL-STD-461]]. | The exact requirements and test methods for the CE101 are specified in the [[MIL-STD-461]]. | ||

Revision as of 13:00, 22 May 2023

How to perform a MIL-STD CE101, Conducted Emissions, audio frequency currents, power leads test[edit]

This application note explains how the MIL-STD CE101, Conducted Emissions, audio frequency currents, power leads test can be performed with RadiMation®.

The exact requirements and test methods for the CE101 are specified in the MIL-STD-461.

Necessary equipment[edit]

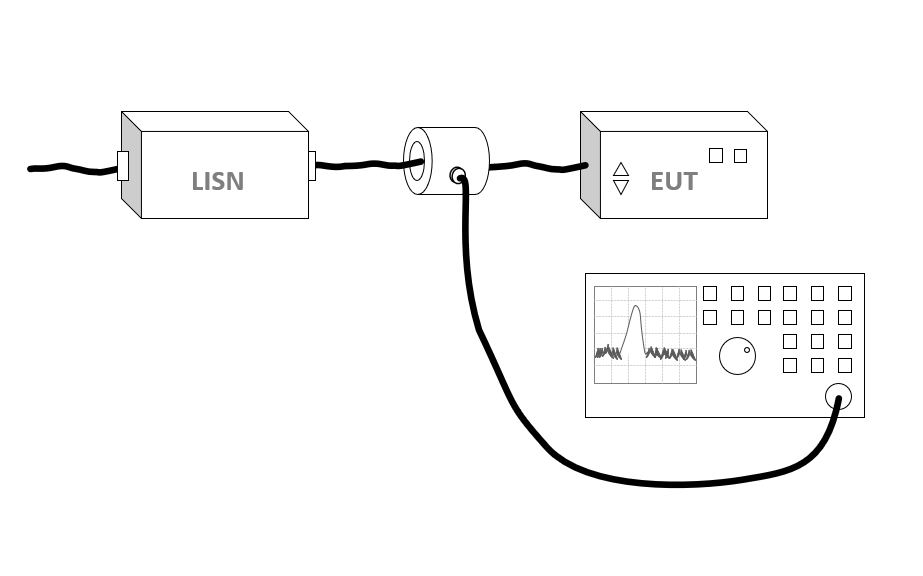

The following devices are necessary to execute this test:

- Receiver

- Current sensor

- LISN

- Cable

Configuration of the testsites[edit]

The configuration of the equipment is a current sensor connected with a cable to a receiver.

The configuration of the test site should contain the following devices:

| Device name | Tab in testsite configuration window | note |

|---|---|---|

| Current sensor | Devices 2 | Current sensor |

| Spectrum Analyser | Devices 2 | The receiver used for the test |

| Cable preamp -> analyser | Cables | Cable with a correction file specified for the loss |

Note the lisn is only used to decouple and it is not needed to specify and configure this in RadiMation®

Configuration of the Current sensor[edit]

The current sensor needs to have the correction data applied which is normally known by the manufacturer or provided by a calibration company. The correction data is often expressed in Ohm (Resistance).

In RadiMation® this can be configured by creating a correction file, which contains a 'Frequency' and a 'Correction' column. Then specify the frequencies and the correction values in the correction file. The correction values are expressed in Ohm.

It is also possible to specify the values in dBOhm, in that case the Correction column needs to be removed and then a new column should be added of type 'Resistance' with the unit dBOhm.

After creating a correction file and saving it to disk it is now important to select this correction file in the Current Sensor device driver.

Perform the test[edit]

To perform the actual CE101 test, start a Conducted Emission Multiband test:

-

Tests

Tests

-

Conducted Emission

Conducted Emission

-

Multiband

Multiband

-

-

-

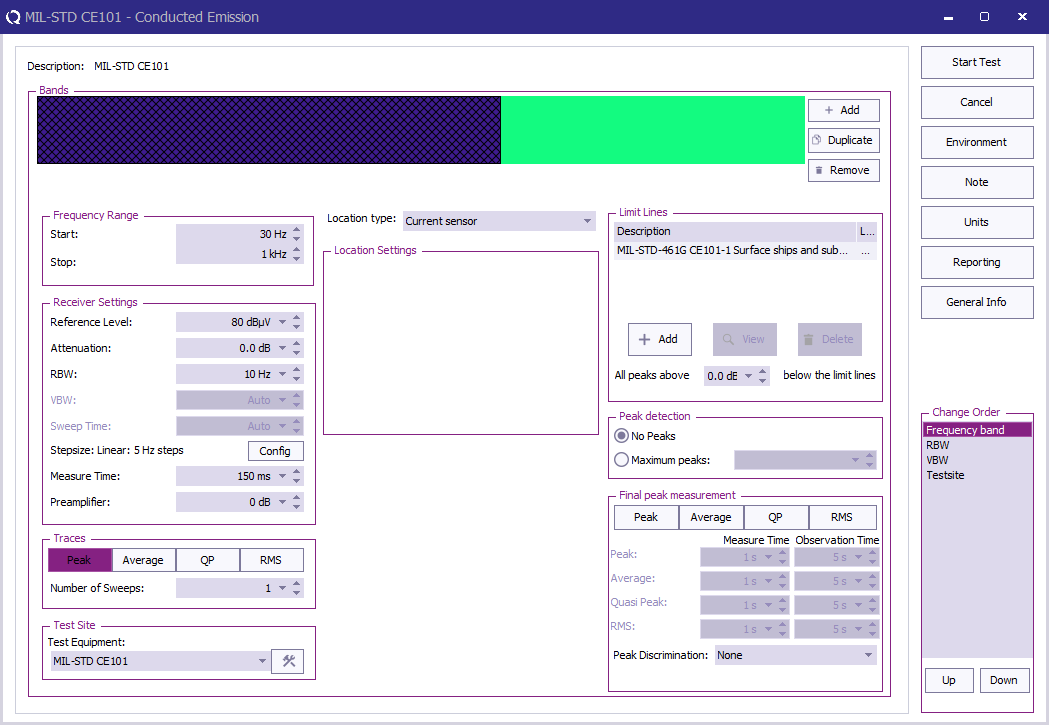

The complete test from 30 Hz up to 10 kHz has different settings for different frequency bands. All these different bands can be configured. The test can be configured with 2 bands, each using their applicable frequency range, measure time and bandwidth.

| Band | Frequency range | RBW | Step size | Measure time receiver | Measure time FFT receiver |

|---|---|---|---|---|---|

| Band 1 | 30 Hz - 1 kHz | 10 Hz | 5 Hz | 0.15 s | 1 s |

| Band 2 | 1 kHz - 10 kHz | 100 Hz | 50 Hz | 0.015 s | 1 s |

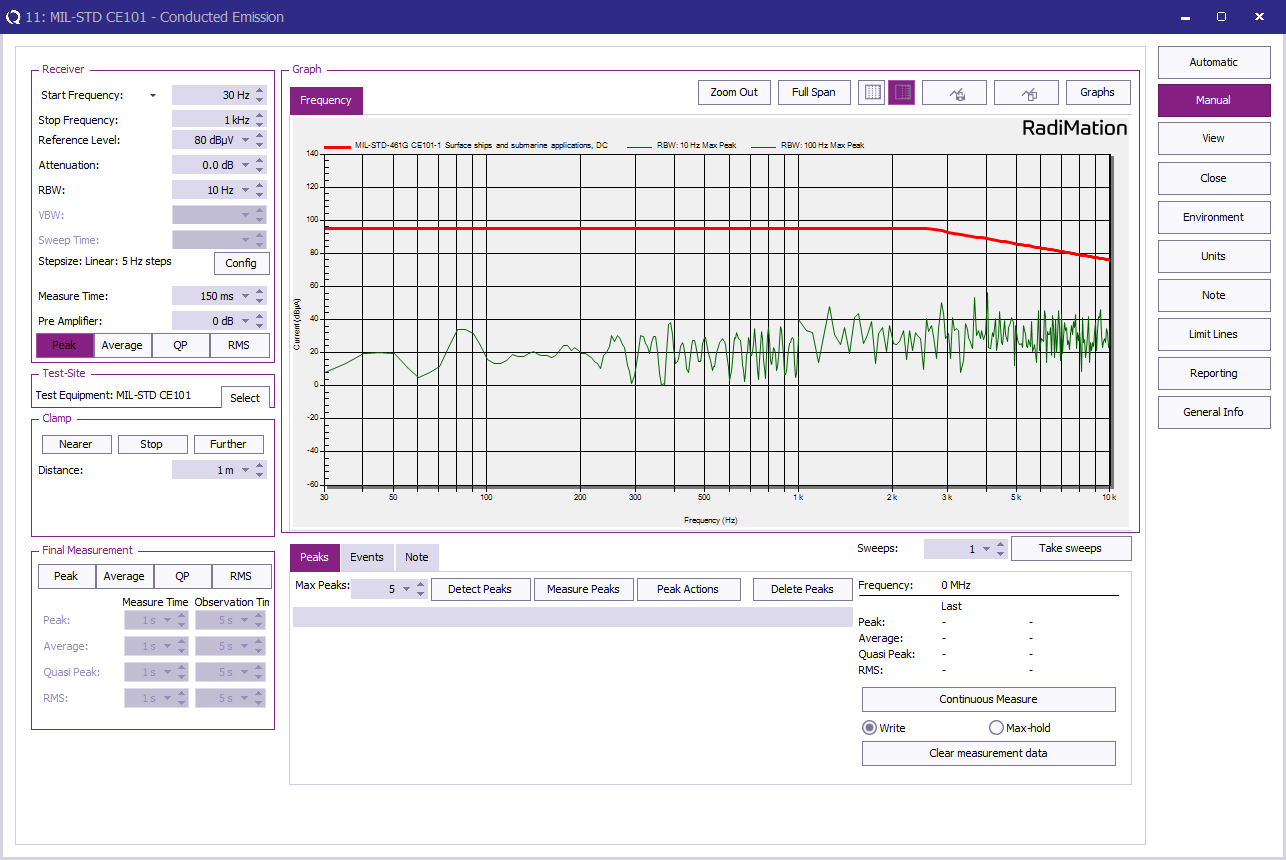

In the following test configuration an EUT for "Surface ships and submarine applications, DC" is tested.

| The start frequency of the test. For example 30 Hz. |

| The stop frequency of the test. For example 10 kHz. |

| The reference level set in an analyser, not used in a receiver |

| The attenuation set in the receiver |

| The RBW set in the receiver, see table with different bands for possible values |

| The step size set in the receiver, see table with different bands for possible values |

| The measure time set in the receiver, see table with different bands for possible values |

| The preamplifier setting set in the receiver |

| The type of trace set in the receiver, for MIL-STD CE101 a peak detector is used |

| The equipment used for the measurement, see table with different bands for possible values |

| Set this to "Current sensor" |

| The applicable limit line can be added, in this case "MIL-STD-461G CE101-1 Surface ships and submarine applications, DC" |

| Which level above x dB below the limit line should detect peaks, no final peaks should be measured in MIL-STD CE101 |

| How many peaks should be detected automatically, no final peaks should be measured for MIL-STD RE101 |

| It is possible to perform a final measurement on a peak with a specific detector, no final peak measurement is needed for CE101 |

When all parameters are configured for the CE101 test, press Start Test to perform the conducted emission measurement.

Review the measurement[edit]

Once the test is finished, the results of this test are stored in the EUT file and available as one of the performed Tests in the EUT file. Selecting the corresponding test result and pressing on Info will show the test results again.

Conclusion[edit]

The MIL-STD CE101 test is using different receiver settings depending on the frequency band. All these settings can be easily configured in a "Test Setup File" and tested with RadiMation®.