Chapter 6: Difference between revisions

Tag: Reverted |

|||

| Line 169: | Line 169: | ||

When a new TSF file is loaded (by pressing New in the TSF selection window) all parameters will be at zero and can be configured by the operator. | When a new TSF file is loaded (by pressing New in the TSF selection window) all parameters will be at zero and can be configured by the operator. | ||

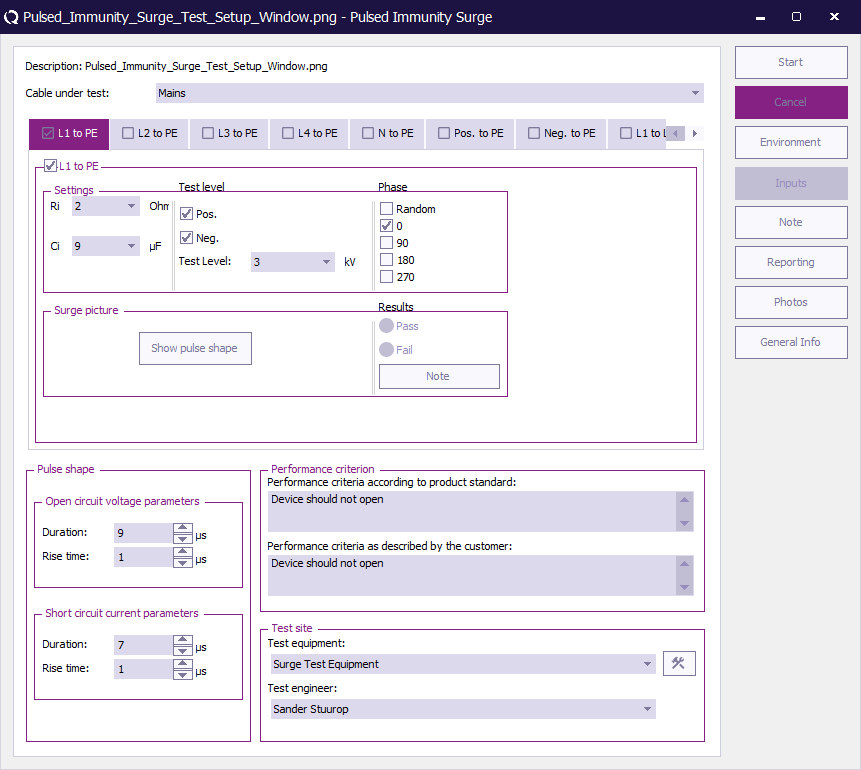

The picture below shows the surge test configuration screen. | The picture below shows the surge test configuration screen. | ||

| Line 178: | Line 177: | ||

All configurations (except for the test results) can be stored in a TSF file. | All configurations (except for the test results) can be stored in a TSF file. | ||

=Voltage dips and interrupts testing= | |||

==Starting a Voltage dips and interrupts test== | |||

==Starting a | |||

===Loading a TSF file=== | ===Loading a TSF file=== | ||

To start a | To start a VDI test, an EUT file must be defined first. From the EUT file, select | ||

{{menu|Tests|Pulsed immunity| | {{menu|Tests|Pulsed immunity|Voltage dips and interrupts}} | ||

A list of Technical Setup Files (TSF files) will be displayed. The test engineer can select one of these TSF files to load all parameters from a | A list of Technical Setup Files (TSF files) will be displayed. The test engineer can select one of these TSF files to load all parameters from a voltage dips and interrupts defined test or press cancel to define a new voltage dips and interrupts test. | ||

After the TSF file has been selected, the | After the TSF file has been selected, the voltage dips and interrupts configuration window will appear. | ||

When a TSF file is loaded, all test parameters will be already configured and pressing the start button on the right side of the screen will start the test. | When a TSF file is loaded, all test parameters will be already configured and pressing the start button on the right side of the screen will start the test. | ||

| Line 212: | Line 191: | ||

When a new TSF file is loaded (by pressing New in the TSF selection window) all parameters will be at zero and can be configured by the operator. | When a new TSF file is loaded (by pressing New in the TSF selection window) all parameters will be at zero and can be configured by the operator. | ||

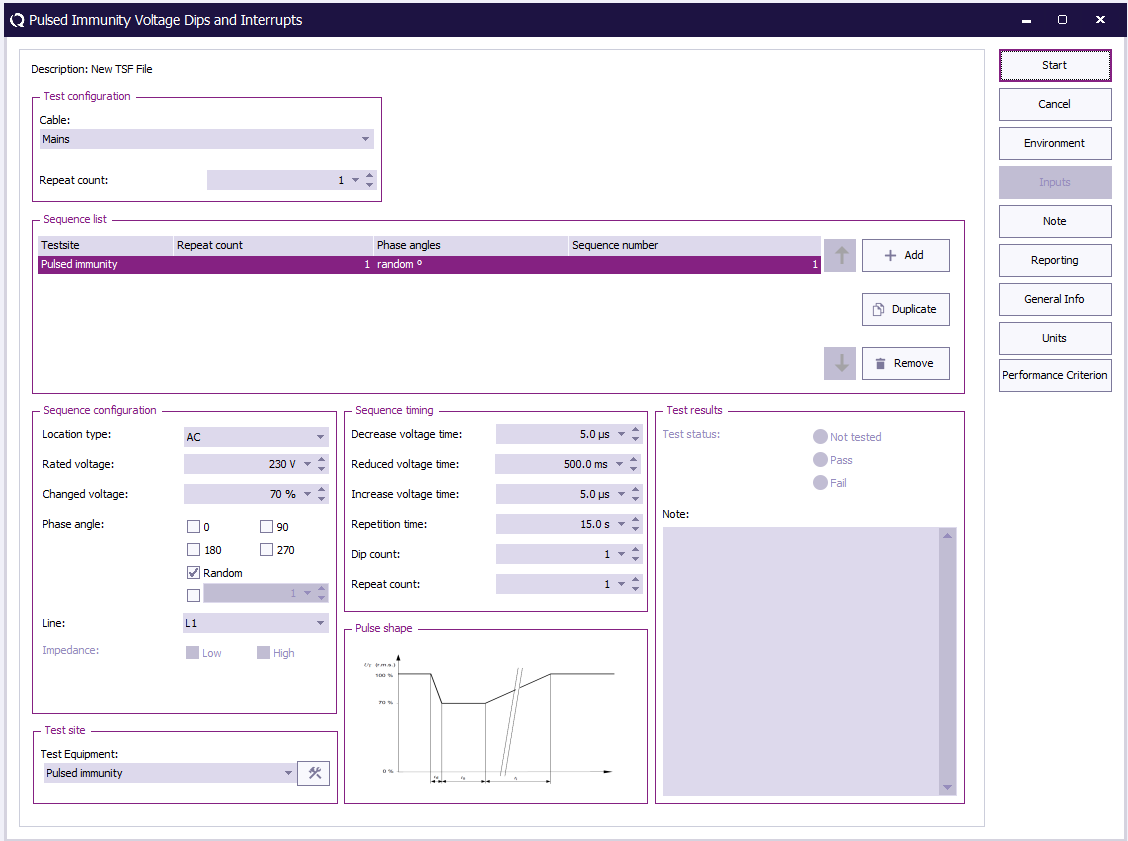

The picture below shows the | The picture below shows the voltage dips and interrupts test configuration screen. | ||

[[Image: | [[Image:PI_VDI_MB_CONFIGURATION.png]] | ||

The operator | The operator has to select cable to be tested (1 or 3 phase / DC / IO). The cable under test is part of the EUT so it needs to be configured in the EUT window under [[Chapter_3#EUT Information tab|cables]]. Furthermore the operator has to configure the test level, polarity, phase and the internal resistor and capacitor of the generator. The measurement results can be recorded in the right side of the screen. For each injection mode, the operator can select pass or fail and make notes in the “notes” field. | ||

All configurations (except for the test results) can be stored in a TSF file. | |||

All configurations (except for test results) can be | |||

{{ScreenElementDescription|Cable | {{ScreenElementDescription|Cable|Selection of the mains cable on which this pulsed-immunity test will be applied. The cable is created and managed in the EUT window.}} | ||

{{ScreenElementDescription|Repeat count|Defines how many times the complete test configuration is executed.}} | |||

{{ScreenElementDescription|Repeat count|Defines how many times the complete | {{ScreenElementDescription|Location type|Defines the supply type for the sequence (AC or DC).}} | ||

{{ScreenElementDescription|Rated voltage|Nominal supply voltage applied to the EUT during the test.}} | |||

{{ScreenElementDescription| | {{ScreenElementDescription|Changed voltage|Percentage of the rated voltage applied during the dip or interruption.}} | ||

{{ScreenElementDescription|Phase angle selection|Allows selection of one or more fixed phase angles (0°, 90°, 180°, 270°) or randomized angle triggering.}} | |||

{{ScreenElementDescription| | {{ScreenElementDescription|Line|Selection of the line on which the voltage dip or interruption is applied.}} | ||

{{ScreenElementDescription| | {{ScreenElementDescription|Impedance|Selection of the output impedance level of the generator (Low or High).}} | ||

{{ScreenElementDescription|Phase angle| | {{ScreenElementDescription|Decrease voltage time|Time required for the voltage to ramp down to the reduced level.}} | ||

{{ScreenElementDescription| | {{ScreenElementDescription|Reduced voltage time|Duration for which the reduced voltage level is maintained.}} | ||

{{ScreenElementDescription| | {{ScreenElementDescription|Increase voltage time|Time required for the voltage to ramp back up to rated level.}} | ||

{{ScreenElementDescription|Repetition time|Total time interval between successive pulses in the sequence.}} | |||

{{ScreenElementDescription|Dip count|Number of dips generated within this sequence.}} | |||

{{ScreenElementDescription|Repeat count|How many times this timing sequence is executed within the selected sequence configuration.}} | |||

{{ScreenElementDescription| | {{ScreenElementDescription|Pulse shape| | ||

{{ScreenElementDescription|Pulse diagram|Graphical representation of the pulse form, showing the timing of the drop, hold, and recovery of voltage during the dip/interrupt event.}} | |||

{{ScreenElementDescription| | {{ScreenElementDescription|Test status|Indicates whether the selected sequence has not been tested, passed, or failed.}} | ||

{{ScreenElementDescription| | {{ScreenElementDescription|Note|Field where the test engineer can enter observations, deviations, or test-related remarks.}} | ||

{{ScreenElementDescription| | {{ScreenElementDescription|Test equipment|Selection of the equipment list to be used for this sequence. The list is defined and maintained in the equipment configuration.}} | ||

{{ScreenElementDescription| | {{ScreenElementDescription|Equipment icon|Opens the equipment list for viewing or editing.}} | ||

{{ScreenElementDescription| | |||

{{ScreenElementDescription|Pulse | |||

{{ScreenElementDescription|Pulse | |||

{{ScreenElementDescription| | |||

{{ScreenElementDescription| | |||

{{ScreenElementDescription|Test | |||

{{ScreenElementDescription| | |||

[[Category:Manual]] | [[Category:Manual]] | ||

Revision as of 11:23, 24 November 2025

Pulsed immunity[edit]

Introduction[edit]

The pulsed immunity test modules are used to record test data in the RadiMation® software. Some of the pulsed immunity tests are carried out manually while the test engineer enters the test results. The report generator can use the results of the tests.

The following pulsed immunity tests are implemented:

- Electro static discharge (ESD) testing

- Electrical Fast Transient (EFT) testing

- Surge testing

- Voltage dips and interrupts (VDI) testing

ESD testing[edit]

Starting an ESD test[edit]

Loading a TSF file[edit]

To start an ESD test, an EUT file must be defined first. From the EUT file, select

-

Tests

Tests

-

Pulsed immunity

Pulsed immunity

-

ESD

ESD

-

-

-

A list of Technical Setup Files (TSF files) will be displayed. The test engineer can select one of these TSF files to load all parameters from a previously defined ESD test or press cancel to define a new ESD test.

After the TSF file has been selected, the ESD configuration window will appear.

When a TSF file is loaded, all test parameters will be already configured and pressing the start button on the right side of the screen can start the test.

When a new TSF file is loaded (by pressing New in the TSF selection window) all parameters will be at zero and can be configured by the operator.

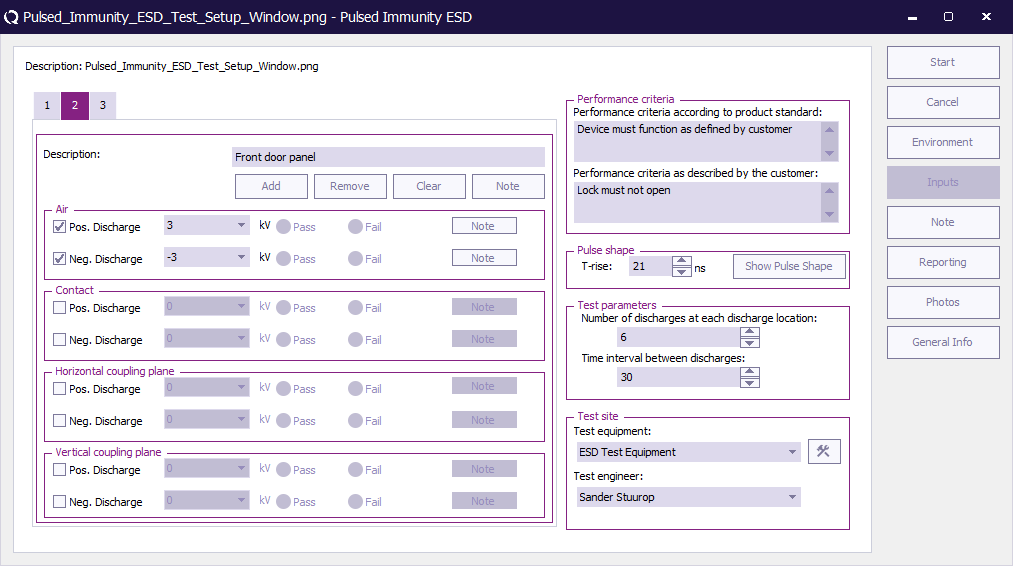

The picture below shows the ESD configuration screen. The operator has to select test levels and pulse polarity. Furthermore the burst waveform has to be configured by the operator. The measurement results can be recorded in the right side of the screen. For each injection mode, the operator can select pass or fail and make notes in the “notes” field.

All configurations (except for the test results) can be stored in a TSF file.

EFT testing[edit]

Starting a single band EFT test[edit]

Loading a TSF file[edit]

To start an EFT test, an EUT file must be defined first. From the EUT file, select

-

Tests

Tests

-

Pulsed immunity

Pulsed immunity

-

EFT

EFT

-

-

-

A list of Technical Setup Files (TSF files) will be displayed. The test engineer can select one of these TSF files to load all parameters from a previously defined EFT test or press cancel to define a new EFT test.

After the TSF file has been selected, the EFT configuration window will appear.

When a TSF file is loaded, all test parameters will be already configured and pressing the start button on the right side of the screen can start the test.

When a new TSF file is loaded (by pressing New in the TSF selection window) all parameters will be at zero and can be configured by the operator.

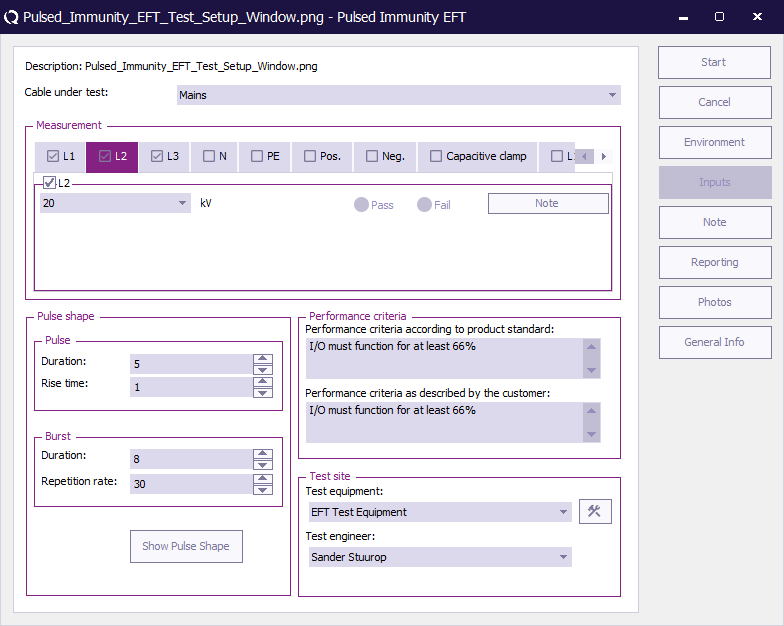

The picture below shows the EFT configuration screen.

The operator has to select the cable to be tested (AC / DC / IO). The cable under test is part of the EUT so it needs to be configured in the EUT window under cables. Furthermore the burst waveform has to be configured by the operator. The measurement results can be recorded in the right side of the screen. For each injection mode, the operator can select pass or fail and make notes in the “notes” field. All configurations (except for the test results) can be stored in a TSF file.

| Selection of cable on which the test is performed. The cable is created in the cable section in the EUT window. |

Configuration of the tests that need to be performed on the specific cable.

|

These parameters describe the characteristics of the applied pulses.

|

|

|

Starting a multiband test[edit]

Loading a TSF file[edit]

To start an EFT test, an EUT file must be defined first. From the EUT file, select

-

Tests

Tests

-

Pulsed immunity

Pulsed immunity

-

EFT Multiband

EFT Multiband

-

-

-

A list of Technical Setup Files (TSF files) will be displayed. The test engineer can select one of these TSF files to load all parameters from a previously defined EFT test or press cancel to define a new EFT test.

After the TSF file has been selected, the EFT configuration window will appear.

When a TSF file is loaded, all test parameters will be already configured and pressing the start button on the right side of the screen can start the test.

When a new TSF file is loaded (by pressing New in the TSF selection window) all parameters will be at zero and can be configured by the operator.

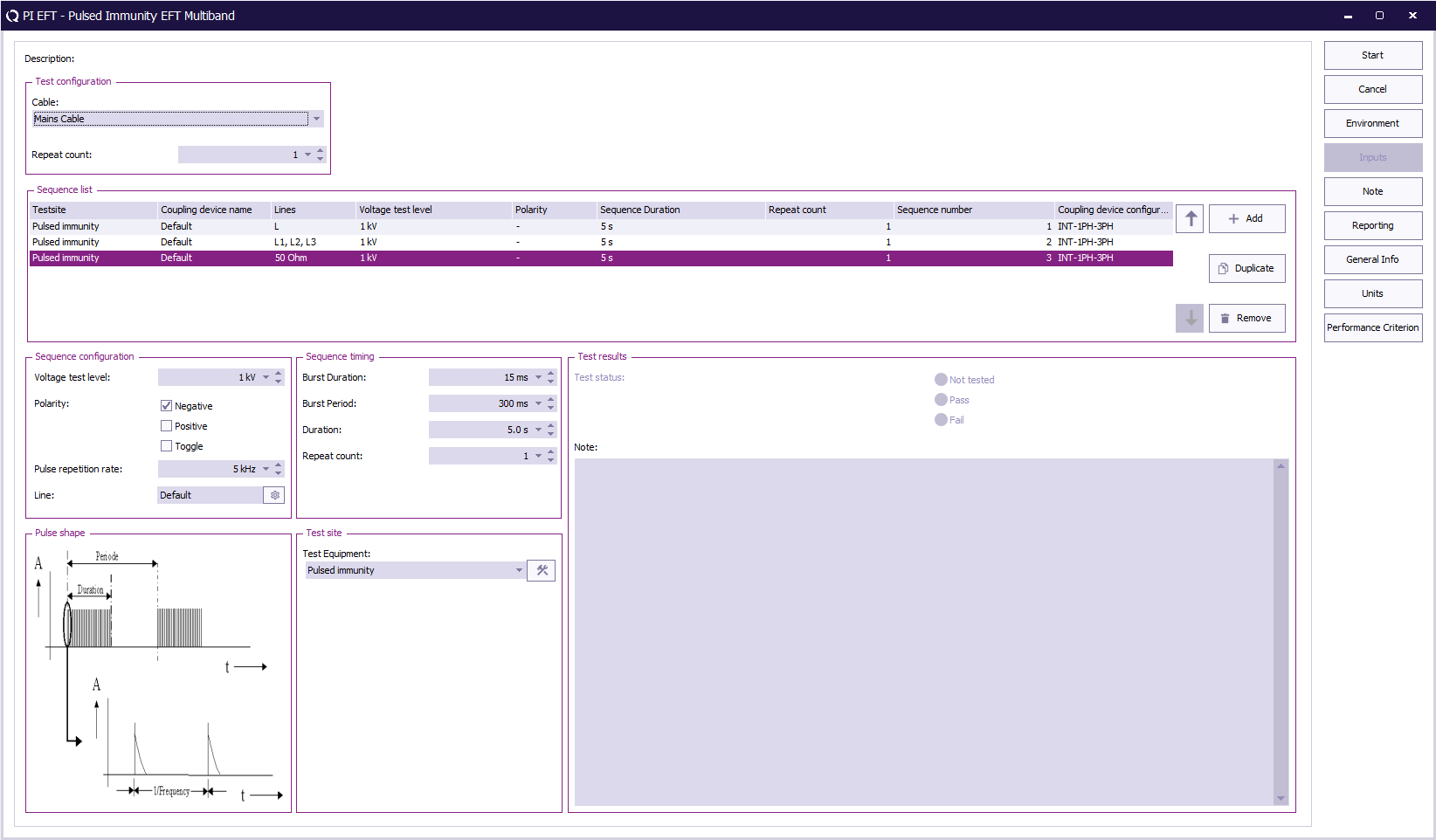

The picture below shows the EFT Multiband configuration screen.

The operator has to select the cable to be tested (AC / DC / IO). The cable under test is part of the EUT and therefore must be configured in the EUT window under cables.

Within this window, the operator defines the test levels, timing, and coupling line configuration for each EFT sequence. Measurement results can be entered on the right side of the screen, where each test step can be marked as Pass or Fail. All configurations (except for the test results) can be stored in a TSF file for later use.

| Selection of the cable on which the EFT test is performed. The cable is defined in the EUT configuration under Cables. |

| Defines how many times the complete EFT test configuration is executed. |

| Overview of all EFT test sequences to be performed. |

| Specifies the burst voltage level to be applied. |

| Defines whether the burst polarity is positive, negative, or toggling. |

| Shows the selected coupling device setup. |

| Shows the selected coupling device. |

| Buttons to create, copy, or delete EFT sequences from the list. |

| Defines the test parameters for the currently selected EFT sequence. |

| Sets the test voltage level for the EFT burst. |

| Determines if the pulses are positive, negative, or alternating. |

| Sets the frequency of the pulses within the burst. |

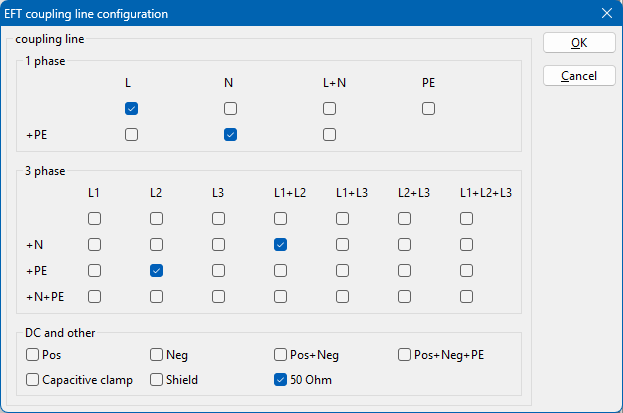

| Shows the selected coupling device and is used to opens the Coupling Line Configuration dialog where the operator defines which coupling lines are used for the EFT test.

The coupling line Configuration dialog allows the selection of the coupling line configuration for the device driver found in the testsite. The operator can select one or more combinations, depending on the test standard requirements. If no coupling path is selected the pre-existing configuration will not be overwritten. The coupling line configuration dialog does not remember the previous selected line selection. Each selected line is tested sequentially; RadiMation automatically creates individual EFT injections for each configuration. Selecting multiple lines ensures all required coupling paths are tested without manual re-configuration between runs. If no line is selected when starting the test, RadiMation prompts the user to select at least one coupling path before the test can start. When multiple coupling paths are selected, RadiMation automatically performs a separate test for each selection in sequence. The order in which testing on the coupling lines is performed is undefined. |

| Note: | The coupling configuration dialogue is added in RadiMation 2025.2.1, in older RadiMation releases a single tested coupling line is selected from a predefined list. |

| Defines timing values used for the EFT bursts. |

| The duration of a single burst of pulses. |

| The interval between two bursts. |

| Total time that the sequence runs. |

| Number of times the sequence is repeated. |

| Displays a visual representation of the EFT pulse and burst waveform. |

| Displays the selected test generator or system used for the EFT test. |

| Shows the test status (Not tested, Pass, or Fail) and allows the operator to add notes related to the test. |

Surge testing[edit]

Starting a single band surge test[edit]

Loading a TSF file[edit]

To start a Surge test, an EUT file must be defined first. From the EUT file, select

-

Tests

Tests

-

Pulsed immunity

Pulsed immunity

-

Surge

Surge

-

-

-

A list of Technical Setup Files (TSF files) will be displayed. The test engineer can select one of these TSF files to load all parameters from a previously defined emission test or press cancel to define a new surge test.

After the TSF file has been selected, the surge configuration window will appear.

When a TSF file is loaded, all test parameters will be already configured and pressing the start button on the right side of the screen will start the test.

When a new TSF file is loaded (by pressing New in the TSF selection window) all parameters will be at zero and can be configured by the operator.

The picture below shows the surge test configuration screen.

The operator has to select cable to be tested (1 or 3 phase / DC / IO). The cable under test is part of the EUT so it needs to be configured in the EUT window under cables. Furthermore the operator has to configure the test level, polarity, phase and the internal resistor and capacitor of the generator. The measurement results can be recorded in the right side of the screen. For each injection mode, the operator can select pass or fail and make notes in the “notes” field. All configurations (except for the test results) can be stored in a TSF file.

Voltage dips and interrupts testing[edit]

Starting a Voltage dips and interrupts test[edit]

Loading a TSF file[edit]

To start a VDI test, an EUT file must be defined first. From the EUT file, select

-

Tests

Tests

-

Pulsed immunity

Pulsed immunity

-

Voltage dips and interrupts

Voltage dips and interrupts

-

-

-

A list of Technical Setup Files (TSF files) will be displayed. The test engineer can select one of these TSF files to load all parameters from a voltage dips and interrupts defined test or press cancel to define a new voltage dips and interrupts test.

After the TSF file has been selected, the voltage dips and interrupts configuration window will appear.

When a TSF file is loaded, all test parameters will be already configured and pressing the start button on the right side of the screen will start the test.

When a new TSF file is loaded (by pressing New in the TSF selection window) all parameters will be at zero and can be configured by the operator.

The picture below shows the voltage dips and interrupts test configuration screen.

The operator has to select cable to be tested (1 or 3 phase / DC / IO). The cable under test is part of the EUT so it needs to be configured in the EUT window under cables. Furthermore the operator has to configure the test level, polarity, phase and the internal resistor and capacitor of the generator. The measurement results can be recorded in the right side of the screen. For each injection mode, the operator can select pass or fail and make notes in the “notes” field. All configurations (except for the test results) can be stored in a TSF file.

| Selection of the mains cable on which this pulsed-immunity test will be applied. The cable is created and managed in the EUT window. |

| Defines how many times the complete test configuration is executed. |

| Defines the supply type for the sequence (AC or DC). |

| Nominal supply voltage applied to the EUT during the test. |

| Percentage of the rated voltage applied during the dip or interruption. |

| Allows selection of one or more fixed phase angles (0°, 90°, 180°, 270°) or randomized angle triggering. |

| Selection of the line on which the voltage dip or interruption is applied. |

| Selection of the output impedance level of the generator (Low or High). |

| Time required for the voltage to ramp down to the reduced level. |

| Duration for which the reduced voltage level is maintained. |

| Time required for the voltage to ramp back up to rated level. |

| Total time interval between successive pulses in the sequence. |

| Number of dips generated within this sequence. |

| How many times this timing sequence is executed within the selected sequence configuration. |

{{ScreenElementDescription|Pulse shape|

| Graphical representation of the pulse form, showing the timing of the drop, hold, and recovery of voltage during the dip/interrupt event. |

| Indicates whether the selected sequence has not been tested, passed, or failed. |

| Field where the test engineer can enter observations, deviations, or test-related remarks. |

| Selection of the equipment list to be used for this sequence. The list is defined and maintained in the equipment configuration. |

| Opens the equipment list for viewing or editing. |