How to perform a MIL-STD CS114, Conducted susceptibility, bulk cable injection test[edit]

This application note explains how the MIL-STD CS114, Conducted susceptibility, bulk cable injection test can be performed with RadiMation®

The exact requirements and test methods for the CS114 are specified in the MIL-STD-461.

Necessary equipment[edit]

The following devices are necessary to run this test:

- Signal generator

- Amplifier

- Coupler

- Forward power meter

- Reflected power meter (optionally)

- Current sensor

- Sensor power meter / Analyser

- 50 Ohm load

- 50 Ohm attenuator

- LISN

- Current injection device

- Current injection calibration jig (Calibration fixture)

- Cable drivers with corrections

Configuration of the test sites[edit]

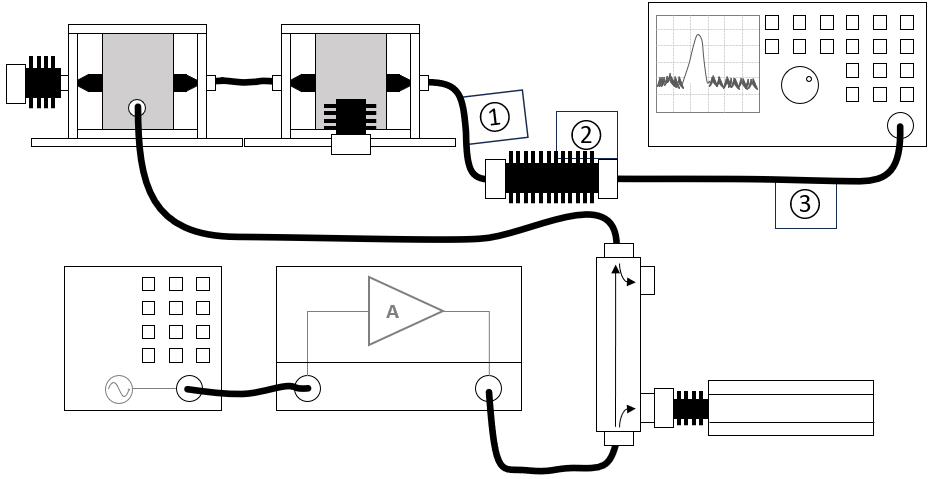

Calibration[edit]

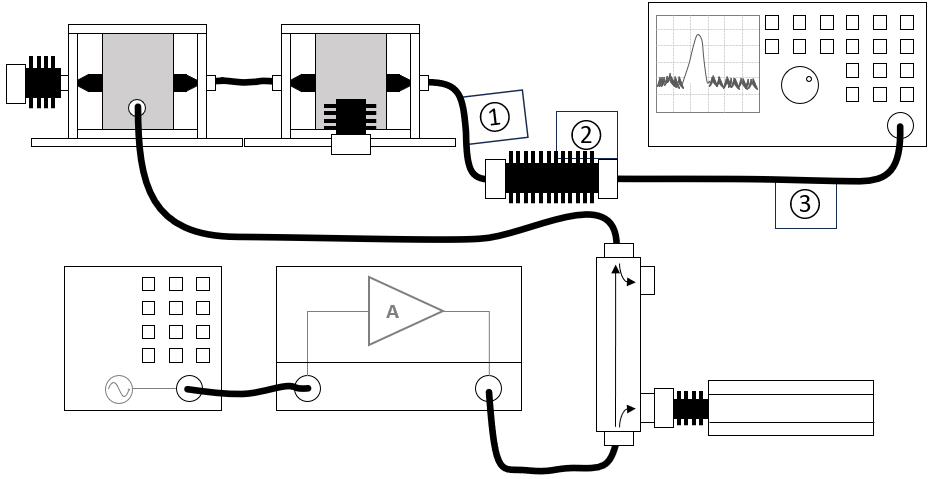

The configuration of the calibration test site should contain the following devices:

| Device name |

Tab in testsite configuration window |

note

|

| Signal generator |

Devices 1 |

The signal generator to use

|

| Amplifier |

Devices 1 |

The amplifier to use

|

| Coupler |

Devices 1 |

The coupler to use

|

| Forward power meter |

Devices 1 |

The forward power meter to use

|

| Reflected power meter |

Devices 1 |

The reflected power meter to use (optionally)

|

| Sensor power meter |

Devices 2 |

The power meter or analyser to use for measuring the current

|

| Current sensor |

Devices 2 |

The current sensor to use with transfer factor attached to the driver

|

| Injection device |

Devices 2 |

The injection clamp to use

|

| Jig |

Devices 2 |

The jig to use

|

| Cable current -> power meter |

Cables |

Cable (1) with a correction file specified for the cable loss

|

| Cable current -> power meter |

Cables |

Cable (2) with the specified loss of the used attenuator

|

| Cable current -> power meter |

Cables |

Cable (3) with a correction file specified for the cable loss

|

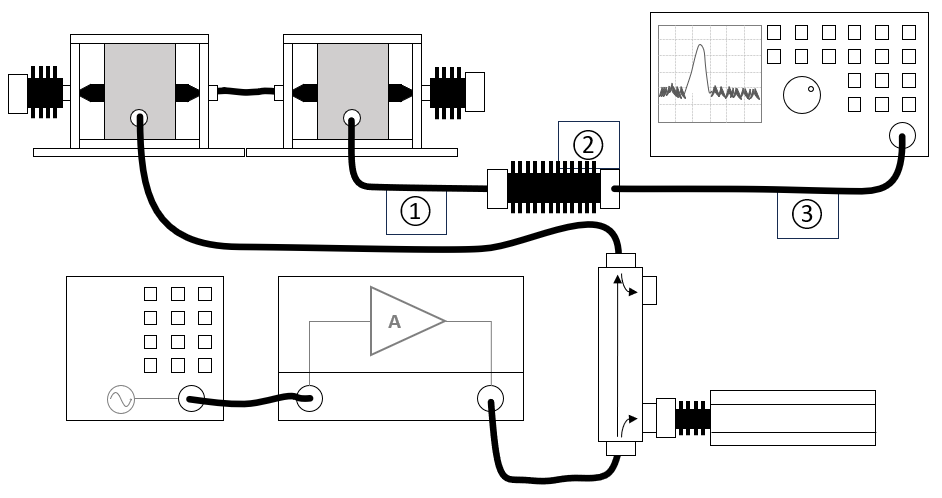

Verification[edit]

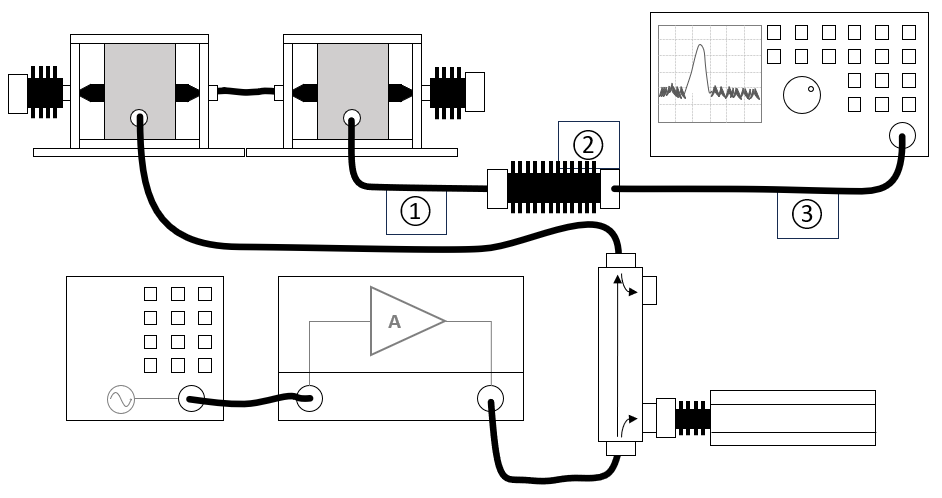

The configuration of the verification test site should contain the following devices:

| Device name |

Tab in testsite configuration window |

note

|

| Signal generator |

Devices 1 |

The signal generator to use

|

| Amplifier |

Devices 1 |

The amplifier to use

|

| Coupler |

Devices 1 |

The coupler to use

|

| Forward power meter |

Devices 1 |

The forward power meter to use

|

| Reflected power meter |

Devices 1 |

The reflected power meter to use (optionally)

|

| Sensor power meter |

Devices 2 |

The power meter or analyser to use for measuring the current

|

| Current sensor |

Devices 2 |

The current sensor to use with transfer factor attached to the driver

|

| Injection device |

Devices 2 |

The injection clamp to use

|

| Cable current -> power meter |

Cables |

Cable (1) with a correction file specified for the cable loss

|

| Cable current -> power meter |

Cables |

Cable (2) with the specified loss of the used attenuator

|

| Cable current -> power meter |

Cables |

Cable (3) with a correction file specified for the cable loss

|

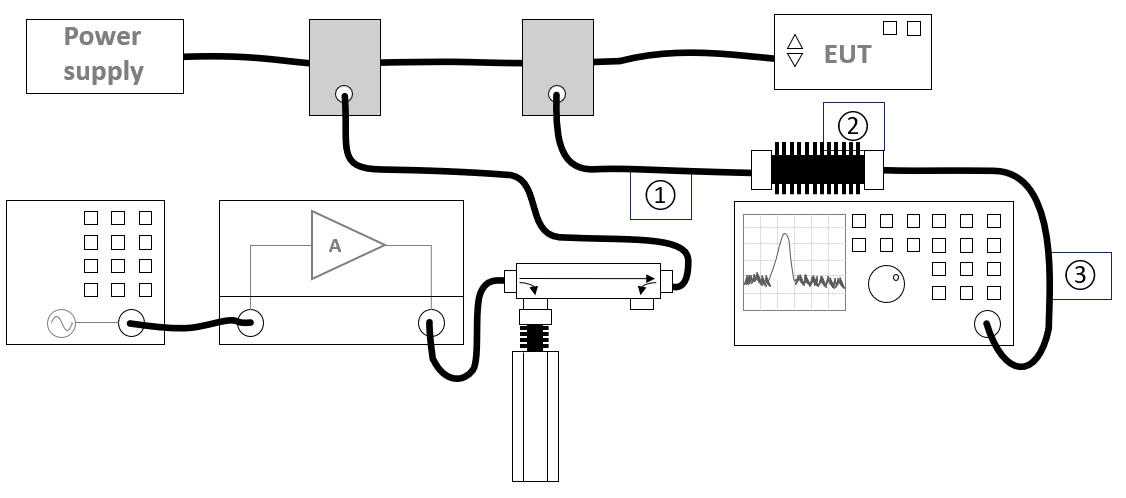

EUT Testing[edit]

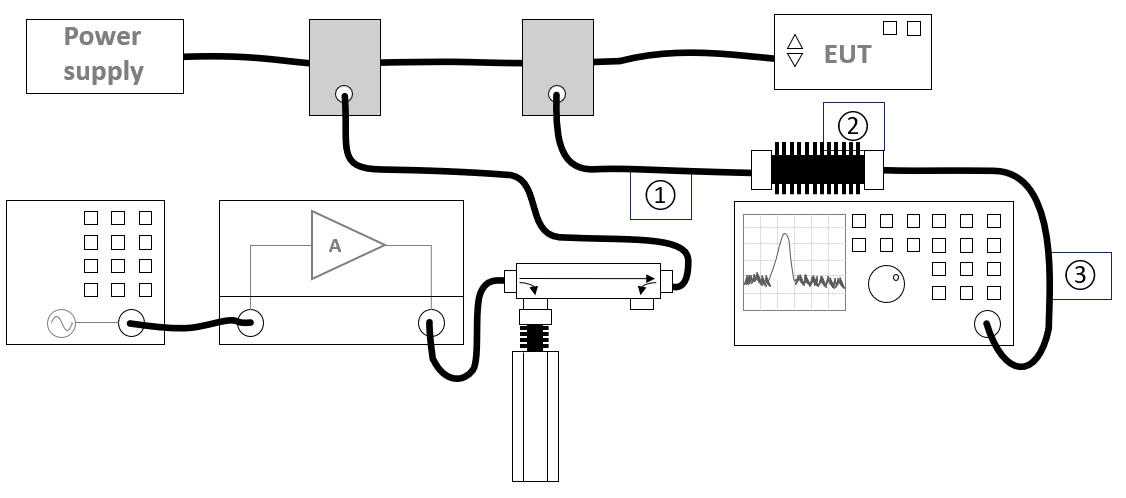

The configuration of the eut test site should contain the following devices:

| Device name |

Tab in testsite configuration window |

note

|

| Signal generator |

Devices 1 |

The signal generator to use

|

| Amplifier |

Devices 1 |

The amplifier to use

|

| Coupler |

Devices 1 |

The coupler to use

|

| Forward power meter |

Devices 1 |

The forward power meter to use

|

| Reflected power meter |

Devices 1 |

The reflected power meter to use (optionally)

|

| Sensor power meter |

Devices 2 |

The power meter or analyser to use for measuring the current

|

| Current sensor |

Devices 2 |

The current sensor to use with transfer factor attached to the driver

|

| Injection device |

Devices 2 |

The injection clamp to use

|

| Cable current -> power meter |

Cables |

Cable (1) with a correction file specified for the cable loss

|

| Cable current -> power meter |

Cables |

Cable (2) with the specified loss of the used attenuator

|

| Cable current -> power meter |

Cables |

Cable (3) with a correction file specified for the cable loss

|

Calibration procedure[edit]

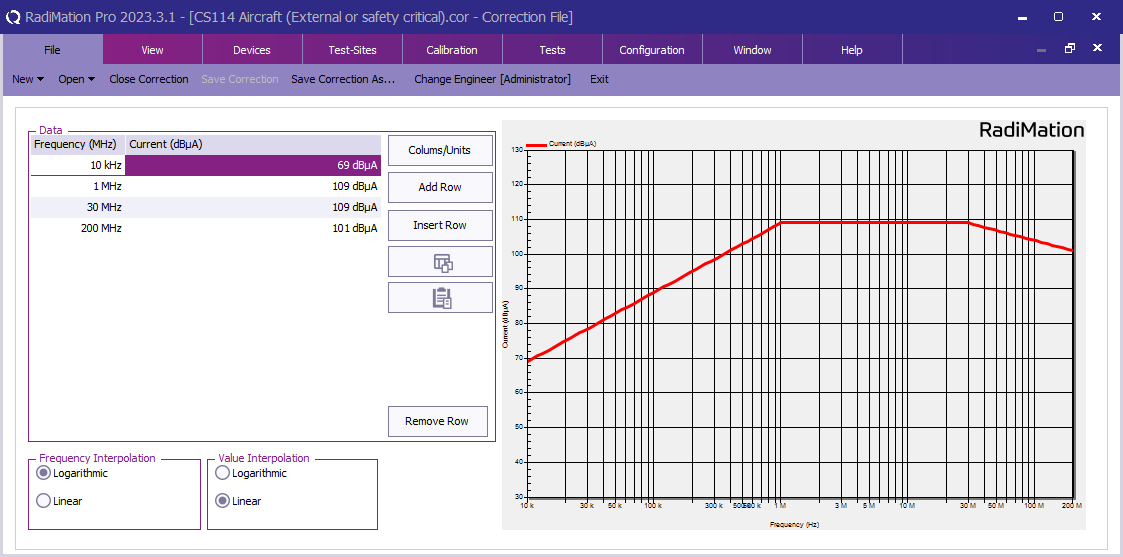

Create a correction file for the test level[edit]

-

File

File

-

New

New

-

Correction

Correction

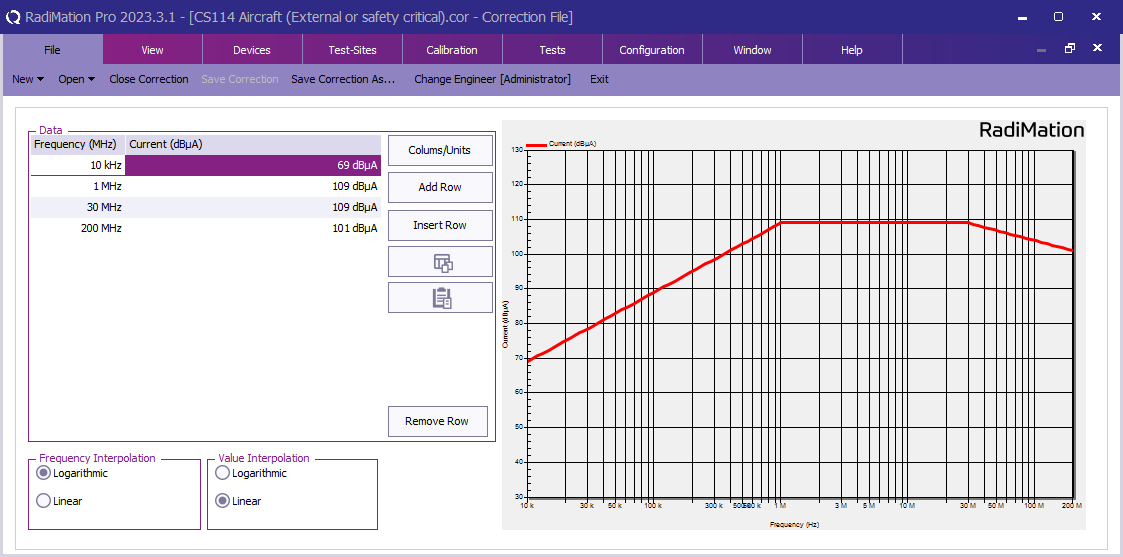

First create a correction file in RadiMation® and specify the applicable test level (See 'TABLE IV CS114 limit curves.' and 'FIGURE CS114-1. CS114 calibration limits.').

In this example the limits for 'Aircraft (External or safety critcal) / Curve 5 are configured.

Make sure to remove the Correction column and add the Current column with the unit set to dBuV.

Create calibration test setup files[edit]

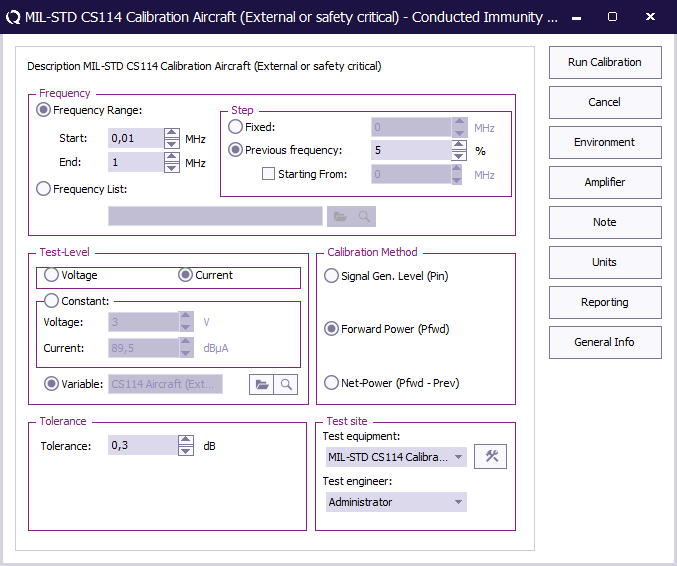

There are three frequency ranges that have to be calibrated with the following settings (see TABLE III).

| Band |

Frequency range |

Step size

|

| Band 1 |

10 kHz - 1 MHz |

5 %

|

| Band 2 |

1 MHz - 30 MHz |

1 %

|

| Band 2 |

30 MHz - 200 MHz |

0.5 %

|

-

Calibration

Calibration

-

System calibration

System calibration

-

Conducted immunity

Conducted immunity

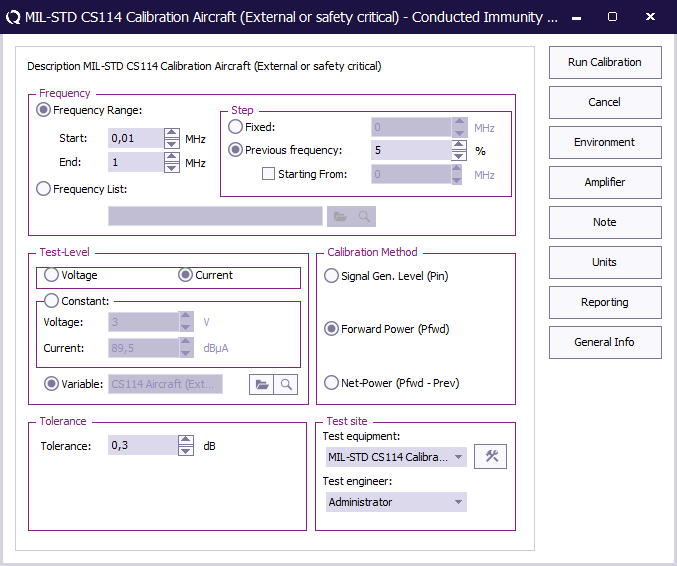

Create three test setup files, this example shows the settings for band 1.

Start Start

|

The start frequency of the test. For example 10 kHz.

|

End End

|

The stop frequency of the test. For example 1 MHz.

|

Step Step

|

The frequency step, in this case 5%.

|

Test level Test level

|

The test level, in this case current.

|

Variable Variable

|

The variable test level, select the correction file created earlier.

|

Tolerance Tolerance

|

The regulation tolerance.

|

Calibration method Calibration method

|

Forward power.

|

Test equipment Test equipment

|

Calibration test equipment.

|

Test engineer Test engineer

|

The engineer that performed the calibration.

|

Calibration result[edit]

When the three calibrations are performed there should be three calibration files created.

Verification[edit]

Create the Test Setup File (TSF)[edit]

CS114 requires to perform a verification of the setup with the probes in the calibration setup. With this verification it is important to verify that the forward power of the calibration is followed and that the developed current is within 3 dB tolerance of the current test limit.

-

Tests

Tests

-

Conducted Immunity

Conducted Immunity

-

Multiband

Multiband

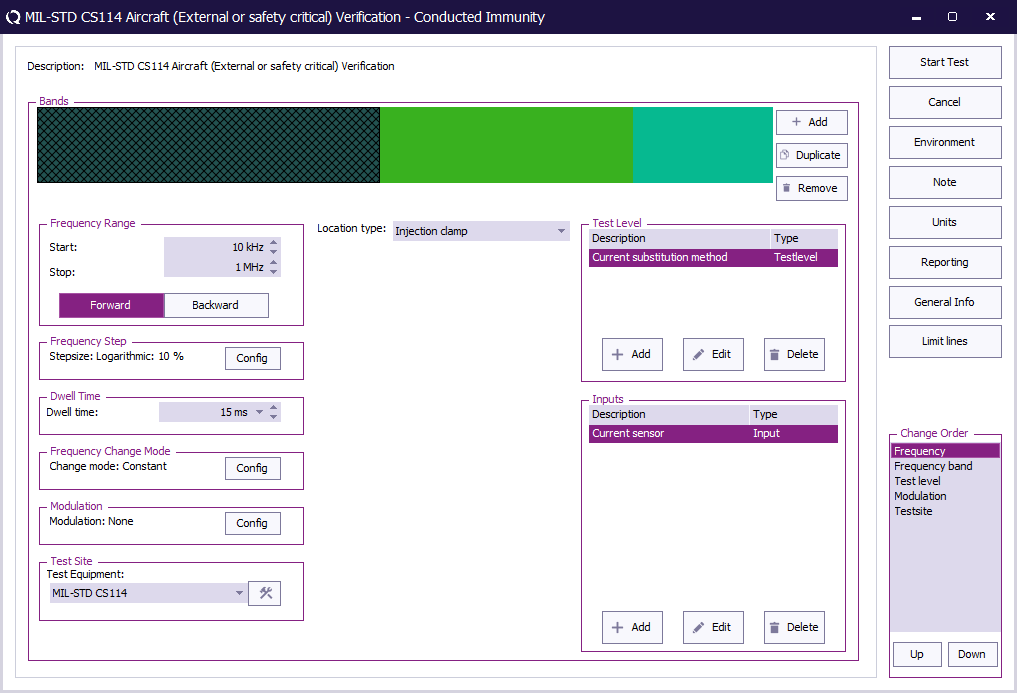

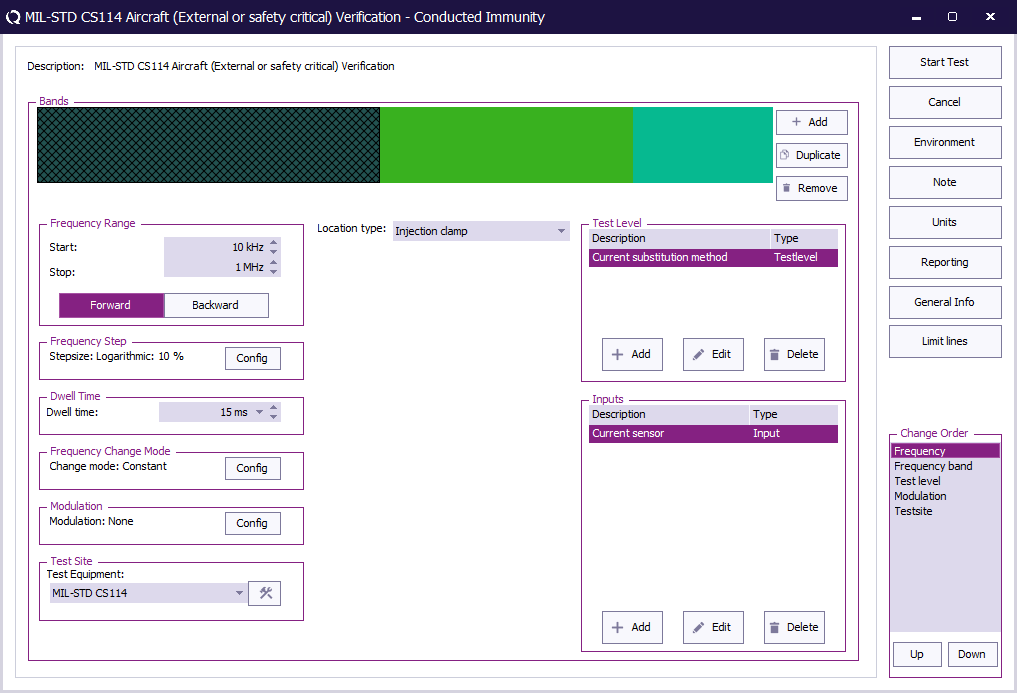

Create a new multi band conducted immunity test and define three bands with the following settings:

| Band |

Frequency range |

Step size

|

| Band 1 |

10 kHz - 1 MHz |

10 %

|

| Band 2 |

1 MHz - 30 MHz |

2 %

|

| Band 2 |

30 MHz - 200 MHz |

1 %

|

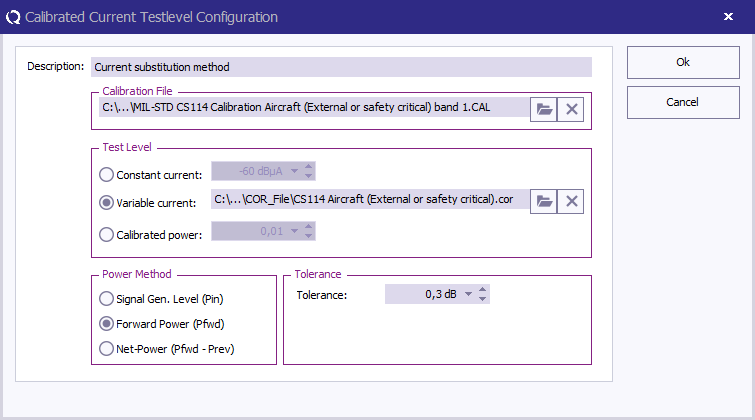

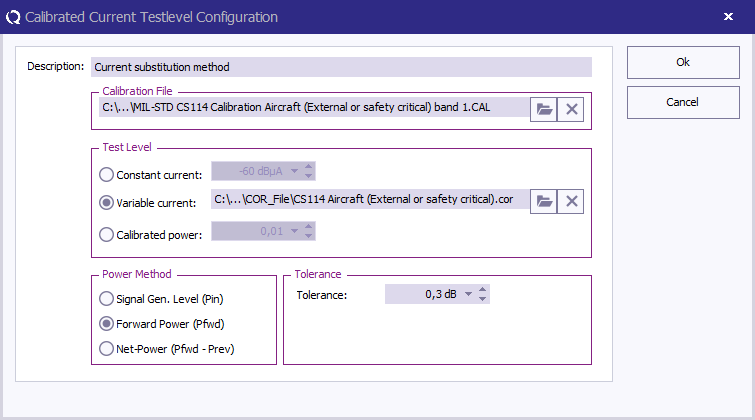

Each band needs a test level defined with the test level "Current substitution method" and the appropriate calibration file attached.

Make sure to select the same "Power Method" as done during the calibration, in this case "Forward Power".

Next to the test level add an input "Current sensor", this will ensure that the current is measured during the test.

Start Start

|

The start frequency of the test. For example 10 kHz.

|

End End

|

The stop frequency of the test. For example 1 MHz.

|

Frequency Step Frequency Step

|

The frequency step, see 5.12.3.4.c.3.

|

Dwell Time Dwell Time

|

The dwell time specified see TABLE II.

|

Frequency Change Mode Frequency Change Mode

|

Constant.

|

Modulation Modulation

|

Modulation is optional during the verification.

|

Test equipment Test equipment

|

The equipment needed for the verification.

|

Location Type Location Type

|

Injection clamp.

|

Test Level Test Level

|

Specify the current substitution method.

|

Inputs Inputs

|

Add the current sensor as an input.

|

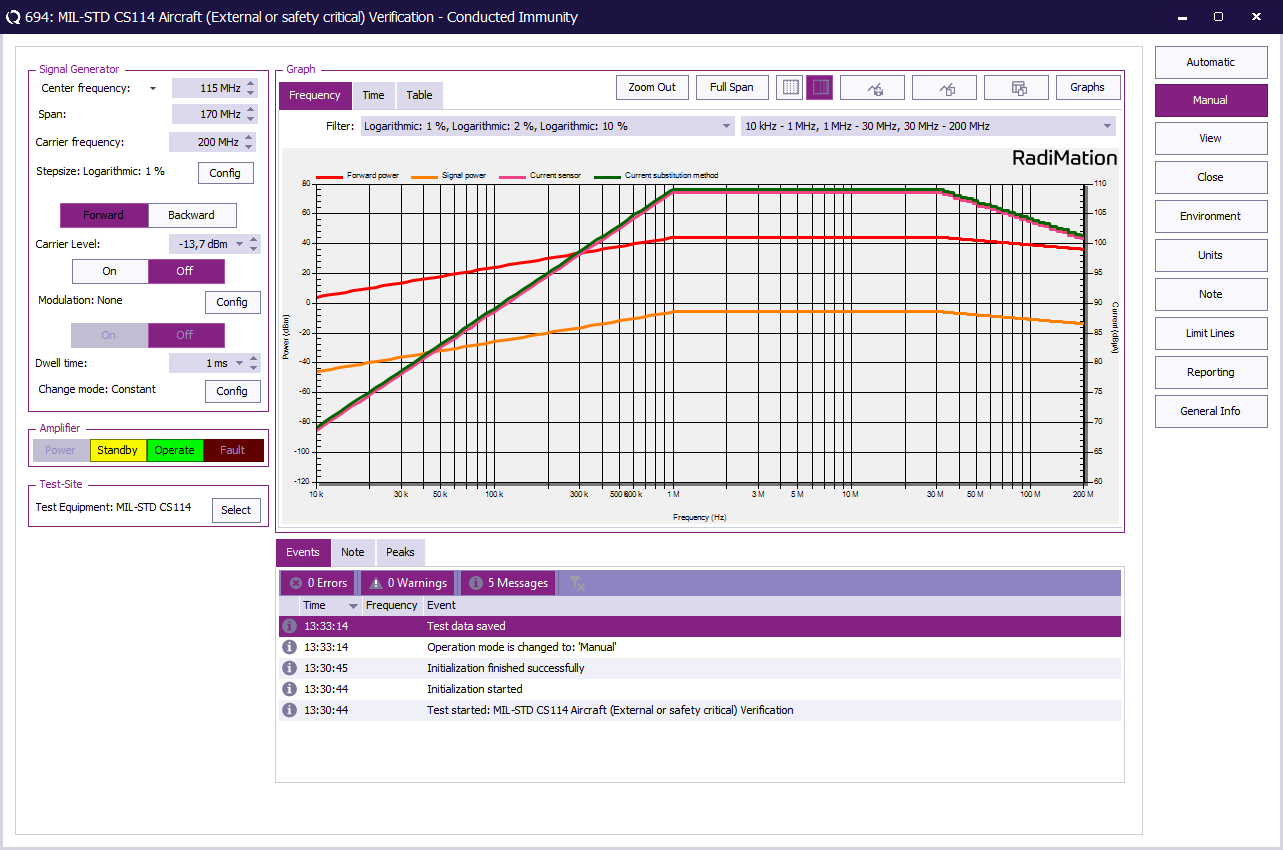

Run the verification test[edit]

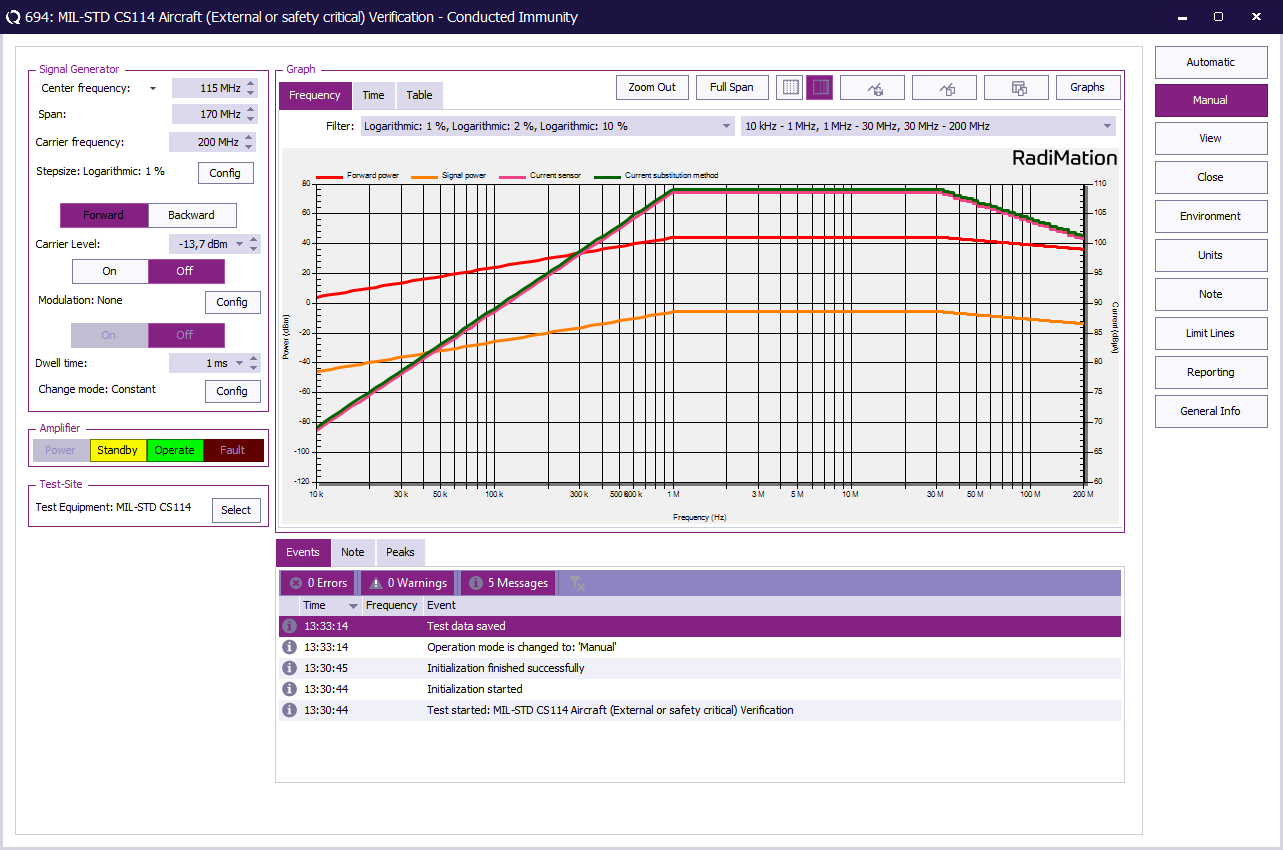

When all settings are configured press Start Test to run the verification test.

Verification result[edit]

With the result of the verification it should be possible to determine if the measured current is within the 3 dB tolerance of the current test limit as specified in 5.12.3.4.c

EUT Testing[edit]

Conclusion[edit]

File

File

New

New

Correction

Correction  Calibration

Calibration

System calibration

System calibration

Conducted immunity

Conducted immunity  Tests

Tests

Conducted Immunity

Conducted Immunity

Multiband

Multiband