Agilent Technologies U2000A: Difference between revisions

No edit summary |

DevicesBot (talk | contribs) (Updated DeviceDriverInfo template) |

||

| Line 4: | Line 4: | ||

|DeviceDriverName=AGILENTU2000A | |DeviceDriverName=AGILENTU2000A | ||

|DeviceType=U2000A | |DeviceType=U2000A | ||

|HideAutoData=1 | |||

|SupportedDeviceTypes=8 | |SupportedDeviceTypes=8 | ||

}} | }} | ||

{{:Agilent Technologies U2000 Series}} | {{:Agilent Technologies U2000 Series}} | ||

Latest revision as of 12:19, 11 February 2020

The Agilent Technologies U2000A device driver is a Power Meter which is supported by RadiMation®.

Configuration[edit]

The following tabs are available in the advanced configuration of the Agilent Technologies U2000A:

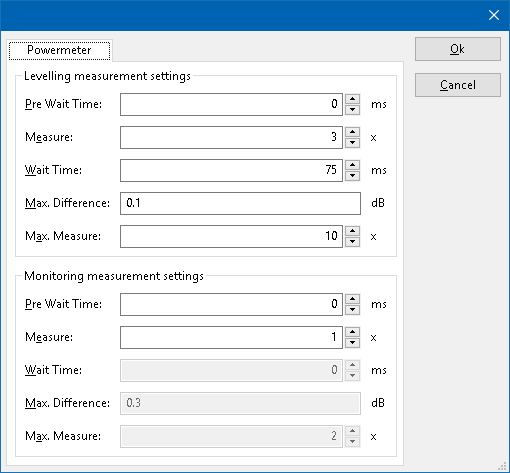

| Wait time before starting the measurement-loop. Can be used to wait for a signal generator, and or amplifier to stabilize. |

| The minimum amount of measurements in the measure loop. Continues to loop even if power level is stable. |

| The wait time between each measurement is taken, during the measurement-loop. |

| If the measured power between each measurement in the measurement-loop, is less than this value. The measured power is stable. The measurement-loop will then stop. |

| The maximum amount of measure times, for the measurement-loop |

According to these settings, RadiMation® will perform a minimum of 3 power measurements with a wait time between the measurements of 75ms. If all those 3 measurements are within 0.1 dB, the power measurement is assumed to be stable, and RadiMation® will continue to average of the last 3 measurements. If the difference between the measurements is larger than the specified 0.1 dB, an additional power measurement will be performed, and the last 3 samples will be compared to the 0.1 dB difference again. At most 10 measurements will be performed if the difference between the 3 samples will not be within the specified 0.1 dB.

Both for the leveling, and the monitoring these settings can be set individually. The leveling is used, whenever RadiMation® is measuring the power, to regulate the signal generator. If the powermeter is only used as input, without regulating on it, then the monitoring settings are used.

More detailed information on how to achieve a fast and stable power measurement is available in Application Note 106: Powermeter parameter configuration.

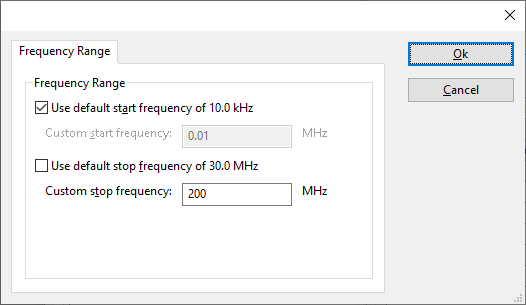

The frequency range of the Agilent Technologies U2000A as provided by the manufacturer is shown and selected as default. It is possible to overrule these frequencies and to manually adjust the allowed frequency range of the Agilent Technologies U2000A.

| If the checkbox is checked, the default start frequency will be used as the lowest usable frequency in a test for this device. |

| If the Use default start frequency checkbox is unchecked, another start frequency (expressed in MHz) can be specified. The customized start frequency will then be used as the lowest usable frequency in a test for this device. The customized frequency can be a limitation or an extension of the default start frequency. |

| If the checkbox is checked, the default stop frequency will be used as the highest usable frequency in a test for this device. |

| If the Use default stop frequency checkbox is unchecked, another stop frequency (expressed in MHz) can be specified. The customized stop frequency will then be used as the highest usable frequency in a test for this device. The customized frequency can be a limitation or an extension of the default stop frequency. |

Specifying a different frequency range can be useful if for example:

- A device (like a coupler, antenna, injection device, cable, etc...) is still usable (but out of specification) outside the standard suggested frequency range.

- An external mixer is used to measure an extended frequency range.

- An up- or down-convertor is used to shift the frequency range.

- A newer model of a device is present that has an extended frequency range, and still uses the same remote control commands.

Be careful changing these settings as RadiMation® is no longer able to verify if the Agilent Technologies U2000A is used outside frequency range that is specified by the manufacturer. This may result in serious damage to your measurement device.

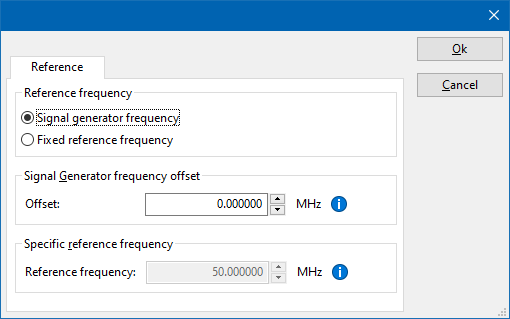

The settings on the Reference tab influence the measurement frequency that is communicated to the measurement device. The frequency that is forwarded to the measurement device can for example be used by the device to perform the measurement on the correct frequency, or use the correct internal frequency dependant correction or calibration factor on the measurement result. Normally it is desired that the measurement frequency is the same as the carrier frequency of the signal generator. In some situations it can however be required to communicate a different frequency to the measurement device. In such a situation the settings on the Reference tab can be modified.

| Selects that the actual carrier frequency of the signal generator is communicated to the measurement device. This is the default behaviour. |

| Selects that a fixed frequency (independent of the signal generator carrier frequency) is communicated to the measurement device. |

| An additional offset frequency specified in MHz, that is added to frequency that is communicated to the measurement device. This value can be positive or negative, and defaults to 0.0 MHz. |

| The fixed reference frequency specified in MHz that is communicated to the measurement device, when the Fixed reference frequency option is selected. |

| Warning: | When a different reference frequency is specified and communicated to the measurement device, it is only relevant for the measurement device. A correction file that is attached to the device driver in RadiMation® will still use the correction value that is specified for the actual signal generator carrier frequency. |

Additional Information[edit]

When configuring the Agilent Technologies U2000A be aware of the following.

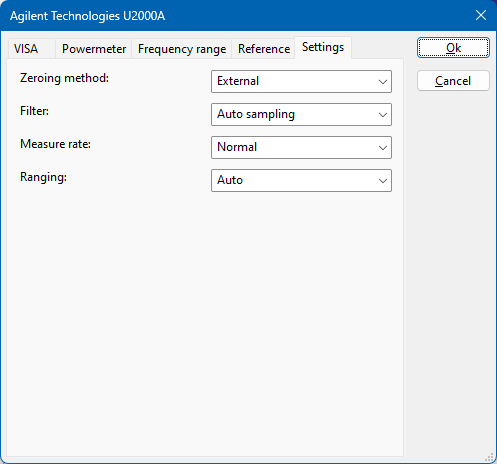

There are four settings that can be set for the Agilent Technologies U2000A in advanced device driver settings dialog of the device driver in the RadiMation® software. The ones that have influence on the measurement time are Filter, Measure rate and Ranging.

Here are the explanations from the settings:

Zeroing Method

Here you select the zeroing method used. This setting has no influence on the speed or accuracy.

Filter

When you use auto sampling for the filter setting the settling times are related to the dBm value. Check the spec-sheet on page 16 for a tabel on the times the powermeter needs to settle related to the dBm value.

Due to long measurement times it could raise problems if ‘auto-filter’ is selected. Eg. -40 dBm value translates to 42 sec on 'normal' speed and 24 sec on 'double' speed.

It probably is better to select a fixed filter number, but which filter should be selected is however depending on the expected powerlevels that are being measured. For more information on this setting please check the manual on the Keysight website. On page 43 there is a paragraph about measurement speed and accuracy.

This is important to read as it tells you the trade-offs between speed and accuracy.

Measure rate

Measure rate generally can be set to 'x2' (also called 'Double') This speeds up the measurement (See the table mentioned earlier)

Ranging

The ranging parameter determines if the 'High' power path or the 'Low' power path or 'Auto'-selection is being used, as described on page 11 of the datasheet. This also can have influence on the measurement time.

Conclusion[edit]

As you see these parameters influence each other. So the optimum setting for these can differ. It's also depended of the input level and it could be needed to have different settings to run different tests. Another aspect is the accuracy and the speed you need and which settings are optimal.

If you find yourself switching between a set of optimal settings for different tests you could make separate test-sites. These would have the same devices but different settings for the powermeter.

Eg. one for very quick but not so accurate tests and one for the opposite.