Difference between revisions of "RadiMation Application Note 114"

(→How to measure data from the EUT using the Configurable AD Convertor device driver) |

(→How to measure data from the EUT using the Configurable AD Convertor device driver) |

||

| Line 6: | Line 6: | ||

Let's assume that the EUT is a central heating boiler, and that the temperature of the water inside the boiler should be measured and monitored. The central heating boiler has a serial port (which is connected to COM3 on the testing PC), and if the command: "TEMP?" is transmitted, the microcontroller on the boiler will respond with: "Temp: 46.5". | Let's assume that the EUT is a central heating boiler, and that the temperature of the water inside the boiler should be measured and monitored. The central heating boiler has a serial port (which is connected to COM3 on the testing PC), and if the command: "TEMP?" is transmitted, the microcontroller on the boiler will respond with: "Temp: 46.5". | ||

| − | The configuration in {{RadiMation}} can be separated in | + | The configuration in {{RadiMation}} can be separated in three steps: |

# Configure the [[Configurable AD Convertor]] device driver to retrieve the value from the measurement device. | # Configure the [[Configurable AD Convertor]] device driver to retrieve the value from the measurement device. | ||

# Plot the measured value during an immunity test using the correct unit. | # Plot the measured value during an immunity test using the correct unit. | ||

| − | # | + | # Running a test |

==Configuring the Configurable AD convertor== | ==Configuring the Configurable AD convertor== | ||

Revision as of 19:44, 30 January 2023

How to measure data from the EUT using the Configurable AD Convertor device driver

This Application Note explains how the Configurable AD Convertor can be used to monitor an EUT. With the Configurable AD convertor, any type of signal can be measured, monitored and plotted within RadiMation® during an immunity test.

Let's assume that the EUT is a central heating boiler, and that the temperature of the water inside the boiler should be measured and monitored. The central heating boiler has a serial port (which is connected to COM3 on the testing PC), and if the command: "TEMP?" is transmitted, the microcontroller on the boiler will respond with: "Temp: 46.5".

The configuration in RadiMation® can be separated in three steps:

- Configure the Configurable AD Convertor device driver to retrieve the value from the measurement device.

- Plot the measured value during an immunity test using the correct unit.

- Running a test

Configuring the Configurable AD convertor

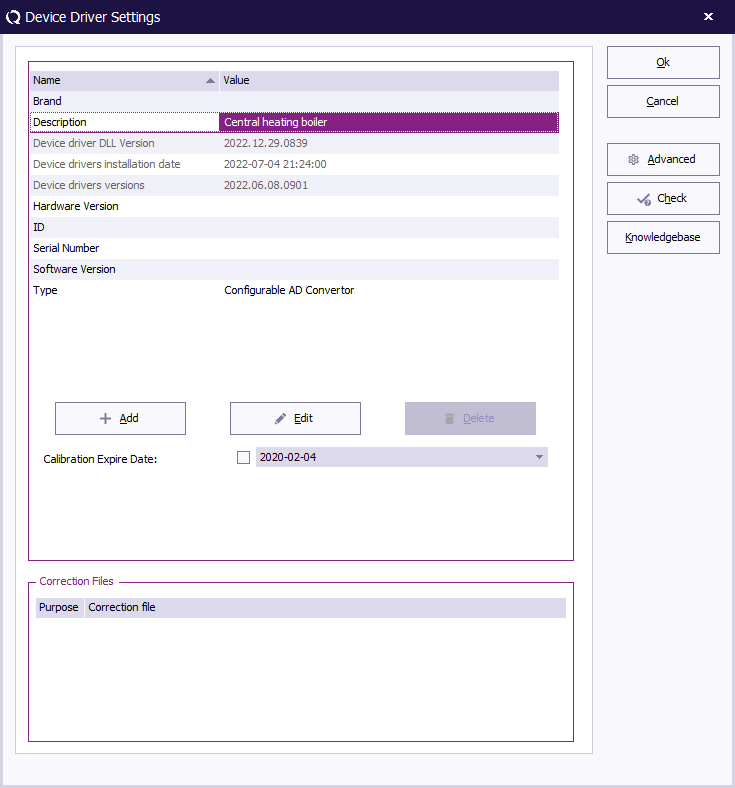

First create a new Configurable AD Convertor device driver. It is best to give this new device driver a descriptive description to identify it clearly for the task that it is used for. In this example 'Central heating boiler' would be a suitable name.

After the device driver is created, open the Advanced settings window of the new device driver, which allows to further specialise how the driver should communicate with the actual device.

Configure the commands for the initialisation of the device

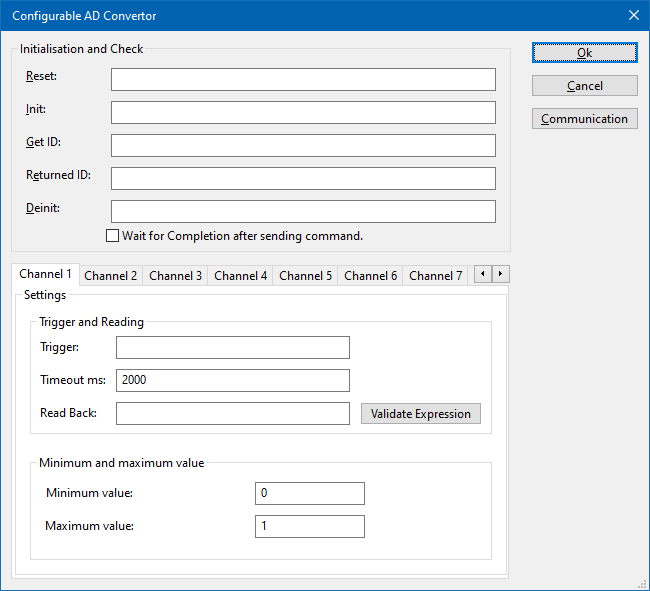

The Configurable AD Convertor device driver has several boxes, in which the remote programming commands can be specified, which should be transmitted to the measurement device on defined moments.

| The reset code that needs to be transmitted to device. When left blank, no command will be transmitted. |

| The command that is transmitted to initialise the configured device. When left blank, no command will be transmitted. |

| The query-command that is transmitted to retrieve the ID of the device. This is used to check if the device is connected. A commonly used SCPI command is: '*IDN?'. When left blank, no command will be transmitted. |

| If the checkbox is ticked, RadiMation® will wait for all the commands to complete, before it continues. This is achieved by also transmitting the SCPI query-command '*OPC?' to the device, and waiting for the response. |

None of these commands have to be specified, as the central heating boiler doesn't need to be initialized or deinitialized.

Configure the measurement and interpretation of the measured value

AD convertors can have multiple channels from which values can be read. The Configurable AD Convertor device driver is able to retrieve the values from up to 50 different channels from the measurement device. For each AD channel, an individual query-command can be specified, specific for the measurement value that should be retrieved. For this example we only need a single channel, as we are are only interested to retrieve the water temperature.

The configuration of the single channel can be configured on the Channel 1.

| The timeout (specified in milliseconds) that should be used to read the response from the device. We can leave this on the default 2000 milliseconds. |

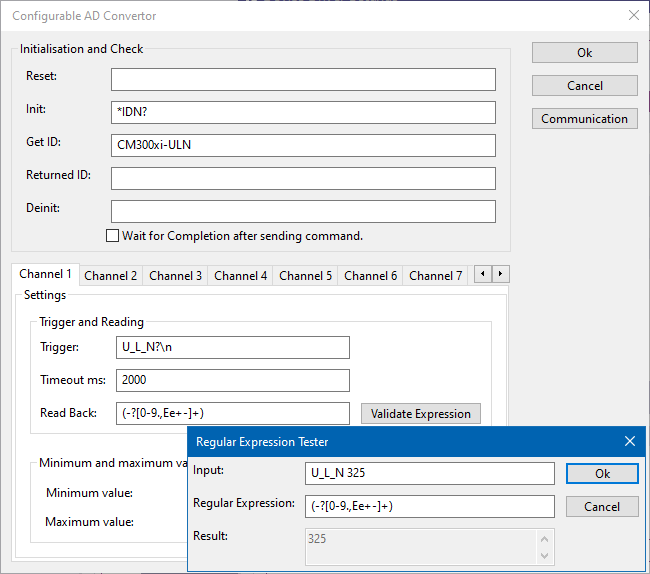

The regular expression that should be used to determine the numeric value in the response from the central heating boiler. As the response is something like: "Temp: 46.5", the regular expression can be: "Temp: ([0-9.]+)".

|

| Shows a small window where the expected response of the measurement device and a regular expression can be typed. |

The minimum and maximum measurable value of the measurement device can be specified to correctly scale the measured value. This will also be used to re-calculate the retrieved measurement value to another value with another unit.

| The lowest value of the channel that can be measured with the controlled measurement device. The value must be the same as filled in the EUT window. It normally is the best to configure this value to be 0. |

| The highest value of the channel that can be measured with the controlled measurement device. The value must be the same as filled in the EUT window. It normally is the best to configure this value to be 1. |

The correctness of the regular expression can be tested, verified and improved by using the Validate Expression tool within the configurable device driver. In the Regular Expression Tester, the following fields are available to verify the regular expression:

| Any text that is expected to be returned by the device. In this example this will be "Temp: 46.5" |

| The Regular expression that is being tested. For this example we can verify if the "Temp: ([0-9.]+)" regular expression is sufficient. |

| The numerical value that is determined by the device driver using the Regular Expression on the Input. This should show the 46.5 value that we are expecting. |

By changing the Input field, we can easily test if the regular expression is able to determine the correct water temperature.

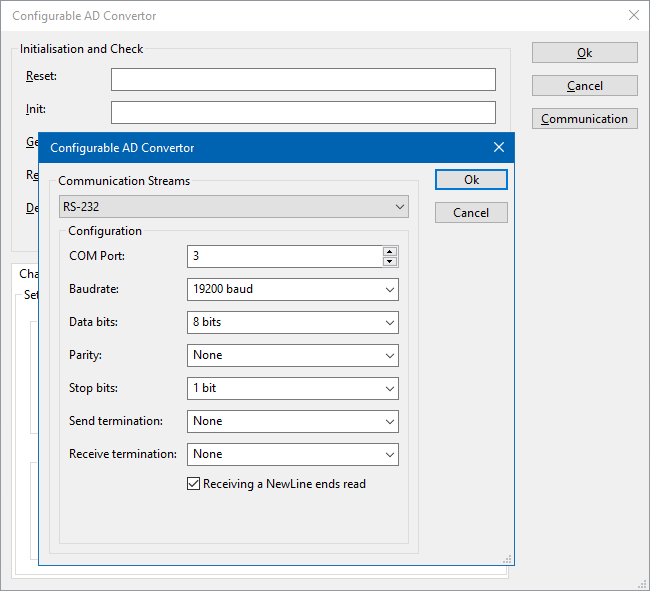

Specify the communication type

The correct settings for the communication with the measurement device (which is the actual EUT in this example) must also still be configured. The Configurable AD Convertor supports several communication types, which can be used to communicate with the measurement device. Click on the Communication button, to open the configuration dialog to specify the actual details of the medium to use for the communication. Depending on the connection that is used, select the correct Communication Stream, and configure the parameters correspondingly to communication settings that are used by device. Different Communication Streams are available, which are described in more detail in the Communication settings section of Chapter 15.

In this example the RS-232 stream is selected, and the COM Port is set to COM3 to allow communication with the central heating boiler.

After this last configuration, the device driver is configured correctly and all configuration windows can be closed.

Plot the measured value during an immunity test using the correct unit

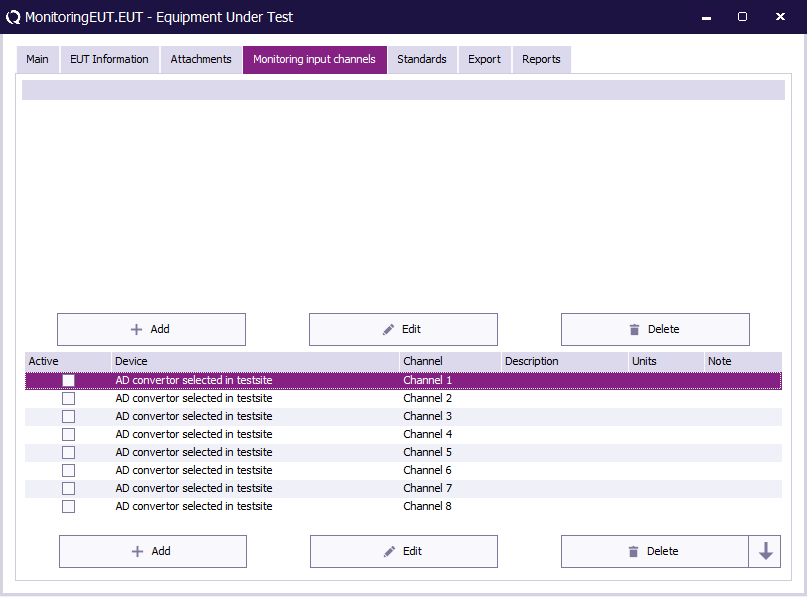

Create a new monitoring input channel

- The monitoring functionality is applied to the EUT. Therefor we first need to have an EUT file opened.

- In the opened EUT file, we can select the Monitoring input channels tab.

- Double click an existing input channel or add a new input by using the add button.

- A new window will open to configure the monitoring input channel.

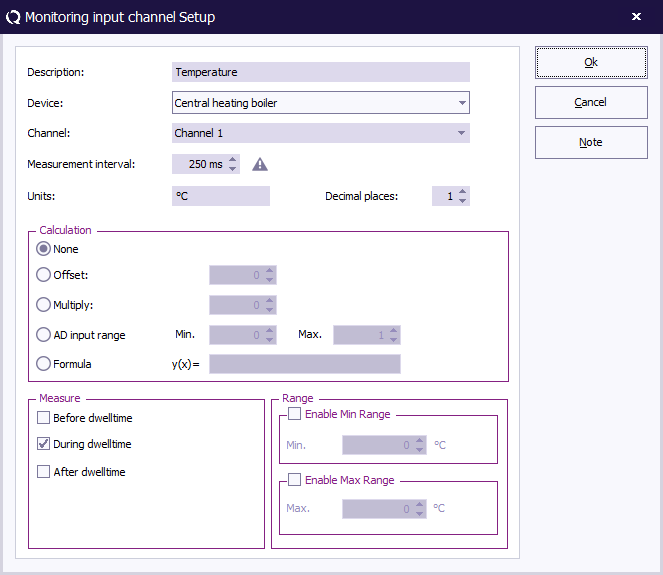

Configure a monitoring input channel

- At the device menu, the newly configured AD convertor can be selected.

- The selected AD channel must be selected.

- The Unit type can be specified as text.

- With Calculation, the raw value from the AD convertor can be modified to match the preferred unit. More information can be found here.

- The Monitoring Input channel description will be shown in the graph title.

- After pressing Ok to save the configurations, ensure that the configured monitoring channel is marked as Active in the monitoring input channels list.

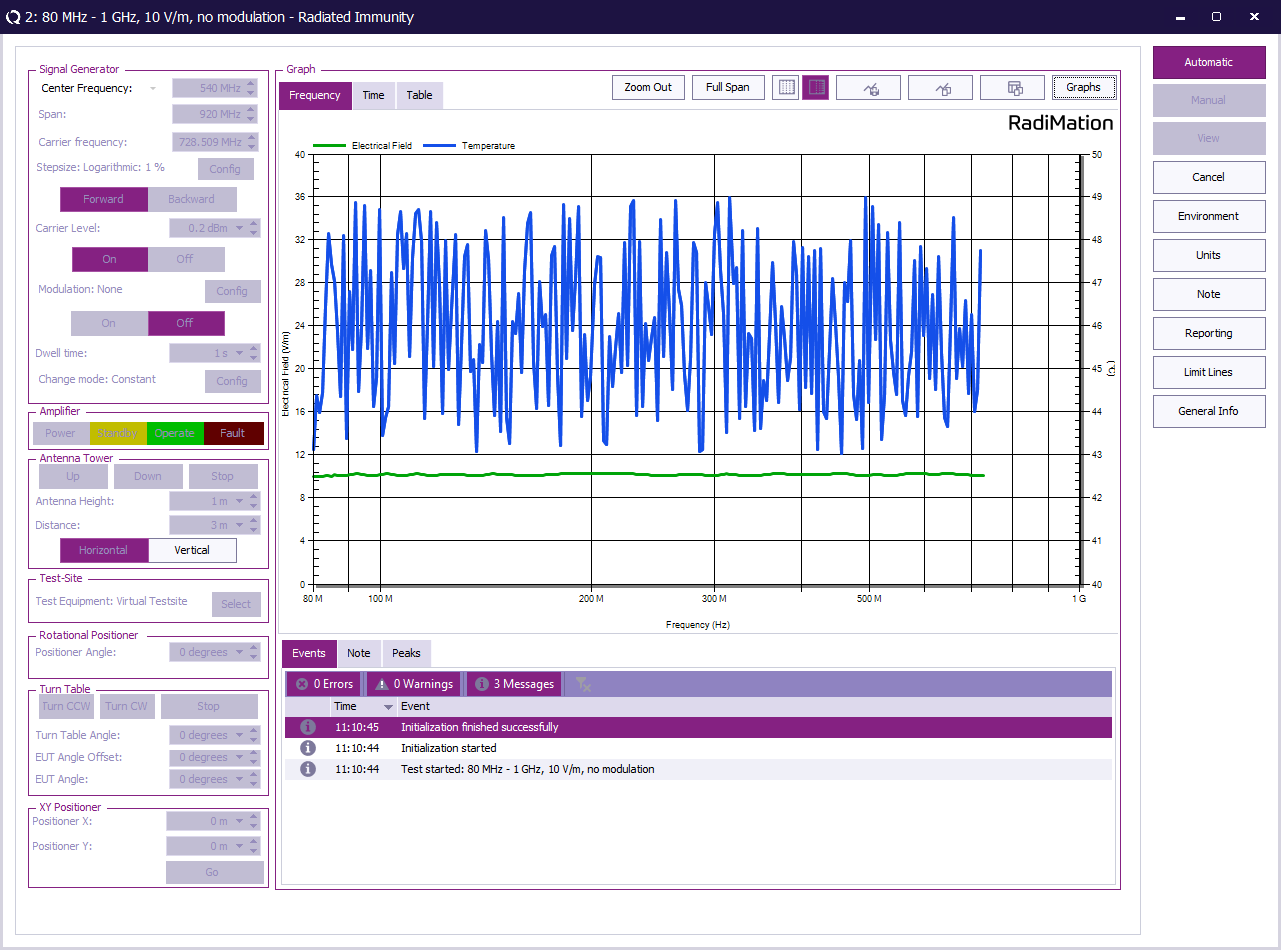

Running a test

When an immunity test is performed, RadiMation will also measure the value from the measurement device and it will plot the line(s) of the activated monitoring input channel(s). By switching to the Table tab, the measurement values will be shown in a tabular style.