RadiMation Application Note 154: Difference between revisions

| Line 115: | Line 115: | ||

== Calibration procedure == | == Calibration procedure == | ||

=== Create correction file for the test level === | |||

{{Menu|File|New|Correction}} | |||

First create a correction file in {{RadiMation}} and specify the applicable test level (See 'TABLE IV CS114 limit curves.' and 'FIGURE CS114-1. CS114 calibration limits.'). | First create a correction file in {{RadiMation}} and specify the applicable test level (See 'TABLE IV CS114 limit curves.' and 'FIGURE CS114-1. CS114 calibration limits.'). | ||

In this example the limits for 'Aircraft (External or safety critcal) / Curve 5 are configured. | In this example the limits for 'Aircraft (External or safety critcal) / Curve 5 are configured. | ||

Make sure to remove the Correction column and add the current column with the unit set to dBuV. | |||

[[File:CS114_Test_level.png]] | [[File:CS114_Test_level.png]] | ||

=== Create calibration test setup file === | |||

{{Menu|Calibration|System calibration|Conducted immunity}} | |||

== Verification == | == Verification == | ||

Revision as of 15:09, 16 October 2023

How to perform a MIL-STD CS114, Conducted susceptibility, bulk cable injection test[edit]

This application note explains how the MIL-STD CS114, Conducted susceptibility, bulk cable injection test can be performed with RadiMation®

The exact requirements and test methods for the CS114 are specified in the MIL-STD-461.

Necessary equipment[edit]

The following devices are necessary to execute this test:

- Signal generator

- Amplifier

- Coupler

- Forward power meter

- Reflected power meter (optionally)

- Current sensor

- Sensor power meter / Analyser

- 50 Ohm load

- 50 Ohm attenuator

- LISN

- Current injection device

- Current injection calibration jig (Calibration fixture)

- Cable drivers with corrections

Configuration of the test sites[edit]

Calibration[edit]

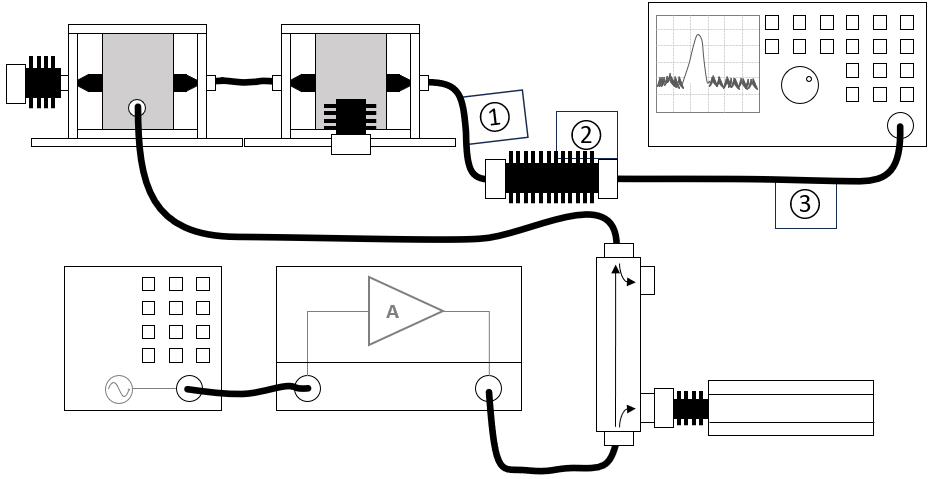

The configuration of the calibration test site should contain the following devices:

| Device name | Tab in testsite configuration window | note |

|---|---|---|

| Signal generator | Devices 1 | The signal generator to use |

| Amplifier | Devices 1 | The amplifier to use |

| Coupler | Devices 1 | The coupler to use |

| Forward power meter | Devices 1 | The forward power meter to use |

| Reflected power meter | Devices 1 | The reflected power meter to use (optionally) |

| Sensor power meter | Devices 2 | The power meter or analyser to use for measuring the current |

| Current sensor | Devices 2 | The current sensor to use with transfer factor attached to the driver |

| Injection device | Devices 2 | The injection clamp to use |

| Jig | Devices 2 | The jig to use |

| Cable current -> power meter | Cables | Cable (1) with a correction file specified for the cable loss |

| Cable current -> power meter | Cables | Cable (2) with the specified loss of the used attenuator |

| Cable current -> power meter | Cables | Cable (3) with a correction file specified for the cable loss |

Verification[edit]

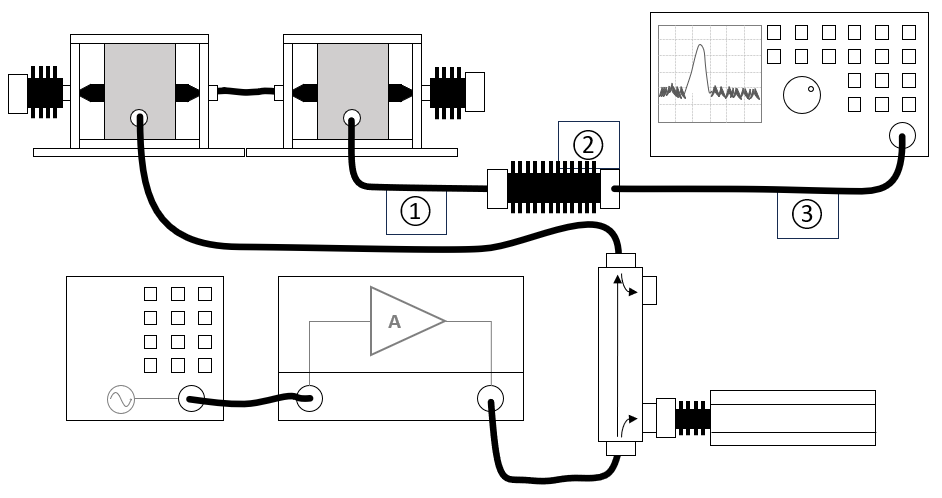

The configuration of the verification test site should contain the following devices:

| Device name | Tab in testsite configuration window | note |

|---|---|---|

| Signal generator | Devices 1 | The signal generator to use |

| Amplifier | Devices 1 | The amplifier to use |

| Coupler | Devices 1 | The coupler to use |

| Forward power meter | Devices 1 | The forward power meter to use |

| Reflected power meter | Devices 1 | The reflected power meter to use (optionally) |

| Sensor power meter | Devices 2 | The power meter or analyser to use for measuring the current |

| Current sensor | Devices 2 | The current sensor to use with transfer factor attached to the driver |

| Injection device | Devices 2 | The injection clamp to use |

| Cable current -> power meter | Cables | Cable (1) with a correction file specified for the cable loss |

| Cable current -> power meter | Cables | Cable (2) with the specified loss of the used attenuator |

| Cable current -> power meter | Cables | Cable (3) with a correction file specified for the cable loss |

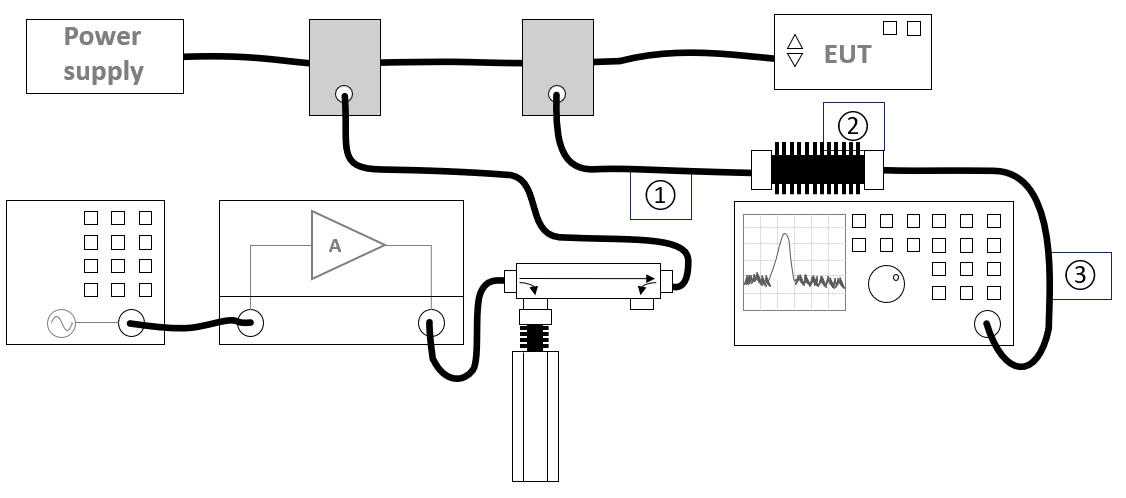

EUT Testing[edit]

The configuration of the eut test site should contain the following devices:

| Device name | Tab in testsite configuration window | note |

|---|---|---|

| Signal generator | Devices 1 | The signal generator to use |

| Amplifier | Devices 1 | The amplifier to use |

| Coupler | Devices 1 | The coupler to use |

| Forward power meter | Devices 1 | The forward power meter to use |

| Reflected power meter | Devices 1 | The reflected power meter to use (optionally) |

| Sensor power meter | Devices 2 | The power meter or analyser to use for measuring the current |

| Current sensor | Devices 2 | The current sensor to use with transfer factor attached to the driver |

| Injection device | Devices 2 | The injection clamp to use |

| Cable current -> power meter | Cables | Cable (1) with a correction file specified for the cable loss |

| Cable current -> power meter | Cables | Cable (2) with the specified loss of the used attenuator |

| Cable current -> power meter | Cables | Cable (3) with a correction file specified for the cable loss |

Calibration procedure[edit]

Create correction file for the test level[edit]

-

File

File

-

New

New

-

Correction

Correction

-

-

-

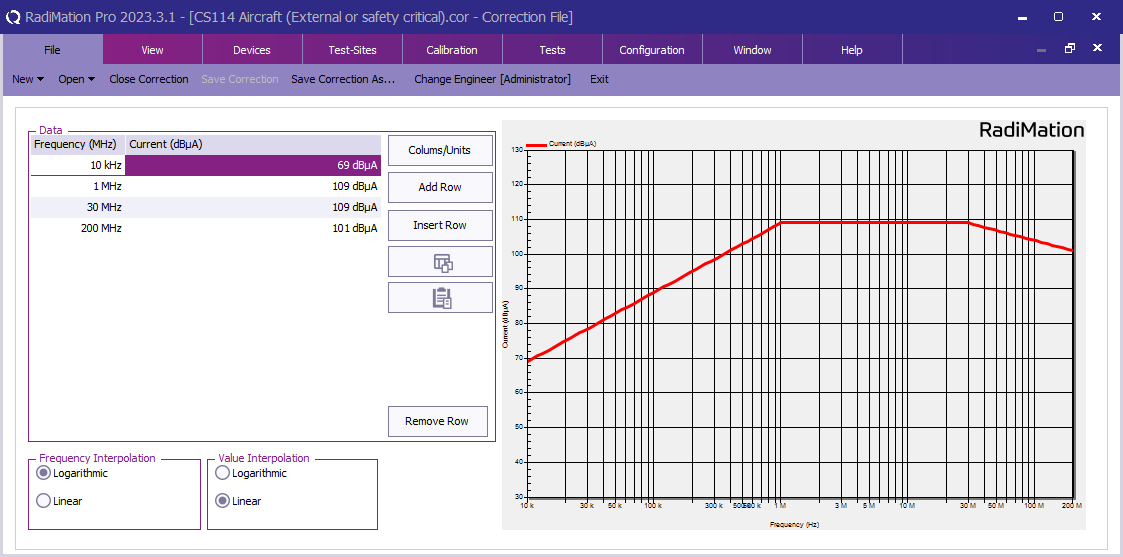

First create a correction file in RadiMation® and specify the applicable test level (See 'TABLE IV CS114 limit curves.' and 'FIGURE CS114-1. CS114 calibration limits.'). In this example the limits for 'Aircraft (External or safety critcal) / Curve 5 are configured.

Make sure to remove the Correction column and add the current column with the unit set to dBuV.

Create calibration test setup file[edit]

-

Calibration

Calibration

-

System calibration

System calibration

-

Conducted immunity

Conducted immunity

-

-

-