Chapter 12

Calibration[edit]

During an (immunity) calibration, RadiMation® stores all settings and used equipment during the calibration in the final calibration (CAL) file. All these important settings (like start frequency, stop frequency, probe response time, frequency step size, calibration type (FWD, transmitted or signal generator level, etc.) are recorded.

Furthermore, the following graphs are stored:

- The achieved field strength (or current or voltage) during calibration.

- The signal generator level, necessary to achieve this field strength (or current or voltage level)

- The forward power, necessary to achieve this field strength (or current or voltage level)

- The transmitted power, necessary to achieve this field strength (or current or voltage level)

| Note: | When a signal level calibration is made and no power meters are used, the forward and reflected power graphs are not stored.

When a forward power calibration is made and no reflected power meter is used, the reflected power graph is not stored. |

All this information can later be viewed, reported, processed and printed by the end-user.

To view the results of a calibration, the calibration data can be opened from the menu:

-

File

File

-

Open

Open

-

Calibration

Calibration

-

-

-

Then the calibration data window is shown, and the configuration of the calibration, as well as the used equipment and the calibration data is displayed.

Frequency interpolation[edit]

RadiMation® allows you to use a frequency step size during a test, that is different than the frequency step size during the calibration. To have optimal results, RadiMation® will use a linear interpolation between the frequency point which is just below the desired test point and the frequency point which is directly above the test point, to correctly calculate the needed power values at the desired frequency. For the most accurate results it is however advised to perform the calibration in the same frequency range and frequency steps, as will be used during the test. RadiMation® will not (and cannot) allow that a test is performed on frequencies that is outside the calibrated frequency range.

Amplitude extrapolation[edit]

RadiMation® allows you to run a test at a different test level as used during the calibration. To facilitate this, RadiMation® will use a linear extrapolation from the calibration level to the desired level.

If, for example, at a certain frequency point 100 Watt (+50 dBm) is needed to generate a field of 10 V/m (which is determined during calibration), it is possible to use this calibration file to run a test at 3 V/m. RadiMation® will recalculate the needed power level to: 50 dBm - 20 log (10/3) = 40 dBm (10 Watt). Of coarse, amplitude extrapolation will reduce the accuracy of the test level and should therefore only be used during pre-compliance tests. For the most accurate results it is therefore advised to perform the calibration on the same test level, as will be used during the test.

| Warning: | The amplitude extrapolation will only be correct if the power amplifier works in its linear region. |

Calibration methods[edit]

RadiMation® supports three different ways of power calibration. During the configuration of the calibration, the desired method should be selected. During a test, when a calibration file is selected, RadiMation® will automatically select the method that was used during calibration.

Signal generator level calibration[edit]

When a signal generator level calibration is used, only the signal generator level is recorded during the calibration. During a test, the signal power that was recorded during a calibration will be re-established. This method does not take amplifier instability or fluctuation into account. During this calibration method no forward and reflected powermeters are required. This method is less accurate than the Forward power and Net power calibrations and therefore is not recommended for full compliance tests. Because no powermeters are used, this is method is the fastest method to perform a test.

Forward power calibration[edit]

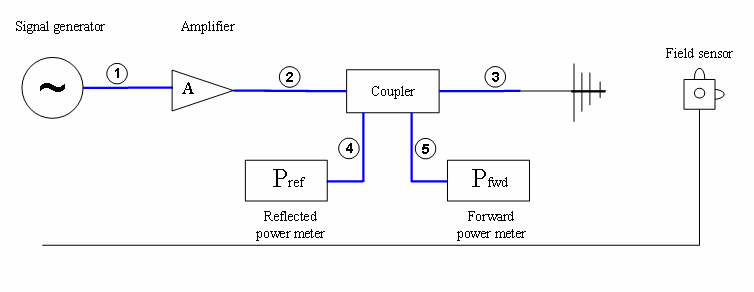

During a Forward power calibration, the forward power to the transmitting antenna is recorded. During a test, the Forward power to the antenna is kept the same as during the calibration. When this method is used, amplifier drift will have no influence on the test, because the same output power out out of the amplifier is re-established as was present during the calibration.

Net power calibration[edit]

During a Net power calibration, the Forward and Reflected power to the antenna are recorded. The difference between the Forward power and Reflected power is the Transmitted power. When net power is calibrated, then during the test, the transmitted power by the antenna is kept the same as during calibration. This method has the advantage, that the transmitted power is adjusted to be the same as during the calibration, also when a large metallic, EUT is placed in front of the antenna. In that situation some RF energy can be reflected back into the antenna, resulting in a worse VSWR. If in this situation a forward power calibration or a signal generator level calibration was used, this effect is not compensated for.

Radiated Immunity calibration[edit]

Calibration of the radiated immunity test set-up is necessary when tests in accordance to the substitution method are performed. During a calibration, the empty anechoic chamber is calibrated. During this calibration the power to the transmitting antenna is recorded, which is necessary to achieve the desired field strength in the anechoic chamber. During the substitution test, the EUT is placed inside the anechoic chamber, and the same power is applied to the transmitting antenna. With the same power applied to the transmitting antenna, it is assumed that the the EUT is located in an electrical field that is the approximately the same as during the calibration.

Some standards describe two different methods for the actual way of levelling to a required test-level. These methods are often called the: 'Constant field strength calibration method', and the 'Constant power calibration method'. During the one-point calibrations, RadiMation® will always use the 'constant field strength calibration method' that is described by the standards. This method has several advantages:

- Some fieldsensors have problems with their accuracy at the overlapping of their measurements ranges. To avoid these problems it is better to always level to the same field strength level, which will result in the usage of the same measurement range of the field sensor.

- With the constant field strength calibration method, it is more obvious if the required field strength level can be achieved. If the 'constant power calibration method' is used, there may be a big dip or peak in the calibration. This can result in interpolation errors. For example, a constant power calibration at 50 dBm can generate a field of 100 V/m at 100 MHz, and in the same calibration it is possible that a field of 80 V/m is generated at 800 MHz, due to the amplifier/powermeters/cables and couplers characteristics. If with these calibration results, a substitution is performed for a fixed field of 110 V/m, the error that is made as a result of the extrapolation from 100 V/m will be much smaller then from 80 V/m.

- The linearity error from the field sensor is much larger than the linearity error of the powermeter. When a 'constant field calibration method' is used, the error caused by the linearity of the fieldsensor is reduced to a minimum because the field sensor is always levelled to the same measurement value. The powermeter will perform measurements over a larger amplitude range, but the dynamic range of all powermeters is large enough to have a minimal linearity error. So when you the calibration is levelling on the field sensor, the linearity error of the calibration is minimal.

One-point calibration[edit]

During a one-point calibration, RadiMation® for each frequency point increases the power to the antenna, until the desired field strength is reached. Then, depending on the type of calibration method, RadiMation® records the Signal generator level, forward power and/or the transmitted power in the calibration file.

To start a one-point calibration, close all EUT windows. And select the one-point calibration from the menu:

-

Calibration

Calibration

-

Radiated Immunity

Radiated Immunity

-

1 Point Calibration

1 Point Calibration

-

-

-

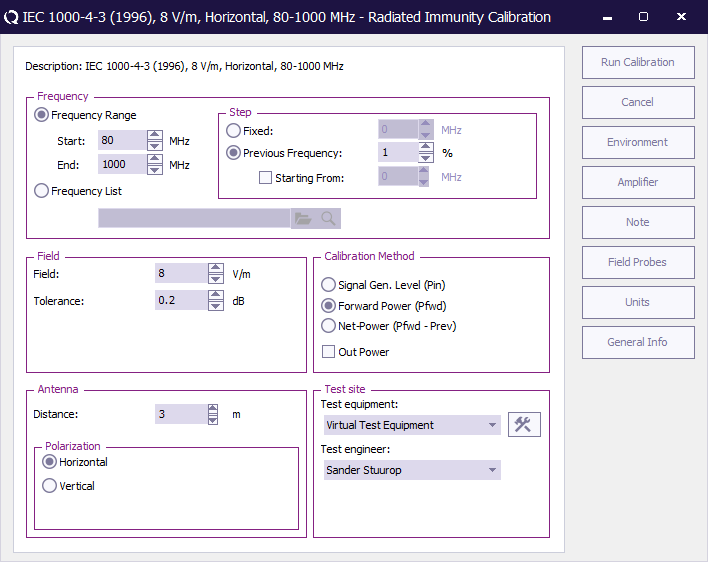

The Radiated Immunity calibration configuration window will appear, which allows modification of the settings for the calibration.

The one-point calibration is also able to perform a calibration of a triplate setup. The triplate calibration is required, to perform the triplate test. With the triplate calibration it is also possible to determine the impedance of the triplate, which is needed to calculate the field. The difference between a anechoic chamber calibration and a triplate calibration is the out power. To perform a triplate calibration the Net-power calibration method as well as the out-power method needs to be selected.

To define the fieldprobe position height during a triplate calibration, use the antenna distance. The selection of a polarization does not influence the triplate calibration, and it will thus be ignored.

| Device name | Tab in RadiMation®configuration window |

|---|---|

| Signal Generator | Standard 1 |

| Amplifier | Standard 1 |

| Coupler | Standard 1 |

| Power meter Pfwd | Standard 1 |

| Power meter Refl | Standard 1 |

| Antenna | Standard 1 |

| Field sensor | Field probes |

| # | Device name | Tab in RadiMation® configuration window |

|---|---|---|

| 1 | Sign-> Amp | Cables |

| 2 | Amp-> Coupler | Cables |

| 3 | Coup->Ant | Cables |

| 4 | Coup->Pfwd | Cables |

| 5 | Coup->Pref | Cables |

| Note: | Usage of cable correction factors is not mandatory. However, using correction factors will increase measurement accuracy during immunity measurements.

When in doubt contact your reseller. |

Uniform Field Area calculation[edit]

The EN 61000-4-3 (and other standards) state that the anechoic chamber must have a homogeneous field distribution in a 1.5 m x 1.5 m square area, 80 cm. above the ground.

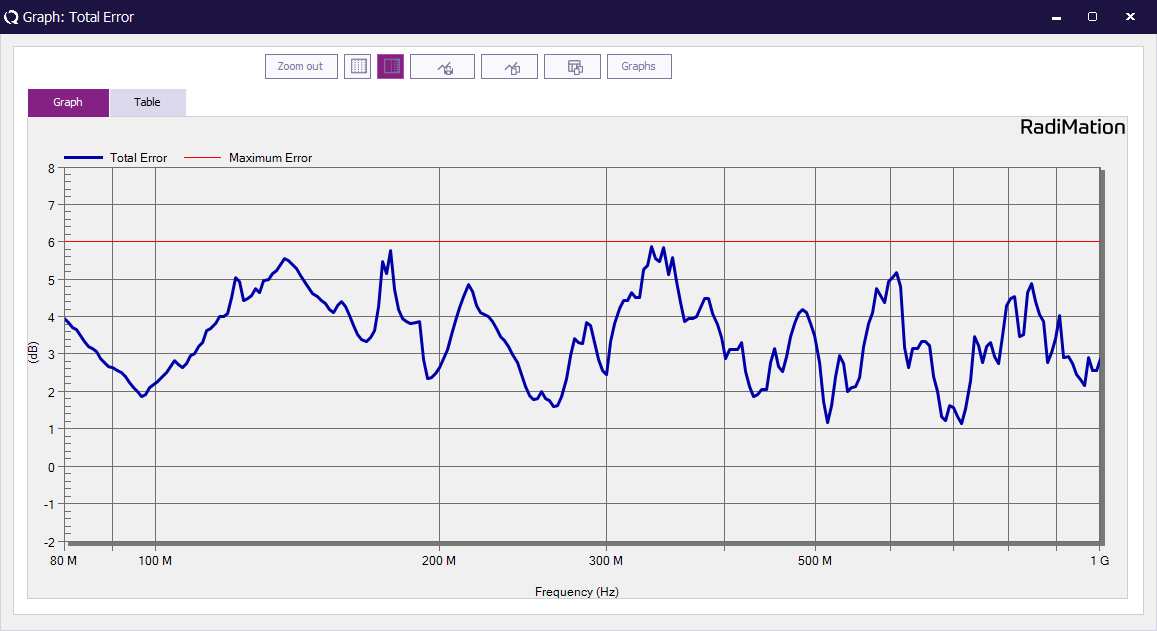

The field is defined as homogeneous if, at 12 of 16 points in the 1.5 m x 1.5 m square the field strength lies between the desired value and the desired value plus 6 dB (see the figure below).

If, for example, the field homogeneity check is made at a field strength of 10 V/m, 12 of the 16 points must lie between 10 V/m and 20 V/m.

Also based on this information, a power curve can be calculated, which can best be used during a substitution test, to achieve a homogeneous electrical field.

RadiMation® is able to verify and calculate the homogeneous field distribution in the 'Uniform Field Area calculation'. The input for this calculation are sixteen '1 point calibrations'. All these 16 single point calibrations, should be performed first, after which the 16 point field homogeneity verification software can be used to verify the field homogeneity in the anechoic chamber.

The 'Uniform Field Area calculation' is started by selecting from the menu:

-

Calibration

Calibration

-

System Calibration

System Calibration

-

Radiated immunity

Radiated immunity

-

Uniform Field Area calculation

Uniform Field Area calculation

-

-

-

-

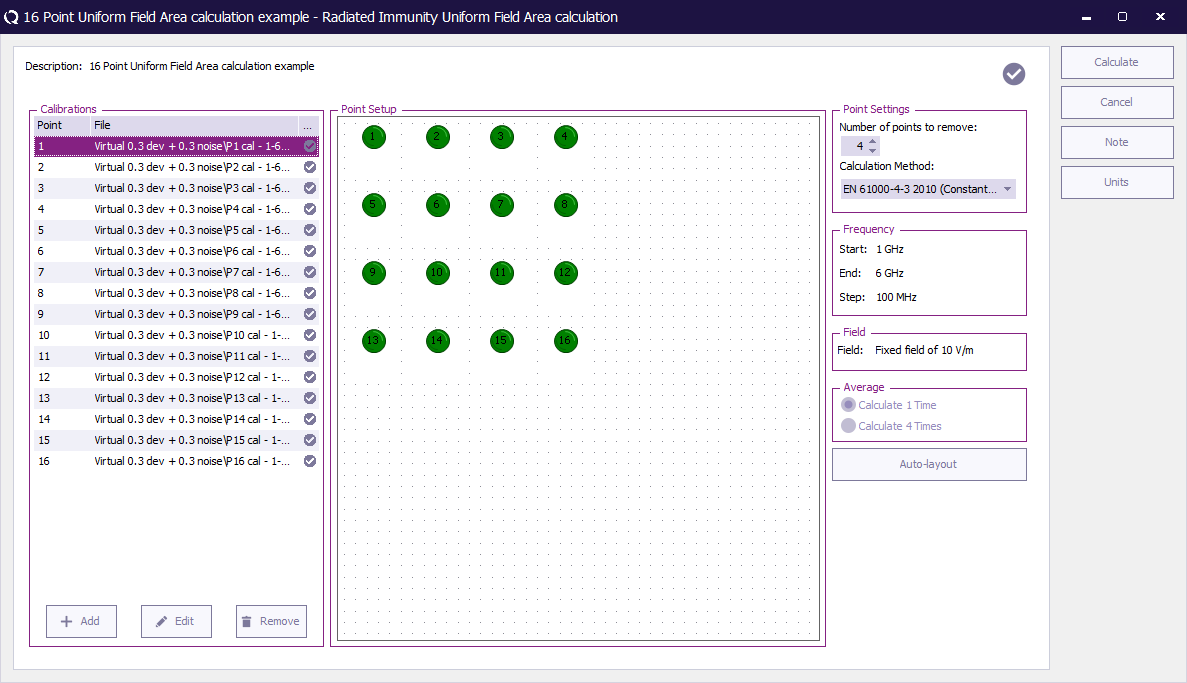

In the Uniform Field Area calculation, After a preconfigured Uniform Field Area calculation TSF file is selected, the configuration window of the calculation is shown.

The RadiMation® package supports different ways to calculate the homogeneity of a field, and some other settings can also be configured.

| The name of the selected TSF file |

| 16 different file selection boxes, where up to 16 single point calibration files can be selected. The correct calibration file can be selected by pressing on the File button behind the file selection box. |

| It is not required to use exactly 16 different calibration files in the calculation. All the calculations also support less then 16 calibration points. The Amount Of Points box, determines the number of calibration points that should be used during the calculation. |

| It is not required that always 4 calibration points are discarded during the calculation. The number in the Amount of Points To Remove box, determines the number of calibration points that will be discarded during the calculation. This number should be between 0 and the value that is specified in the Amount Of Points box |

The calculation method that should be used by the Uniform Field Area calculation, to calculate the homogeneity. The following methods are supported:

|

| Shows the start frequency of the selected calibration files. |

| Shows the end frequency of the selected calibration files. |

| Shows the step frequency that is used in the selected calibration files. |

| Shows the field strength level that was used in the selected calibration files. |

| During some calculations, the average field of the remaining calibration points is calculated, to determine the calibration point that should be discarded. When the Calculate 1 Time option is selected, the average field will not be recalculated when the calibration point is discarded. With this option activated, the calculation for each frequency point, will take the average field of all the calibration points once, and will determine the four calibration points which differ the most from the calculated average field. This option can result in a different calculation, compared to the Calculate 4 Times option. |

| During some calculations, the average field of the remaining calibration points is calculated, to determine the calibration point that should be discarded. When the Calculate 4 Times option is selected, the average field will be recalculated when a calibration point is discarded. A removal of a calibration point will influence the average field of the remaining points, and this can influence the calibration point that should discarded next. This option can result in a different calculation, compared to the Calculate 1 Time option. |

| Closes the configuration window, and starts the calculation of the homogeneity of the anechoic chamber, based on the selected calibration files and settings. |

| Closes the configuration window, and now calculation will be performed. |

| Shows the Note window, in which a Note can be specified. |

| Shows the Units window, where the used units can be configured. |

EN 61000-4-3 1995 calculation[edit]

EN 61000-4-3 2002 calculation[edit]

EN 61000-4-3 2002 Amendment 1 calculation[edit]

EN 61000-4-3 2006 calculation[edit]

ISO 11451-2 calculation[edit]

J1113-25 calculation[edit]

Uniform Field Area calculation results[edit]

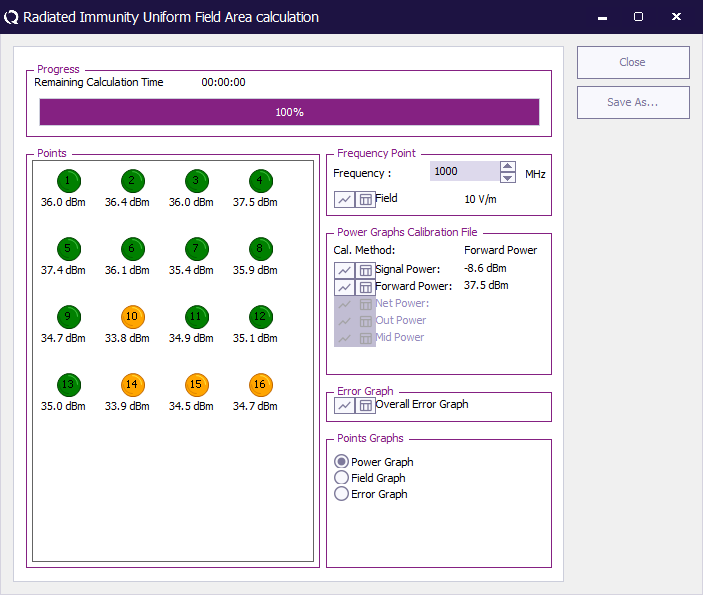

After RadiMation® has calculated the Uniform Field Area calculation, a graphical representation of the calibrations results will be displayed.

The graphical representation of the calculation is shown as 16 coloured dots on the screen. Each dot represents a calibration point in the anechoic chamber. The colours of the dots have the following meaning:

- Green dot: This calibration point is one of the remaining calibration points, which are taken into account for the calibration file.

- Yellow dot: This calibration point is one of the calibration points, which are discarded by the calculation. This calibration point is one of the Amount Of Points To Remove.

- Red dot: This calibration point was not discarded by the calculation, and is thus used in the final calculation of the needed power. However, it has an error of more than 6 dB compared to the ideal calculated power. This means that this calibration point does not meet the requirements for the field homogeneity in the anechoic chamber.

At the right side of the window, the test frequency can be adjusted. The dots will directly show the calculated information for the calibration points at the specified frequency.

In addition to the coloured dots, a large number of graphs and data-tables can also be reviewed:

| (only if the forward or net power calibration method is used). |

| (only if the net power calibration method is used). |

{{ScreenElementDescription|Overall error graph| (to verify if 12 of the 16 points lie within the 6 dB error)

For each coloured dot, also a graph can be shown, which shows the relevant information for that specific calibration point. These graphs can be shown by clicking on one of the dots. Depending on the selected Power Graph, Field Graph or Error Graph option, the corresponding graph will be shown.

- Power Graph: Shows the power that is used to achieve the desired electrical field strength level during the calibration of the calibration point. This graph is corrected for the error and tolerance that occurred during the calibration. If the calibration is made at a test level of 10 V/m with an tolerance of 1 V/m, the Uniform Field Area calculation will more accurately determine the power that is needed to exactly achieve 10 V/m (even if the calibration is made at for example 10.4 V/m).

- Field Graph: When the final calibration file is used in a substitution test, the Field graph displays the calculated field that will be generated at the selected calibration point.

- Error Graph: The Error Graph display the error for the selected calibration point, which is the difference between the power level on the selected calibration point, and the most ideal calibration point. On frequencies where the calibration point was discarded during the Uniform Field Area calculation, the graph will show a 0 dB error value.

Merge five one point calibration into one final calibration[edit]

To merge the five calibrations into one, select the 16-point calibration.

-

Calibration

Calibration

-

Radiated Immunity

Radiated Immunity

-

16 Point Calibration

16 Point Calibration

-

-

-

In the following screen select the five one-point calibration files you want to merge, after that select determine Z.

Select calculate to start the calculation, when the calculation is done save the information and you can perform a triplate test.

The following formulas are used to determine the impedance of the triplate

Formula 12-1: Impedance

Formula 12-2: Middle power calculation

Calibration information that is stored after verification[edit]

Now that RadiMation® has determined the homogeneity, what is the information that is stored in the calibration file? And why? The method below describes for the signal generator level but also applies for the forward power and the net power calibration.

The software has determined the remaining 12 points for each frequency according to the chapter '16 point field homogeneity verification'.

With only 1 signal generator at hand its impossible to set all the 12 levels. So you would say take the average of all the levels and you are done. This would be right for about 50% of the verifications. But with a simple example it can be proven that this is not the right method.

Suppose you have the following 12 points left at 100 MHz:

| Point | Signal level (dBm) |

|---|---|

| 1 | -10 |

| 2 | -10 |

| 3 | -8 |

| 4 | -12 |

| 5 | -8 |

| 6 | -12 |

| 7 | -8 |

| 8 | -12 |

| 9 | -11 |

| 10 | -9 |

| 11 | -13 |

| 12 | -7 |

The average will give –10 dBm.

This means that with points 3,5,7,10 and 12 you are not generating enough power, because for these points you need a higher signal level. Worst case (number 12), you will generate only around 7 V/m instead of 10 V/m.

A better way is to use the highest value. When you perform a substitution with the highest level you can be 100% that the field is at least 10 V/m at 12 of the 16 points.

That is why RadiMation® saves the highest level in the calibration file.

Conducted immunity calibration[edit]

Calibration methods[edit]

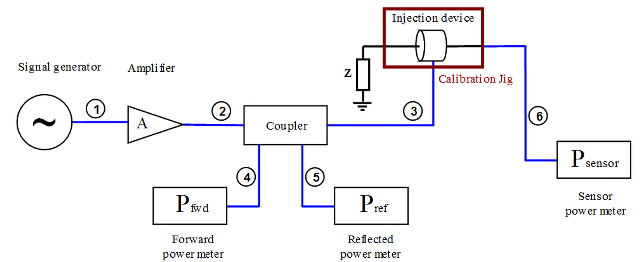

Calibration of the conducted immunity test set-up is necessary when tests in accordance with the substitution method are performed. During the calibration, the current in a reference wire is determined, and the power to the injection device is recorded.

During the test, the injecting device is connected to a cable of the EUT and the same power is injected into the cable by the usage of the injection device.

Voltage calibration[edit]

Calibration procedure:

The IEC 1000-4-6 is based on an EUT cable impedance of 150 Ω. To calibrate the test system, a cable with a characteristic impedance of 150 Ω is used. This reference cable is placed in the injection clamp. The left side of this cable is terminated through a 150 Ω terminator resistor. The right side of the cable is terminated with a 100 Ω resistor in series with a 50 Ω power meter. The measured power in the 50 Ω powerhead can be used to calculate the RF current in the 150 Ω reference wire.

The test level [Urms], as described in the IEC 1000-4-6 is the output voltage of a terminated generator (or amplifier).

If an amplifier with a 50 Ω output impedance is used in conjunction with a injection clamp with a 50 Ω input impedance, the voltage applied to the input of the injection clamp will be [Urms/2].

The current injected in a 150 Ω wire will be [Urms/2] / 150 Ω.

By measuring the voltage across the 50 Ω powerhead, the calibration software determines the signal generator level which generates the desired current in the reference cable.

Formula 12-3: Expected powermeter reading

Example:

Test level according to IEC 1000-4-6: 10 Vrms (140 dBuV) Measured value (U powerhead): 140 dBuV - 15,6 dB = 124 dBuV or = 17 dBm (in a 50 Ω system)

The calibration is carried out with an unmodulated test signal.

| Device name | Tab in RadiMation® configuration window |

|---|---|

| Signal Generator | Standard 1 |

| Amplifier | Standard 1 |

| Coupler | Standard 1 |

| Power meter Pfwd | Standard 1 |

| Power meter Refl | Standard 1 |

| Injection device | Standard 2 |

| Calibration Jig | Standard 2 |

| Sensor power meter | Standard 2 |

| # | Device name | Tab in RadiMation® configuration window |

|---|---|---|

| 1 | Sign-> Amp | Cables |

| 2 | Amp-> Coupler | Cables |

| 3 | Coup->Ant | Cables |

| 4 | Coup->Pfwd | Cables |

| 5 | Coup->Pref | Cables |

| 6 | Curr->Sens | Cables |

| Note: | Usage of cable correction factors is not mandatory. However, using correction factors will increase measurement accuracy during immunity measurements.

When in doubt contact your reseller. |

Current calibration[edit]

Verification procedure:

After a calibration has been carried out, the calibrated test set-up can be checked by the following procedure. The same set-up is made as during calibration. As an extra check, a measuring current probe is placed around the 150 Ω reference wire. After the calibration has been completed, a radiated immune, substitution test is made with a test level of 10 Vrms.

The theoretical current with a test level of 10 Vrms will be: (Urms/2) / 150 = 33 mA

When a current probe with an transfer impedance of 1 Ω is used, a voltage of 33 mV should be measured (or approximately 90 dBuV).

System Calibration[edit]

System calibrations are performed on a test setup, before the test setup can be used to perform the actual calibration on a device that should be calibrated. Some examples of supported (system) calibrations are:

- Attenuation measurements of cables, couplers or other attenuators.

- 1-16 point calibration of anechoic chamber before a radiated immunity test can be performed.

- Calibration of conducted immunity setup before a conducted immunity test can be performed.

- Open/Short/Through calibration of network analyzer before S-parameter measurement can be performed.

Attenuation system calibration[edit]

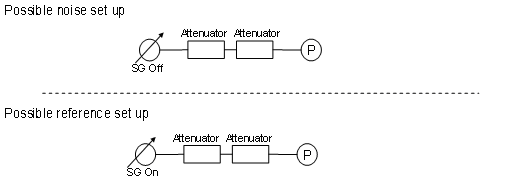

During the system calibration for the attenuation the complete set up is connected but without the EUT.

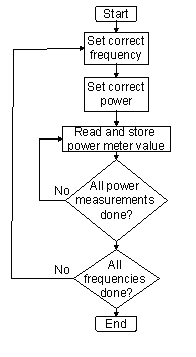

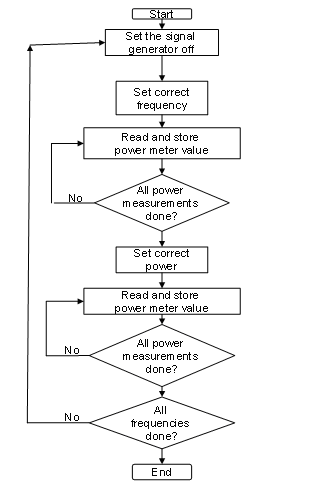

During the system calibration the signal generator is turned on and off at each frequency to determine the dynamic range at that certain frequency. The flow chart below describes the system calibration. The routine has been optimized for the least amount of power switching. The system calibration for attenuation is performed in two steps:

- The frequency response of the signal generator and power meter is determined. The measurement response is used as a correction for the actual attenuation calibration of the d.u.t. during the attenuator calibrations.

- The dynamic range of the test setup is determined. This is done by switching of the signal generator and measuring of the noise floor.

The dynamic range is the difference between the measured power when the signal generator is on and when the signal generator is off.

Formula 12-4: Dynamic range

System calibration set up

Before starting a system calibration, make sure all the EUT windows are closed. The configuration window of a system calibration can be opened by selecting from the menu:

-

Calibration

Calibration

-

System Calibration

System Calibration

-

Attenuation / Gain

Attenuation / Gain

-

-

-

In the configuration window you can define the amount of sample that should be taken. The fastest way is one sample but this will disable the calculation of the standard deviation.

Power meter setting[edit]

For every frequency the average of all the samples is taken using the formula below

Formula 12-5: Average power calculation

As can be seen the average of the power measurement is taken over the linear value.

| Note: | The power measurement settings done in the device driver configuration screen are the settings for one sample. This is done because each power meter has a different leveling and measuring time. For the most optimal settings look at the device driver chapter for explanation and tips. |

Signal power setting[edit]

The signal generator level is set for the complete frequency range, this is desirable because it gives you full control. For example you can set the signal generator level higher when the dynamic range is insufficient, or lower when using a small amplifier.

Reviewing measurement data[edit]

During and after the test it is possible to view graphs by pressing the graph buttons.

In the graph window additional graphs for the related information can be added to the graphs. If the system calibration is configured to use multiple samples of the powermeter, the standard deviation of the following items is calculated:

- Dynamic range

- Reference attenuation

- Reference noise floor

Calculation of the standard deviation is done by using the formula:.

Formula 12-6: Standard deviation

The standard deviation for the dynamic range is calculated using the formula:

Formula 12-7: Standard deviation of the dynamic range

System Compression Calibration[edit]

The goal of the system compression calibration is to increase the accuracy of the measurement. It is possible to perform the EUT compression calibration without a system calibration but this will may have a measurement error in the number of 0.3 or 0.4 dB. This error comes from the difference between the signal generator and the power meter. Also attenuator clicks in the signal generator are not corrected. In the ideal situation there is no need for a System calibration.

The general thought behind the calibration is, the signal generator nor the power meter are exactly correct for every frequency and every power level. The signal generator has attenuator switches that can cause an error and the power meter has power ranges that can cause an error. Because this is a relative measurement, the power meter is defined to be infinitely accurate. The software records the difference between the signal generator and the power meter, measured with the new “accurate” power meter.

| Note: | Setting the power meter to be infinitely accurate is only valid in a relative measurement. The error caused by the power meter and the signal generator are corrected in the signal generator. |

To open the configuration window of a system calibration select. Before starting a calibration of a system make sure all the EUT windows are closed.

-

Calibration

Calibration

-

System Calibration

System Calibration

-

Gain Compression

Gain Compression

-

-

-

In the configuration window you can define the amount of sample you want to take. The fastest way is one sample but this will leave the possibility for standard deviation calculation out.

Power meter setting[edit]

For every frequency the average of all the samples is taken using the formula below

Formula 12-8: Average power calculation

As you can see the average is taken over the linear power value.

| Note: | The power measurement settings done in the device driver configuration screen are the settings for one sample. This is done because each power meter has a different leveling and measuring time. For the most optimal settings look at the device driver chapter for explanation and tips. |

Signal power setting[edit]

The signal generator level is set for the complete frequency range, this is desirable because it gives you full control. For example you can set the signal generator level higher when the dynamic range is insufficient, or lower when using a small amplifier.

| Note: | When inserting the calibration in the EUT compression configuration the same test levels are used. It is not possible to change the value, so select the settings with care. |

EUT Calibration[edit]

EUT calibrations are performed on devices that are considered to be an EUT. For example, during an attenuation calibration, the attenuation of an attenuator, cable or coupler can be measured.

EUT Attenuation Calibration[edit]

During an attenuation calibration, the attenuation of an attenuator, cable or coupler can be measured. It is also possible to use the calibration to determine the gain of an amplifier. The attenuation will in this case have a negative value.

EUT Attenuation Calibration[edit]

Before an EUT calibration can be performed, the calibration system first needs to be calibrated using a system calibration. After calibrating the EUT there is a possibility to save the measured attenuation into a correction file.

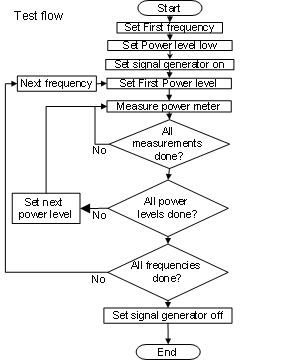

The flowchart below describes the testing procedure used for EUT calibration.

EUT calibration set up[edit]

To open the configuration of a calibration, as shown below, make sure the correct EUT window is open. Then select from the menu:

-

Calibration

Calibration

-

E.U.T. Calibration

E.U.T. Calibration

-

Attenuation / Gain

Attenuation / Gain

-

-

-

Select the correct calibration file and all the other setting will automatically be set.

The EUT calibration is performed with the same configuration settings as the configuration of the system calibration that was selected. This will ensure the lowest error, and the highest accuracy during the calibration:

- There is no interpolation error possible between frequency points.

- The calibration is performed at the same signal generator level preventing extra amplitude errors.

- Error budget calculation is possible

Reviewing measurement data[edit]

In the EUT calibration the standard deviation of the following items are calculated:

- Dynamic range

- EUT attenuation

For the dynamic range the standard deviation is calculated with the formula below

Formula 12-9: Standard deviation of the dynamic range

For the attenuation the standard deviation is calculated with the formula below

Formula 12-10: Standard deviation of the attenuation

In the information screen you can create a correction file for the attenuation measured. After pressing the “Create correction file” button a save dialog will appear, allowing you to select the desired path and filename for the correction file. This correction file can be attached to the calibrated device. For example, when the frequency response of a cable is measured, the correction file can be attached to the cable device driver, in the configuration menu of the cable.

EUT Compression Calibration[edit]

EUT compression calibrations are performed on amplifiers that are considered to be an EUT. The goal of this calibration is to determine the 1 dB or 2 dB compression point. The calibration also allows to calibrate any other compression point, because the required compression levels can be configured in the calibration. It is thus also possible to measure for example the 1 dB and the 3 dB compression points during a single calibration.

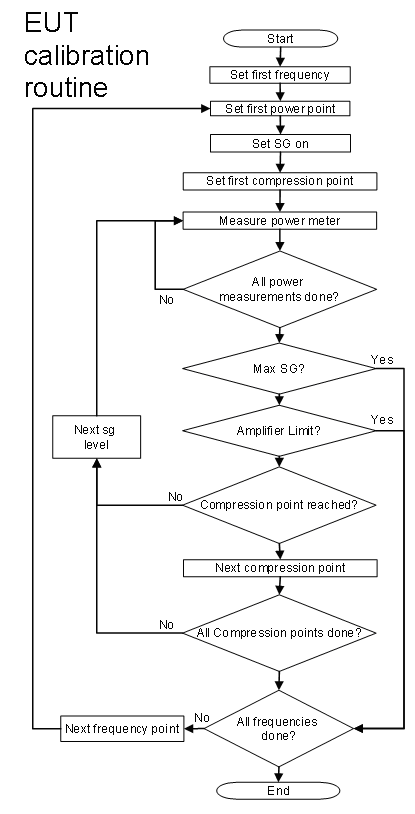

Before a EUT calibration can be performed, it is best to first perform the system calibration. This will decrease the overall error, which is depending on the devices you are using. The flowchart below describes the testing procedure used for EUT calibration.

EUT calibration set up[edit]

To open the configuration of a calibration, open as showed below, make sure the correct EUT window is open, and then select from the menu:

-

Calibration

Calibration

-

E.U.T. Calibration

E.U.T. Calibration

-

Gain Compression

Gain Compression

-

-

-

Select the correct calibration file, and all the other setting will automatically be set.

The EUT calibration is performed with the same configuration settings as the system settings. This is done to insure the lowest error.

- There is no interpolation error possible between frequency points.

- The calibration is performed at the same signal generator level preventing extra amplitude errors.

- Error budget calculation is possible

When no calibration file has been selected the settings can be set as desired.

Calibration of an amplifier can result in damaging the amplifier itself! We therefore suggest the following security precautions, during these type of calibrations:

- Signal power amplifier protection} should be set high enough for testing. The maximum input level is default 0 dBm when no correction file is attached to the amplifier. With a correction file the maximum input can be set higher then 0 dBm.

- Forward power amplifier protection should be used when the amplifier has an output power protection. The fail safe option is setting the limitation to the maximum and decrees this with one step size of the test. For example the limitation is set on 56,5 dBm (450 Watt) and the step size is 0.3 dB, than the limitation should be set on 56,2 dBm (420 Watt). This way the changes of the amplifier turning off during testing will become significantly smaller.

- Start level of the signal generator should be set on 20 dB lower then the lowest point specified by the manufacturer.

- Stop level of the signal generator should be the maximum input of the amplifier, most of the times this level will not be reached.

| Note: | Please note that these settings are guidelines, en should be treated as such. |

Reviewing measurement data[edit]

In the EUT calibration the standard deviation of the following items are calculated:

- Small signal gain power

- Compression points power

![{\displaystyle Z(f)=h^{2}*{\frac {{E_{avg}}^{2}(f)}{P_{mid}(f)}}[\Omega ]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/77937bcf79ab8784aa7ce128a92618cabf948318)

![{\displaystyle P_{mid}(f)={\frac {P_{net}(f)[W]+P_{out}(f)[W]}{2}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/314e7cd0304dcce9e77cbd855c5c08b1d46f04a2)

![{\displaystyle U_{powerhead}=U_{rms}-6[dB]-20*^{10}Log{\frac {50}{150}}=U_{rms}-15,6[dB]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/48a0719a6713ee6616a5a5d6d6201230c50ec154)

![{\displaystyle Dynamic\ rang[dB]=P_{on}[dBm]-P_{off}[dBm]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/1b09e0525b524537b221b69dd0f40b4deddbcd51)

![{\displaystyle P_{Power\ Measurement}(f)[dBm]=10*^{10}log({\frac {\sum _{N}^{i=1}10^{\frac {P_{powermeter(f,i)[dBm]}}{10}}}{N}})}](https://wikimedia.org/api/rest_v1/media/math/render/svg/1ae125e050da43e4242321851eadbf9719fcd4c8)

![{\displaystyle P_{power\ measurement}(f)[dBm]=10*^{10}log({\frac {\sum _{i=1}^{N}10^{\frac {P_{powermeter}(f,i)[dBm]}{10}}}{N}})}](https://wikimedia.org/api/rest_v1/media/math/render/svg/31845b9f62f4e66ba8e1067e5331fcdab878422e)