How to perform a magnetic field close proximity test[edit]

This RadiMation® application note explains how the close proximity radiated immunity magnetic field test can be performed with RadiMation®. This test is described in several standards, including the IEC 61000-4-39:2017 (section 8.5.1) and the MIL-STD-461 RS101.

A very similar test for the generation of magnetic field can also be done where the levelling is done on the forward power. Application Note 139: "How to perform a magnetic field close proximity test using forward power levelling" describes how that test can be performed.

Magnetic field tests[edit]

For the generation of the magnetic field, loop antennas are used, with the exact specifications of wire thickness and number of windings, as specified in the applicable standard. Several manufacturers are providing loop antennas based on these specifications.

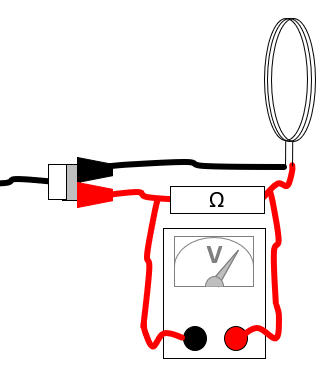

The current flowing through the loop antenna is a one on one relation to the generated magnetic field. For the measurement of the current, different measurement methods are available that can be used in combination with RadiMation®. It can be measured using a shunt resistor, or a current sensor. To characterise and validate the generated magnetic field, first a calibration is needed to determine the required amount of current through the loop antenna. The actually generated magnetic field is measured using another magnetic field monitoring loop connected to a frequency selective powermeter. The result of that calibration can then also be used during the actual substitution test.

Necessary equipment[edit]

The following test and measurement devices are needed:

- Signal generator

- Amplifier

- Transmitting loop antenna (according the specifications of the applicable standard)

- Cables

The current flowing through the loop antenna can be measured by one of the following methods, and depending on the used method, those additional test and measurement devices are also needed:

- Current sensor and powermeter

- Resistor and multimeter

- Resistor and oscilloscope

For the calibration of the magnetic field two additional test and measurement devices are also needed:

- Receiving loop antenna (according the specifications of the applicable standard)

- Measurement receiver

Calibration[edit]

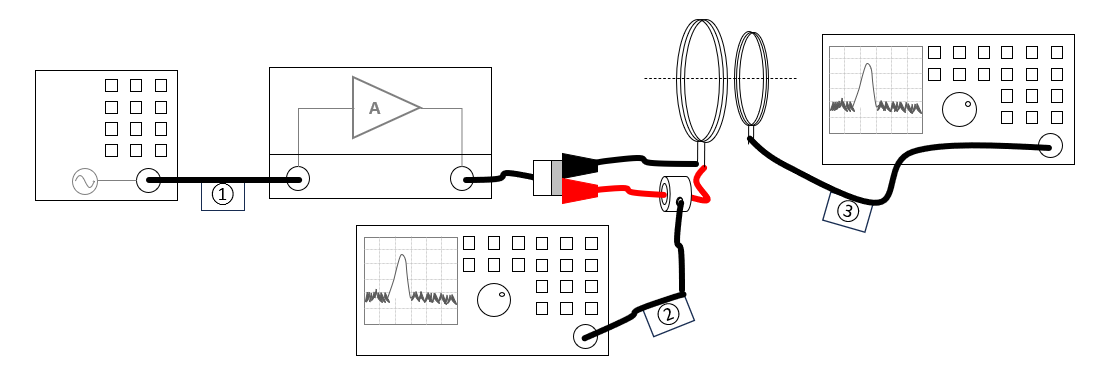

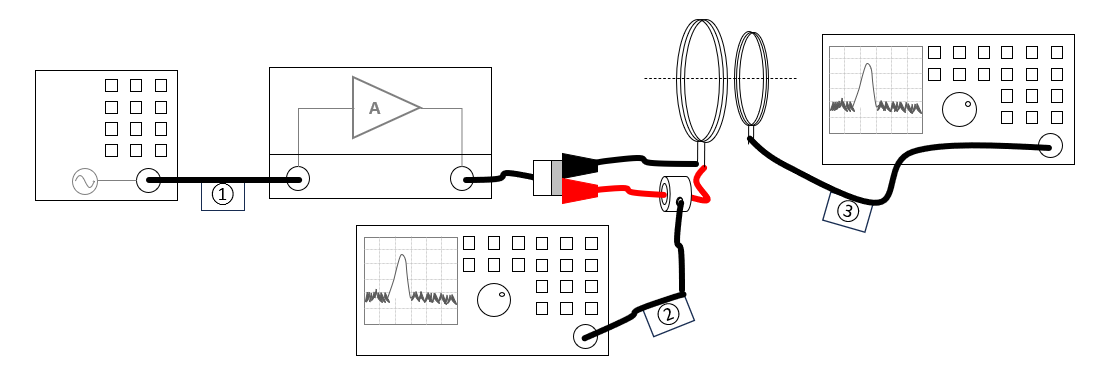

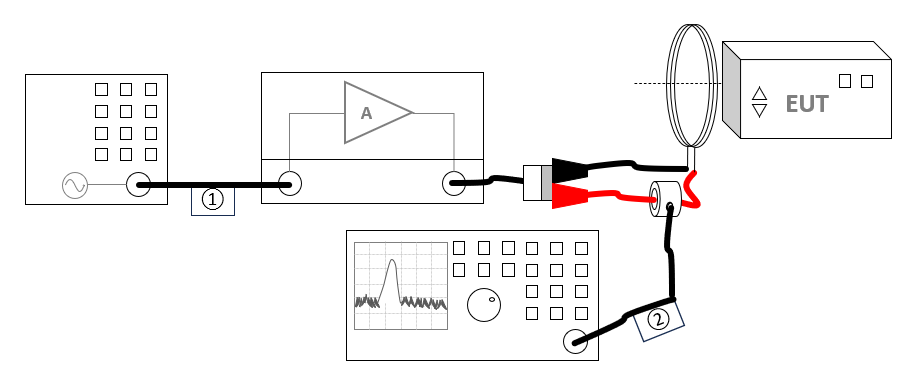

During the calibration the magnetic field transmitting loop and magnetic field monitoring loop are positioned close to each other, with a specified distance. The current through the magnetic field transmitting loop is then increased until the desired magnetic field level has been reached. The magnetic field monitoring loop connected to the measurement receiver is used to measure the actually generated magnetic field.

The configuration of the testsite should then contain the following devices:

| # |

Device name |

Tab in testsite configuration window |

note

|

|

Signal Generator |

Devices 1 |

|

|

Amplifier |

Devices 1 |

|

|

Antenna |

Devices 1 |

For the magnetic field generation loop antenna

|

|

Calibration Antenna |

Devices 1 |

For the magnetic field monitoring loop antenna. A Magnetic field factor (dBpT/μV) correction file should be attached to the used antenna device. See Magnetic Field Factor correction in Chapter 14

|

|

Current sensor |

Devices 2 |

A transfer impedance correction file should be attached to the used current sensor device. See Current sensor impedance correction in Chapter 14

|

|

Sensor powermeter |

Devices 2 |

|

|

Spectrum analyser |

Devices 2 |

For the measurement of the magnetic field monitoring antenna

|

| Cables

|

| ① |

Cable SG -> amplifier |

Cables |

Optional to correct for the cable loss between the signal generator and the amplifier

|

| ② |

Cable current -> power meter |

Cables |

Optional to correct for the cable loss between the current sensor and the sensor power meter

|

| ③ |

Cable antenna -> preamp |

Cables |

Optional to correct for the cable loss between the calibration antenna and the spectrum analyser

|

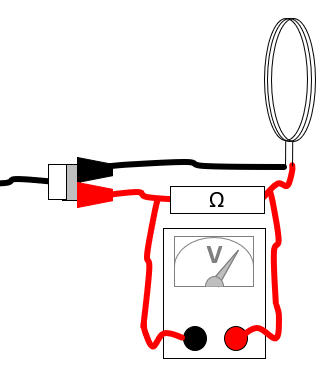

Instead of using a current sensor and powermeter, it is also possible to use a shunt resistor and a multimeter, or use the oscilloscope instead of the multimeter

The configuration of the testsite should then contain the following devices:

| # |

Device name |

Tab in testsite configuration window |

note

|

|

Signal Generator |

Devices 1 |

|

|

Amplifier |

Devices 1 |

|

|

Antenna |

Devices 1 |

For the magnetic field generation loop antenna

|

|

Calibration Antenna |

Devices 1 |

For the magnetic field monitoring loop antenna. A Magnetic field factor (dBpT/μV) correction file should be attached to the used antenna device. See Magnetic Field Factor correction in Chapter 14

|

|

Resistor |

Devices 1 |

The actual resistor value should be specified in the advanced settings of the used resistor device.

|

|

Multimeter |

Devices 1 |

Only needed if a multimeter is used for the measurement of the voltage over the resistor

|

|

Oscilloscope |

Devices 1 |

Only needed if an oscilloscope is used for the measurement of the voltage over the resistor

|

|

Spectrum analyser |

Devices 2 |

For the measurement of the magnetic field monitoring antenna

|

| Cables

|

| ① |

Cable SG -> amplifier |

Cables |

Optional to correct for the cable loss between the signal generator and the amplifier

|

| ② |

Cable current -> power meter |

Cables |

Optional to correct for the cable loss between the current sensor and the sensor power meter

|

| ③ |

Cable antenna -> preamp |

Cables |

Optional to correct for the cable loss between the calibration antenna and the spectrum analyser

|

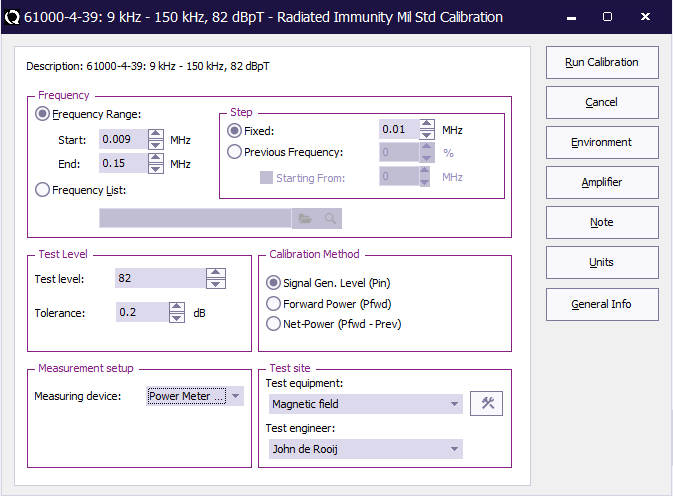

The Magnetic field calibration can be started in RadiMation® by selecting from the menu:

-

Calibration

Calibration

-

System Calibration

System Calibration

-

Radiated Immunity

Radiated Immunity

-

Mil Std Calibration

Mil Std Calibration

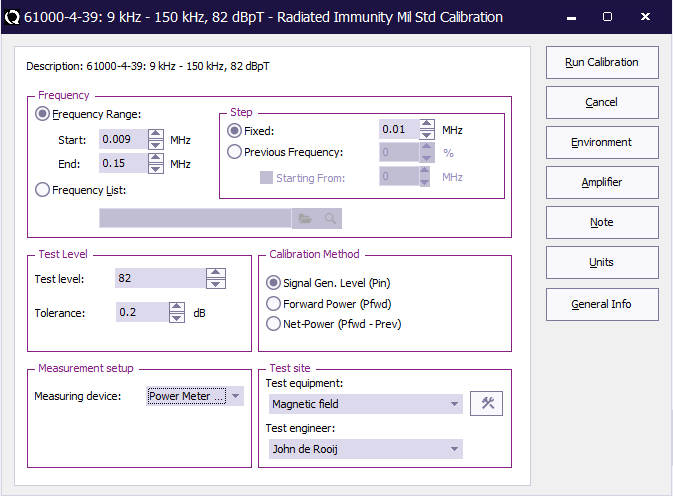

In the Mil Std Calibration dialog, the required settings can be configured. The applicable standard often specifies most of these settings.

Start Start

|

The start frequency of the calibration. For example 9 kHz.

|

End End

|

The end frequency of the calibration. For example 150 kHz.

|

Step Fixed Step Fixed

|

The frequency step that should be used to increment the frequency. For example 10 kHz.

|

Step Logarithmic Step Logarithmic

|

The percentage of the frequency that should used to increment the frequency. For example 1 %.

|

Test level Test level

|

The desired magnetic field testlevel that should be calibrated. For example 82 dBpT.

|

Tolerance Tolerance

|

The tolerance (specified in dB) that should be used for the accuracy of the regulated testlevel. For example: 0.2 dB.

|

Calibration method Calibration method

|

The power level(s) (signal power, forward power or netto power) that should be measured and stored in the calibration file.

|

Measuring device Measuring device

|

The device that is used for the measurement of the selected coupling device. This can be Multimeter and Resistor, Powermeter and Current sensor or Oscilloscope and Resistor.

|

Test equipment Test equipment

|

The name of the testsite that should be used. This testsite should at least have all the required equipment.

|

Test engineer Test engineer

|

The name of the engineer who is performing the calibration.

|

Depending on the applicable standard, the test level is often specified in dBpT, dBμA/m or A/m. The Units button can be used to change which unit should be used for the Magnetic Field to specify the Test level.

When this calibration is started, the signal generator will generate every frequency, and the current through the loop antenna is regulated to the desired magnetic field level as it is measured by the Spectrum Analyser and the Calibration antenna. Once the desired magnetic field is regulated, the current through the magnetic field generation loop is measured, which will also stored together with the power level in the calibration. At the end of the system calibration a 'Save Calibration As' dialog is shown, which allows to save the result of the calibration to a .CAL calibration file.

It is advised to specify a useful location and filename for this magnetic field calibration file.

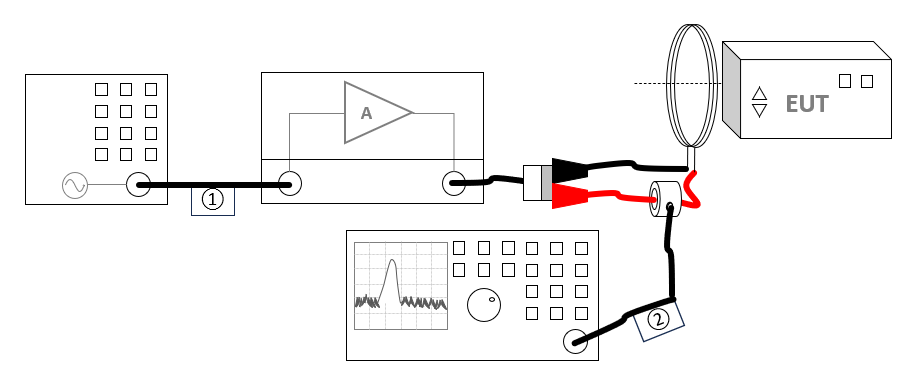

EUT measurement[edit]

Once the system calibration has been performed, the EUT can be installed and prepared. Also open an EUT file in RadiMation® to store the measurement results of the tests.

The equipment configuration that is needed for the actual test is very similar to the calibration setup.

To perform the real magnetic field close proximity test, the earlier created calibration file can be used to generate the requested magnetic field.

Just use a Radiated Immunity Multiband test by selecting from the menu:

-

Tests

Tests

-

Radiated Immunity

Radiated Immunity

-

Multiband

Multiband

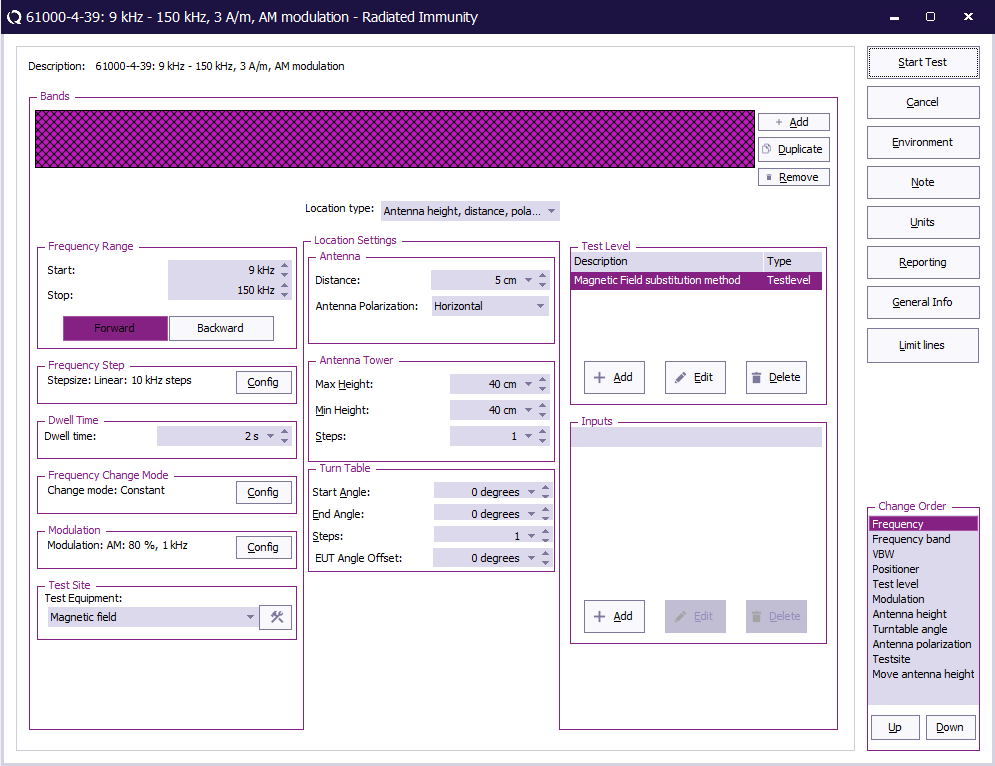

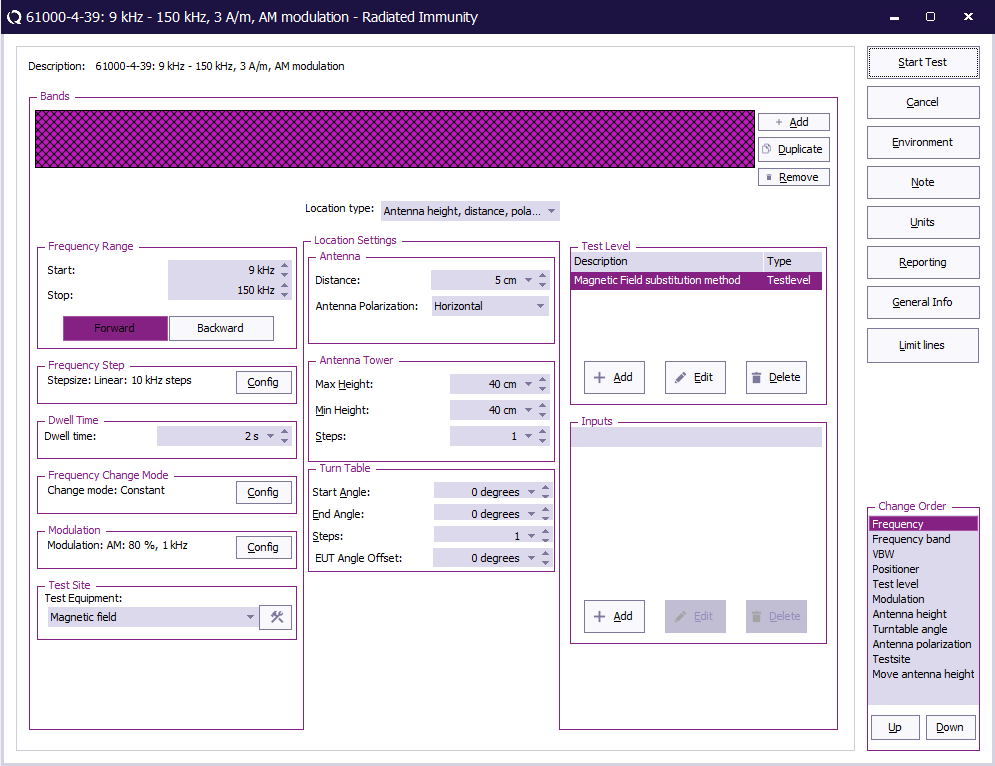

All the desired test parameters can be set in this configuration window:

Start Start

|

The start frequency of the test. For example 9 kHz.

|

Stop Stop

|

The stop frequency of the test. For example 150 kHz.

|

Frequency step Frequency step

|

The frequency step that should be used to increment the frequency. For example 10 kHz.

|

Dwell time Dwell time

|

The dwell time that should be used at every frequency. For example 2 seconds.

|

Frequency change mode Frequency change mode

|

The mode that should be used to change from one frequency to the next frequency.

|

Modulation Modulation

|

The modulation that should be applied during the dwell time at each frequency.

|

Test equipment Test equipment

|

The name of the testsite that should be used. This testsite should at least have all the required equipment.

|

Location type Location type

|

The type of test that should be used. For a magnetic field test use Antenna height, distance, polarization and angle.

|

Antenna distance Antenna distance

|

The used distance between the antenna and the EUT. For example 5 cm.

|

Antenna polarisation Antenna polarisation

|

The polarisation of the antenna related to the EUT. For a loop antenna, just specify Horizontal.

|

Antenna tower Antenna tower

|

The minimum, maximum and number of heights that should be moved with an automated antenna tower.

|

Turn table Turn table

|

The start and end angle and how many angles should be measured with an automated turntable.

|

Test level Test level

|

The configuration of the testlevels and limits that should be used during the regulation of the test.

|

Inputs Inputs

|

The configuration of additional inputs that should be measured during the test.

|

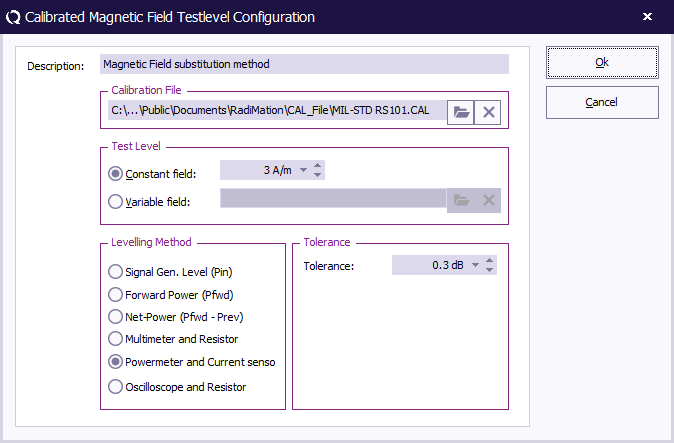

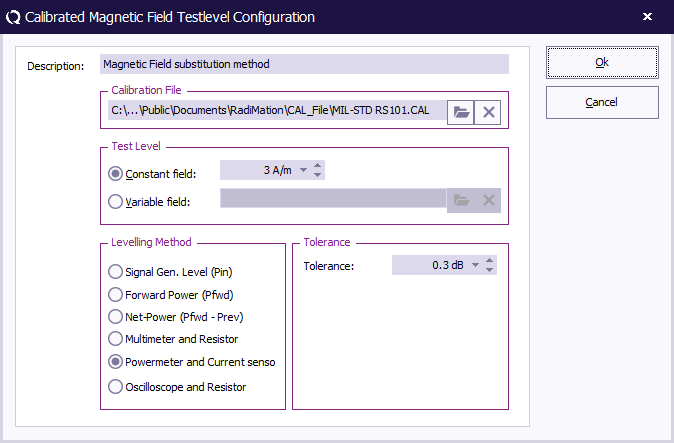

In the test configuration a Magnetic Field substitution method testlevel can be added. In the Magnetic Field substitution method testlevel configuration the .CAL file can be selected again, and the requested testlevel can be specified. In this configuration dialog, also the levelling method can be selected, which also has the option to regulate on the current flowing through the magnetic field generation loop.

Description Description

|

Specifies the name that should be used for this testlevel.

|

Calibration file Calibration file

|

The calibration file which is the result of the system calibration, and which is now used to regulate to the desired testlevel.

|

Testlevel constant field Testlevel constant field

|

The desired testlevel for the magnetic field.

|

Testlevel variable field Testlevel variable field

|

A correction file that should be used to for a frequency depending testlevel, which allows to do variation of the magnetic field strength over the frequency.

|

Levelling method Levelling method

|

Which device combination should be used to regulate the power and/or current, and thus also the magnetic field.

|

Tolerance Tolerance

|

The tolerance (specified in dB) that should be used for the accuracy of the regulated testlevel. For example: 0.3 dB.

|

Depending on the applicable standard, the test level is often specified in dBpT, dBμA/m or A/m. The Units button can be used to change which unit should be used for the Magnetic Field to specify the Testlevel constant field.

The requested test level doesn't need to be the same as the calibrated magnetic field, as RadiMation® will automatically calculate the corresponding current if another testlevel is specified.

When this test is started, the signal generator will be set to every frequency again, and the current flowing through the transmitting loop antenna will be regulated to the current that is determined during the calibration, which correlates to the requested magnetic field.

Once the EUT test is finished, the results of this test is stored in the EUT file, and available as one of the performed Tests in the EUT file. Selecting the corresponding test result and pressing on Info will show the test results again.

The magnetic field transmitting loop should be located close to the EUT itself. If the EUT is larger than the illumination area of the transmitting loop, the same magnetic field test has to be repeated for example for every 50cm x 50cm area of the EUT. Also all sides of the EUT have to be tested. This can be easily done by repositioning the loop antenna, and starting the same test in RadiMation® again.

Conclusion[edit]

The RadiMation® Radiated Immunity Mil Std calibration can be used to characterise the generated magnetic field by measuring the current through the transmitting loop, and storing it in a calibration file.

The Multiband Radiated Immunity test can then use the calibration file to re-apply the required current (and thus the desired magnetic field) again. This test can then be used to test if the EUT is not influenced by the generated magnetic field.

Calibration

Calibration

System Calibration

System Calibration

Radiated Immunity

Radiated Immunity

Mil Std Calibration

Mil Std Calibration  Tests

Tests

Radiated Immunity

Radiated Immunity

Multiband

Multiband